Ultra-low dielectric constant material film and preparation method thereof

A technology of ultra-low dielectric constant and material thin film, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of thermal volatilization of precursors and unsuitability of ring precursors, etc., and achieve good electrical properties and large breakdown electric field Strength, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

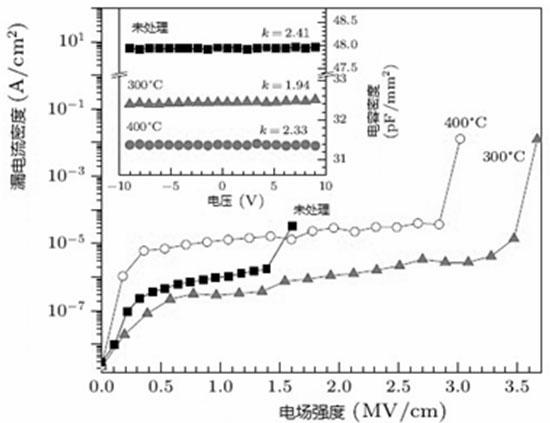

[0031] SiOCH material films with different properties can be obtained by using the method for preparing ultra-low dielectric constant material films provided by the present invention. The following description is an example of preparing SiOCH material films using the method proposed by the present invention. Specific steps are as follows:

[0032] 1. Provide a low-resistance monocrystalline silicon substrate and perform standardized cleaning.

[0033] 2. Preparation of precursors for ultra-low dielectric constant material films: 2,4,6,8-tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane (TVTMCTS), the purity of which is as follows It is 99.7wt%, and this precursor monomer has a single ring structure, consisting of eight Si-O bonds and four vinyl groups.

[0034] 3. A layer of precursor thin film is formed on the above-mentioned low-resistance single crystal silicon substrate by spin coating, which is named SiOCH thin film. During the spin coating process, the rotation speed wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com