Electrostatic chuck

An electrostatic chuck and electric power technology, which is applied to holding devices, circuits, and electrical components using electrostatic attraction, can solve the problems of large-scale internal power supply, pollution leakage current of peripheral equipment, etc. The effect of reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, preferred embodiments of the present invention will be specifically described with reference to the drawings. In addition, this invention is not limited to the following description.

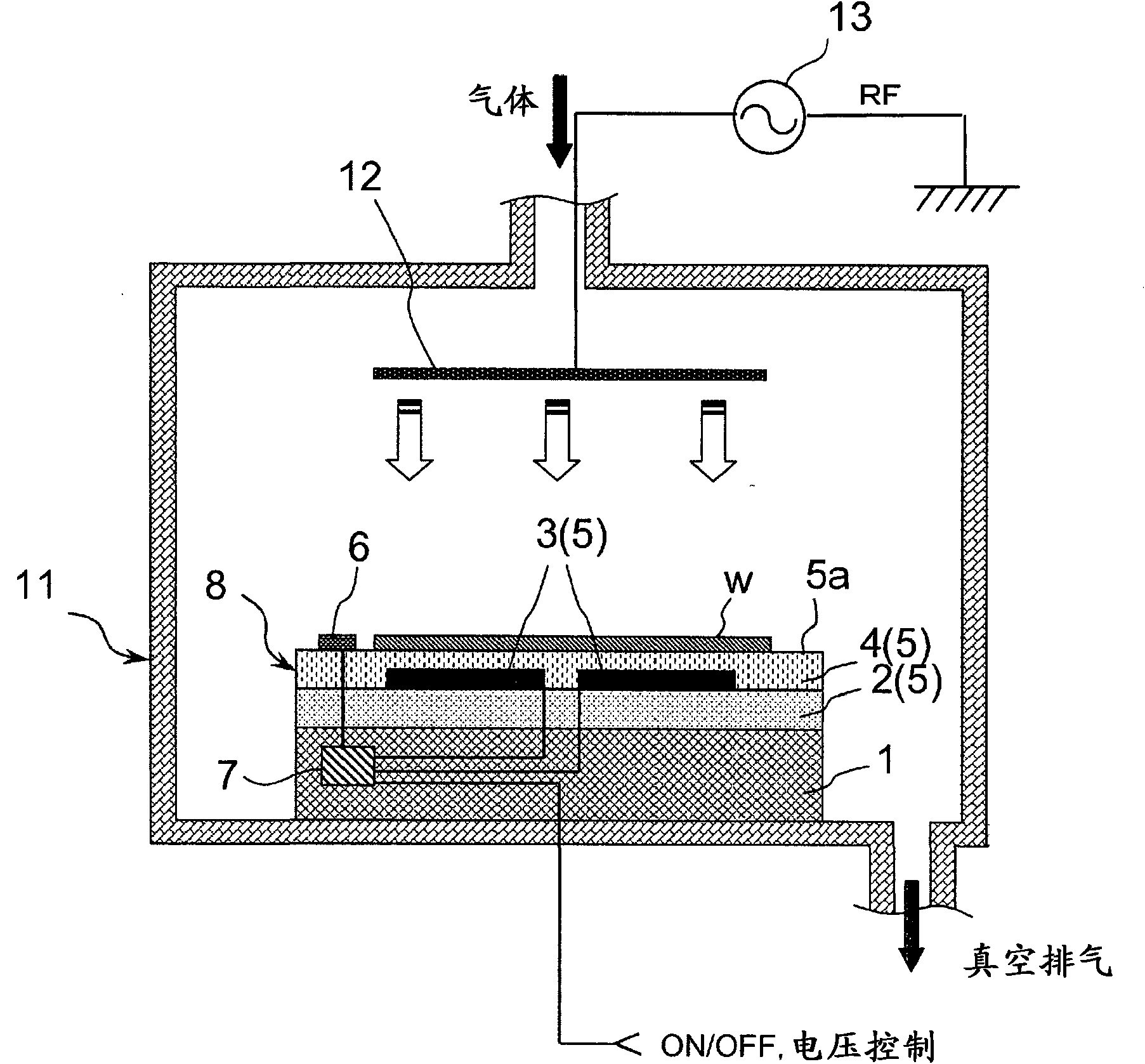

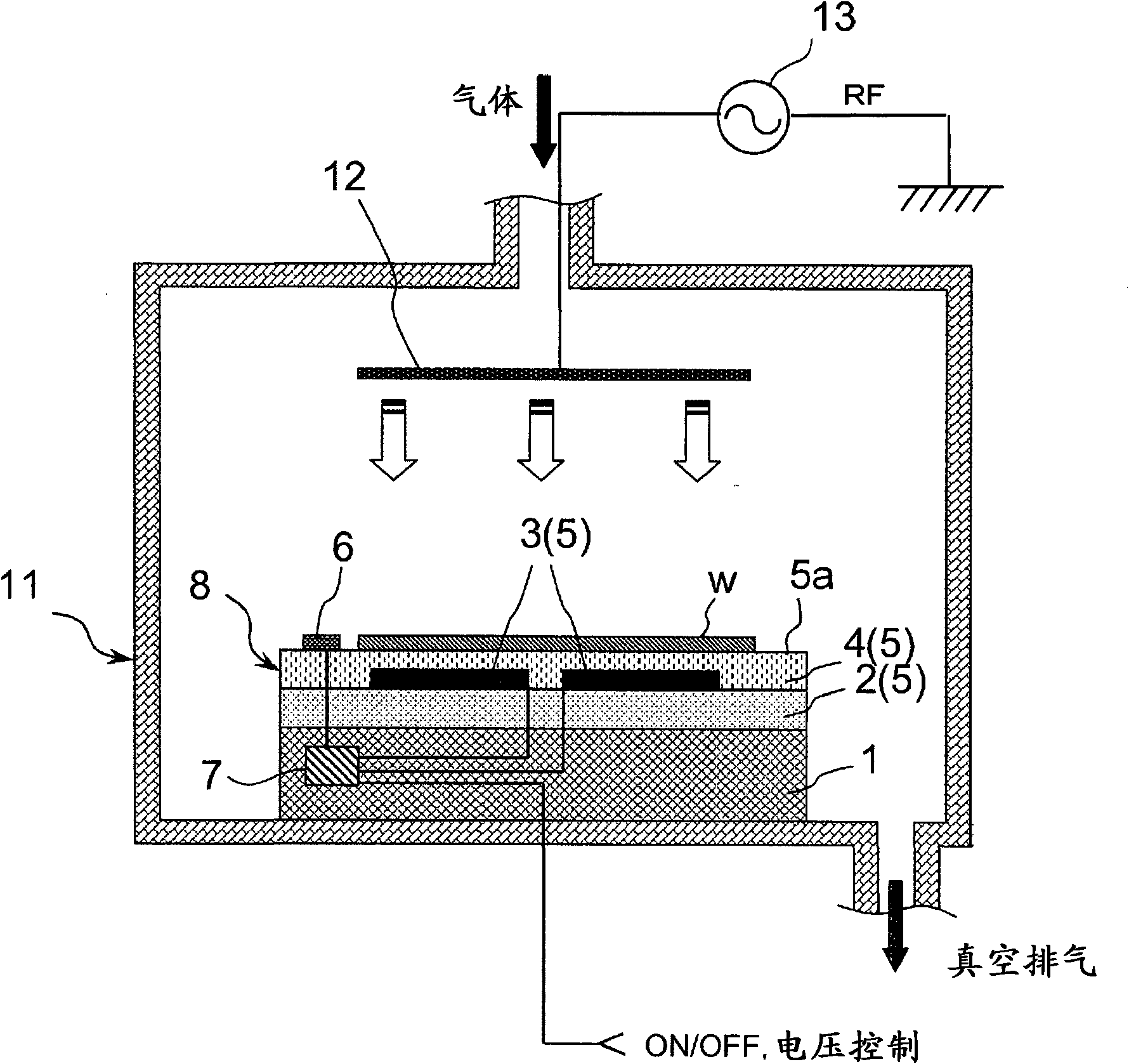

[0026] figure 1 It is a schematic cross-sectional view showing a state in which a silicon wafer w is sucked and held by using the electrostatic chuck 8 of the present invention in a parallel plate type plasma etching apparatus 11 and an etching process of the silicon wafer w is performed. In the electrostatic chuck 8 according to this embodiment, the electrode sheet 5 is pasted on the upper surface side of an aluminum metal base 1 with a thickness of 12 mm and a diameter of 340 mm. The electrode sheet 5 is formed by stacking the lower insulating layer 2 and the upper insulating layer 4 composed of a polyimide film with a thickness of 100 μm and a diameter of 298 mm on the upper and lower surfaces of the adsorption electrode 3, wherein the adsorption electrode 3 is made of copper wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com