Hydrolysis-resistant dimer acid type polyurethane and preparation method thereof

A dimer acid-type, hydrolysis-resistant technology, applied in the field of polyurethane, can solve the problems of no obvious reduction in petrochemical resources and a small degree of improvement in hydrolysis resistance, achieve obvious application and market prospects, improve hydrolysis resistance and Water resistance, reduce the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation polybasic acid is dimer acid, the polyester polyol of functional group mol ratio COOH / OH=1: 1.10: with 583 parts of dimer acid (high-purity dimer acid, acid value 193mgKOH / g, welfare resin factory of Guangrao County) and 105 parts of neopentyl glycol were added into the reactor, and the temperature was raised with stirring under a nitrogen atmosphere. React at 120°C for 2h, 140°C for 1h, and 175°C for 2h. Then the temperature was raised to 210°C for another 4 hours, and the acid value was measured by sampling. The acid value was equal to 13 mgKOH / g, and the nitrogen flow was stopped, and vacuum was drawn. React under vacuum for 2 hours, take a sample to measure the acid value, the acid value is 0.48mgKOH / g, the output is light brown liquid, the hydroxyl value is 42.32mgKOH / g, and polyester polyol is obtained.

[0030] Preparation of dimer acid polyurethane:

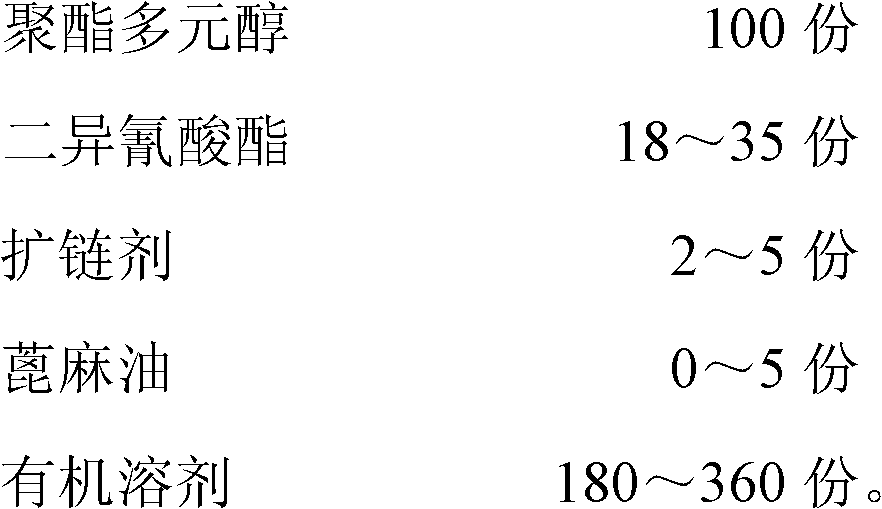

[0031] (1) Prepolymerization reaction: After dehydrating 100 parts of polyester polyol under r...

Embodiment 2

[0036] The preparation polybasic acid is dimer acid, the polyester polyol of functional group molar ratio COOH / OH=1: 1.55: with 583 parts of dimer acid (high-purity dimer acid, acid value 193mgKOH / g, Guangrao County welfare resin factory, under Same), 100 parts of neopentyl glycol and 80 parts of 1,6-hexanediol were added into the reaction kettle, stirred and heated under nitrogen atmosphere. React at 120°C for 2h, 140°C for 1h, and 175°C for 2h. Then the temperature was raised to 210°C for another 4 hours, and the acid value was measured by sampling. The acid value was equal to 12 mgKOH / g, and the nitrogen flow was stopped, and the vacuum was drawn. React under vacuum for 2 hours, take a sample to measure the acid value, the acid value is 0.57mgKOH / g, the output is light brown liquid, the hydroxyl value is 54.82mgKOH / g, and polyester polyol is obtained.

[0037] Preparation of dimer acid polyurethane:

[0038](1) Prepolymerization reaction: After dehydrating 100 parts of po...

Embodiment 3

[0043] Preparing polybasic acid is that dimer acid accounts for 89% of mixed polybasic acid weight, the polyester polyol of functional group mol ratio COOH / OH=1: 1.48: with 408 parts of dimer acid, 52 parts of adipic acid, 120 parts of neopentyl glycol and 20 parts of ethylene glycol are added in the reaction kettle, and reacted according to the method described in Example 1 to obtain an acid value of 0.62 mgKOH / g, the discharge is a light brown liquid, and the hydroxyl value is 49.43 mgKOH / g to obtain a polyester polyol .

[0044] Preparation of dimer acid polyurethane:

[0045] (1) Prepolymerization reaction: After dehydrating 100 parts of polyester polyol at 120°C for 2 hours under reduced pressure, the temperature was lowered to 80°C, and 35 parts of N,N-dimethylformamide, 35 parts of dioxane and 12 parts of 1 , 6-hexamethylene diisocyanate, reacted at 80°C for 1h to obtain a prepolymer;

[0046] (2) chain extension reaction: add 2 parts of ethylene glycol in the prepoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com