Electric kiln used for jun porcelain firing and jun porcelain firing method

A technology of electric kiln and Jun porcelain, which is applied in the field of ceramic production, can solve the problems that conventional electric kilns cannot be fired with Jun porcelain, and achieve the effects of improving kiln conversion efficiency, stable quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

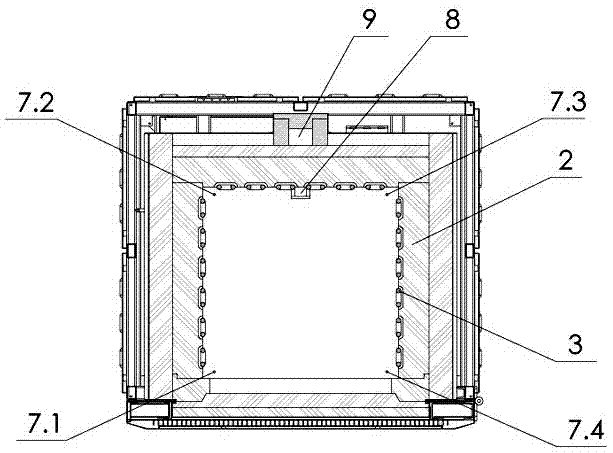

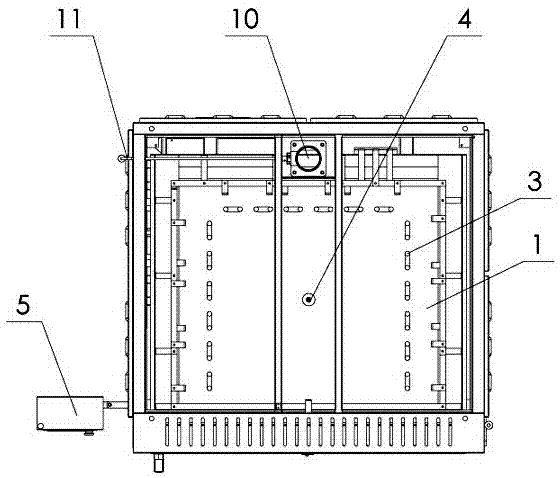

[0020] Such as figure 1 As shown, the electric kiln of the present invention includes a furnace body 1 for placing Jun porcelain to be sintered. The furnace body 1 is installed in a kiln shell with cooling holes on the top cover and side walls and rollers installed on the bottom. The front side of the furnace body 1 is a furnace door, on which an observation hole is provided. Such as figure 2 As shown, the inside of the furnace body 1 is provided with a multi-layer thermal insulation lining layer 2 made of different materials, wherein the innermost layer is made of high temperature resistant alumina fiber material. A U-shaped high-purity silicon carbon electric heating rod 3 is installed on the left side wall, the right side wall and the rear side wall of the furnace body 1, and the electric heating rod 3 is installed on the furnace body 1 The transformer and other electrical appliances at the bottom are connected; a temperature measuring thermocouple 4 is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com