Method for processing microstructure of silicon and metal composite material

A technology of metal composite materials and processing methods, which is applied in the field of microstructure production of silicon and metal composite materials, can solve the problems of inability to provide plastic deformation ability and limited improvement, and achieve perfect electroformed metal structure, good repeatability, and easy The effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

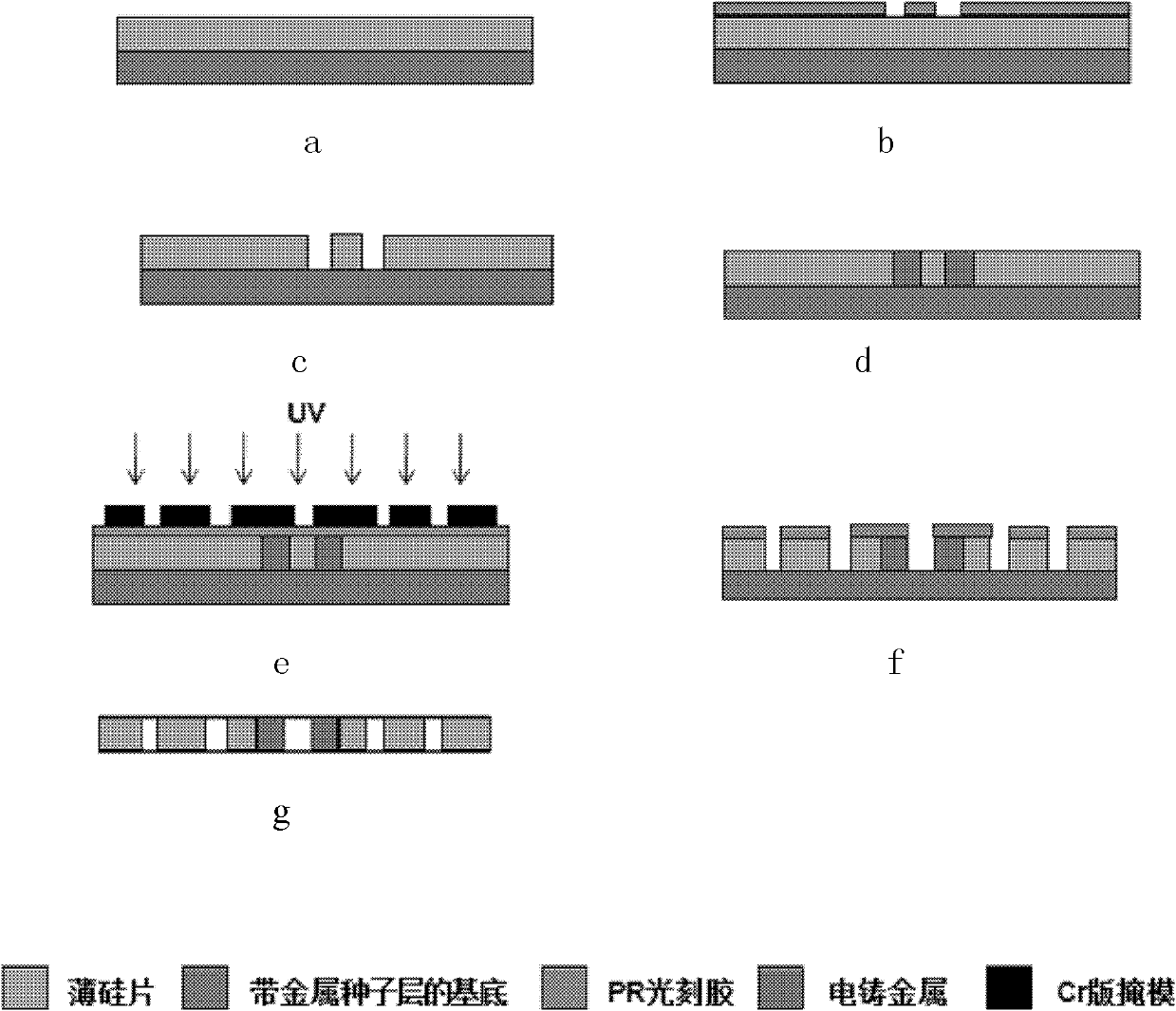

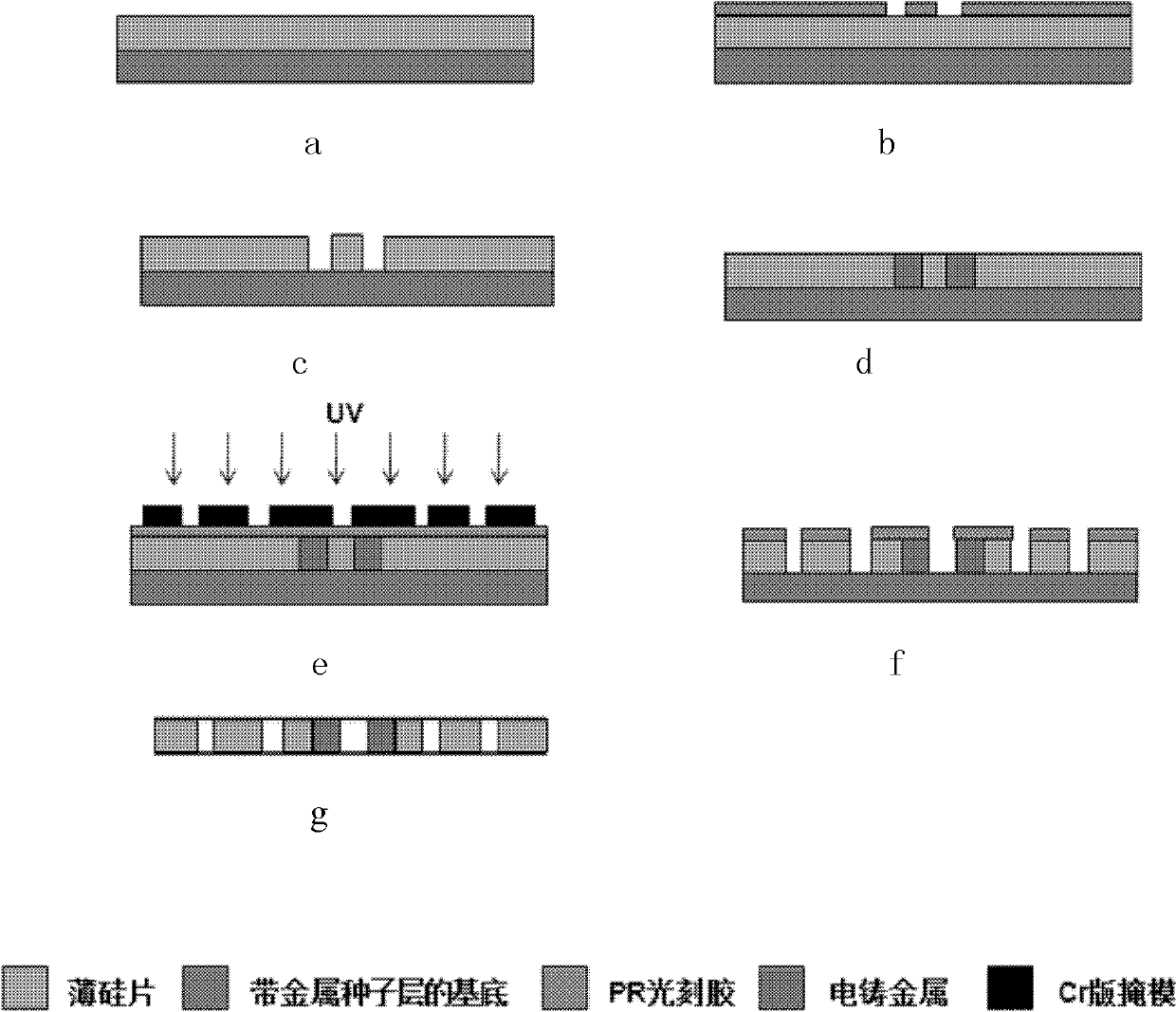

[0026] (1) Thin silicon wafer is eutectically bonded to a silicon substrate containing a metal seed layer, see figure 1 (a);

[0027] a) Select a thin silicon wafer with a size of 3", a thickness of 100um, and a crystal orientation of ;

[0028] b) Routine cleaning of the surface of the thin silicon wafer: add deionized water for ultrasonic cleaning for 10 minutes, then rinse with deionized water; add acetone and absolute ethanol for ultrasonic cleaning and then clean with deionized water; boil concentrated sulfuric acid and add hydrogen peroxide Wash with deionized water after rinsing with dilute hydrofluoric acid; rinse with deionized water after rinsing with dilute hydrofluoric acid; 2 Dry with infrared light under atmosphere;

[0029] c) Sputtering a Ti / Au / Ti metal seed layer on a silicon substrate (thickness 500um, crystal orientation ) with a thickness of 20 / 200 / 20 nm;

[0030] d) Realize the eutectic bonding of Si / Au in a vacuum nitrogen oven: temperature 420-450 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com