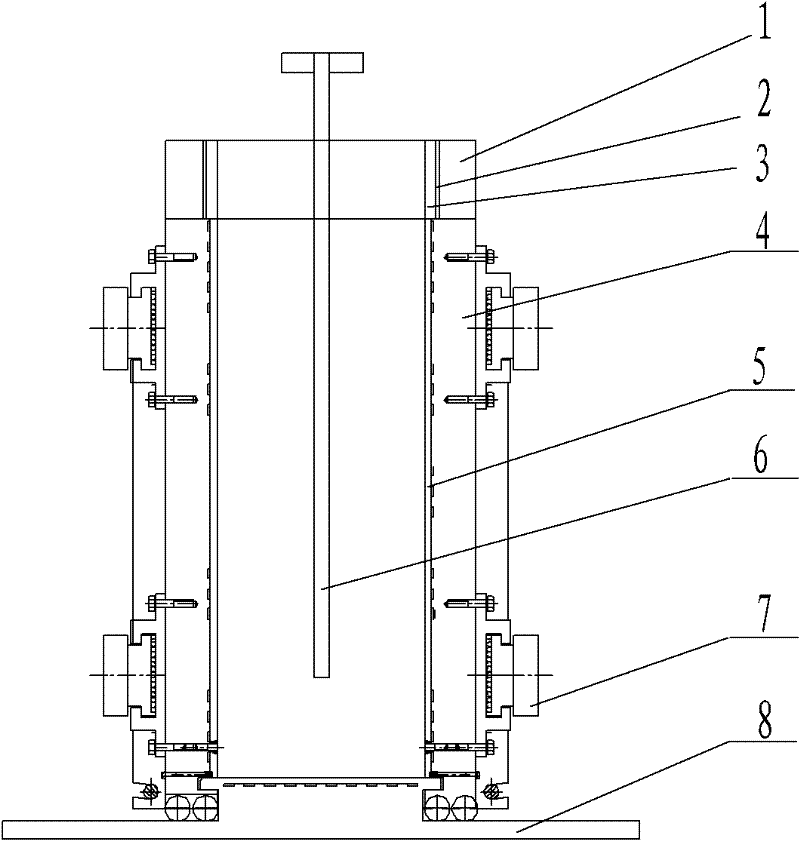

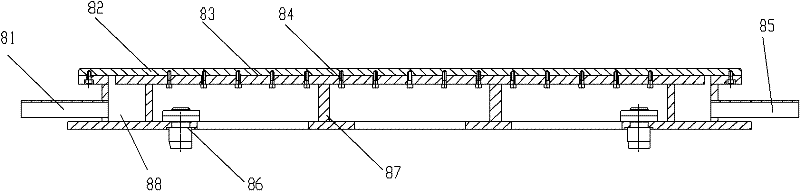

Manufacturing tool of high-compact wide and thick plate blank for wide and thick plate rolling mill and method

A technology for manufacturing tooling and manufacturing methods, which is applied in the field of manufacturing wide and thick slabs for wide and thick plate rolling mills. It can solve problems such as oxidation inclusions, looseness, and cracks in slabs, and achieve the effects of uniform organization, crack elimination, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Double-layer thermal insulation riser is adopted, the inner layer is 80mm thick lightweight high alumina brick, and the outer layer is 15mm thick thermal insulation cotton; the molten steel temperature is 1590°C, and the refining bag is refined by blowing argon outside the furnace to strictly control phosphorus, Sulfur content, P≤0.015%, S≤0.008%, pouring molten metal weight 60 tons, pouring time 25min, pouring temperature 1560°C. Fill the cavity with argon before pouring, and pour under the protection of argon. After 30 minutes of pouring, increase the pressure of the hydraulic cylinder to gradually increase the pressure of a single hydraulic cylinder to 50 tons. Keep the pressure for 3h and start to decompress. After 20 minutes, the pressure of the hydraulic cylinder is converted into tension, so that the movable mold gradually leaves the slab.

[0060]In terms of weight percentage, the composition of the slab material is: C 0.2%, Si 0.65%, Mn 1.2%, P≤0.015%, S≤0.00...

Embodiment 2

[0064] Double-layer insulation risers are adopted, the thickness of the inner layer of light high-alumina bricks is 60mm, and the thickness of the outer layer of insulation cotton is 25mm; the molten steel is released at a high temperature, and the temperature of the furnace is 1580°C, and it is refined by blowing argon outside the furnace in the refining bag, strictly controlled Phosphorus and sulfur content, P≤0.015%, S≤0.008%, pouring molten metal weight 58 tons, pouring time 25min, pouring temperature 1550°C. Fill the cavity with argon before pouring, and pour under the protection of argon. After 50 minutes of pouring, increase the pressure of the hydraulic cylinder to gradually increase the pressure of a single hydraulic cylinder to 80 tons. Keep the pressure for 3h and start to decompress. After 30 minutes, the pressure of the hydraulic cylinder is converted into tension, so that the movable mold gradually leaves the slab.

[0065] In terms of weight percentage, the co...

Embodiment 3

[0068] Double-layer insulation risers are adopted, the thickness of the inner layer of light high-alumina bricks is 100mm, and the thickness of the outer layer of insulation cotton is 30mm; the temperature of the molten steel is 1595°C, and the refining bag is refined by blowing argon outside the furnace to strictly control the content of phosphorus and sulfur , P ≤ 0.015%, S ≤ 0.008%, the weight of the poured molten metal is 62 tons, the pouring time is 28 minutes, the pouring temperature is 1565°C, the cavity is filled with argon before pouring, and the pouring is carried out under the protection of argon. After pouring for 60 minutes, increase the pressure of the hydraulic cylinder to gradually increase the pressure of a single hydraulic cylinder to 100 tons. Keep the pressure for 3h and start to decompress. After 10 minutes, the pressure of the hydraulic cylinder is converted into tension, so that the movable mold gradually leaves the slab.

[0069] In terms of weight per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com