Method for preparing copper-indium-gallium-selenium thin film serving as light absorbing layer of solar cell

A technology of solar cells and copper indium gallium selenide, which is applied in coatings, circuits, electrical components, etc., can solve the problems of potential safety hazards, uneven distribution of selenium, and reduced utilization of selenium, so as to reduce production costs and simplify the preparation process , The effect of component segregation improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

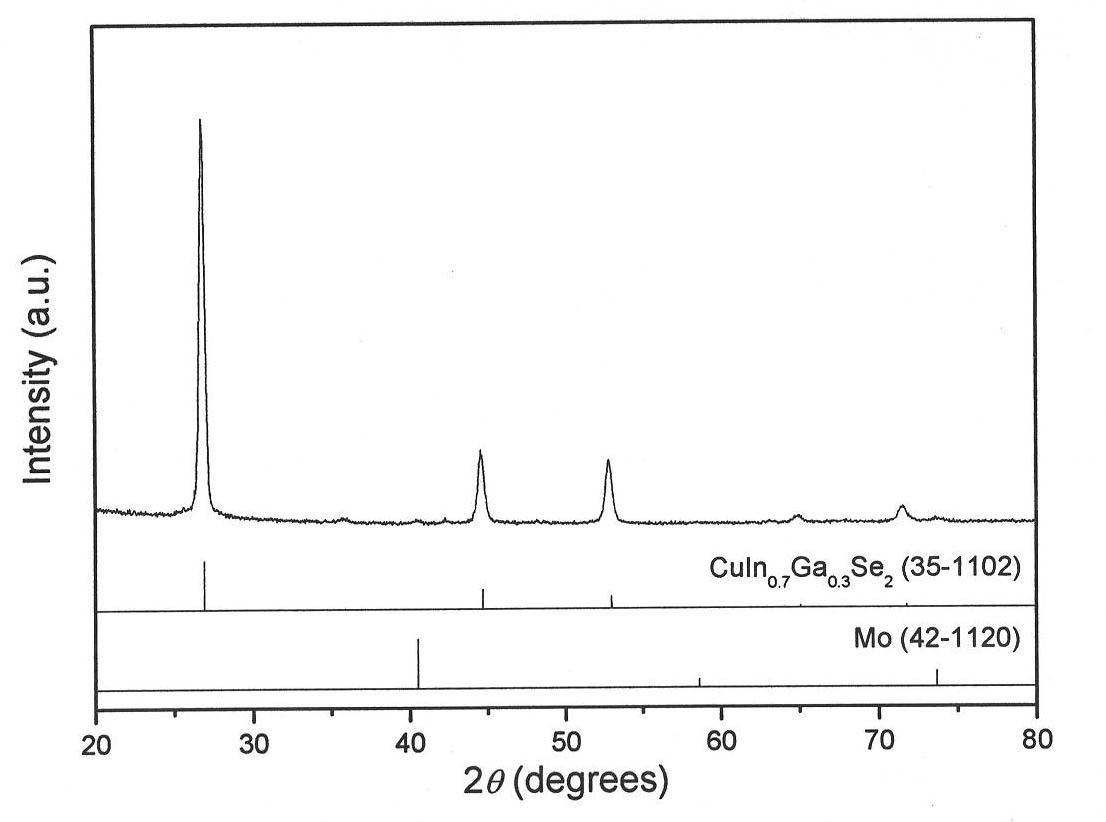

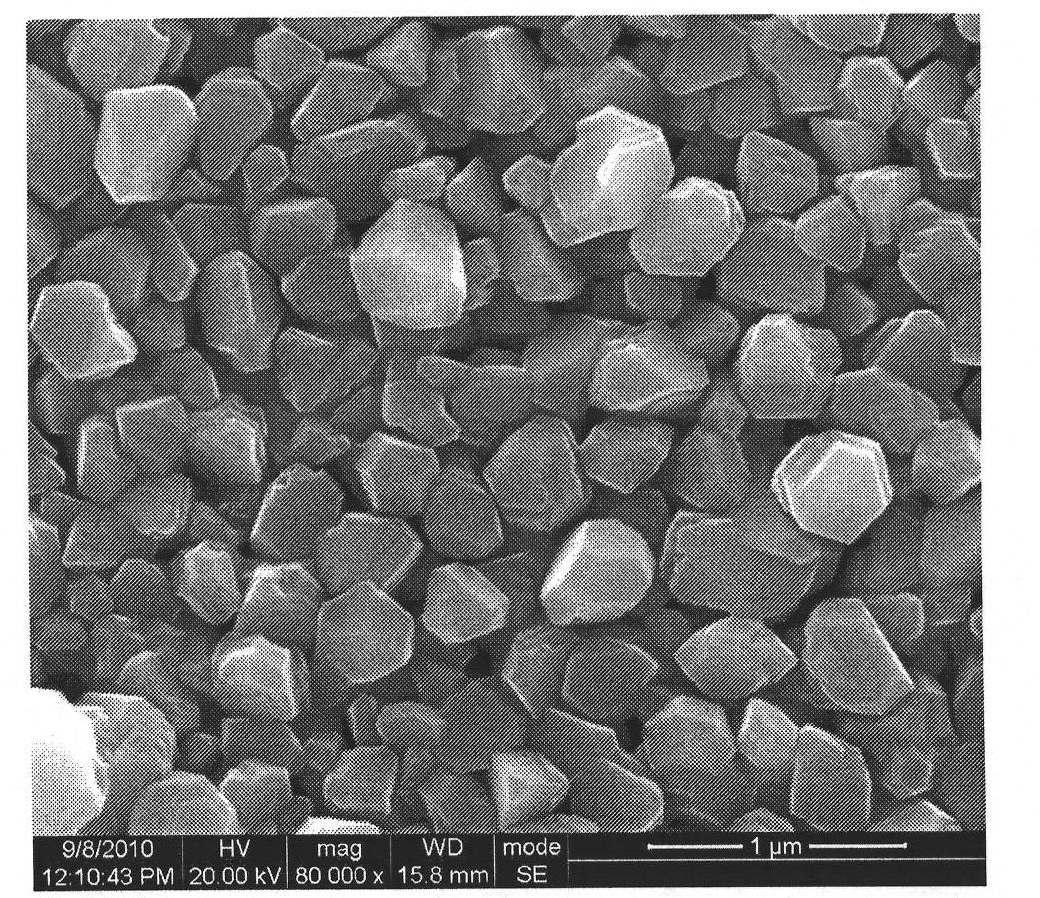

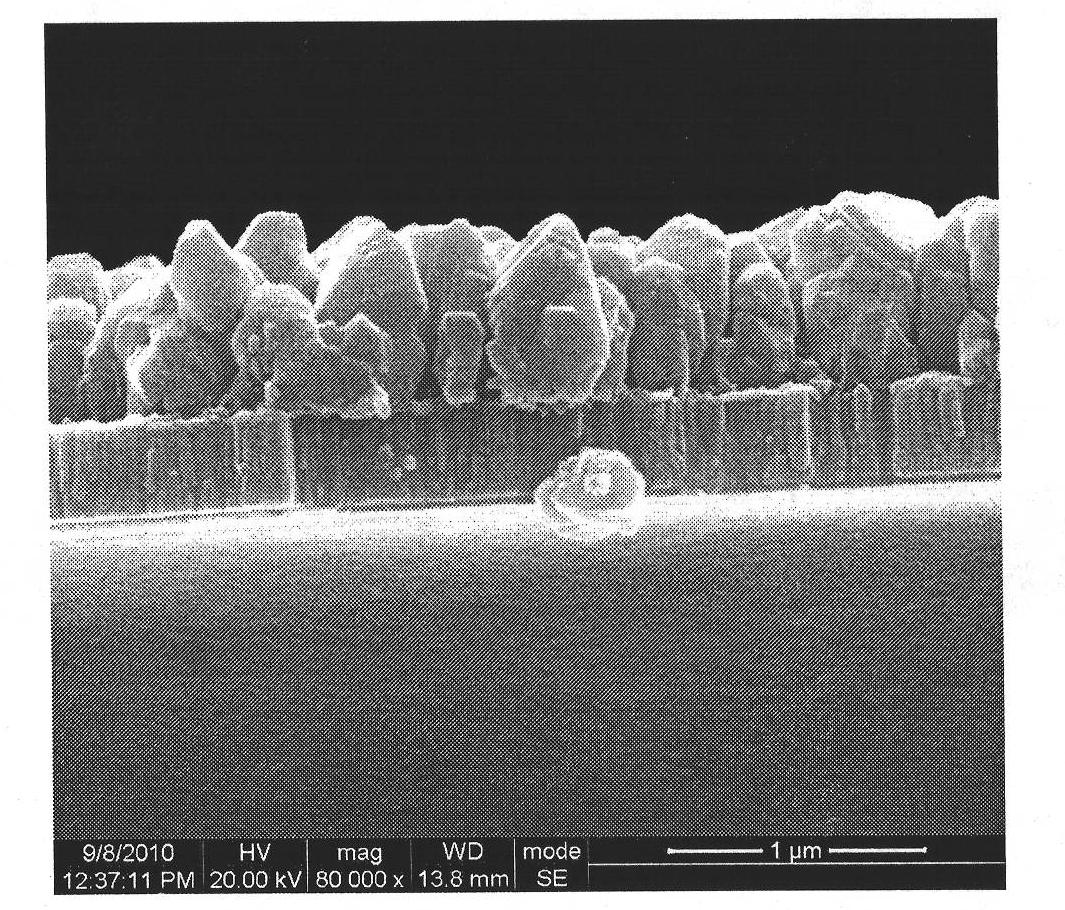

Image

Examples

Embodiment example 1

[0031] A method for preparing a copper indium gallium selenide thin film used as a light absorbing layer of a solar cell, the preparation steps are as follows:

[0032] (1) Install the Mo target and the CIGS target in the magnetron sputtering chamber, and install the cleaned soda-lime glass substrate, and then vacuumize the chamber to 1×10 -3 Below Pa, then feed 99.999% high-purity Ar gas, and use a DC power supply to sputter a double-layer Mo film with a total thickness of 0.5 μm on the substrate. The sputtering conditions are: the substrate rotation speed is 12rpm, and the substrate temperature is 550 ℃, the target base distance is 9cm, the flow rate of Ar gas is 100SCCM, the current of the DC power supply is 0.6A, the voltage is 210V, the sputtering pressure of the first layer Mo is 2Pa, and the corresponding sputtering time is 10min, the second layer Mo The sputtering pressure is 1Pa, and the corresponding sputtering time is 10min;

[0033] (2) After preparing the Mo laye...

Embodiment example 2

[0037] A method for preparing a copper indium gallium selenide thin film used as a light absorbing layer of a solar cell, the preparation steps are as follows:

[0038] (1) Install the Mo target and the CIGS target in the magnetron sputtering chamber, and install the cleaned soda-lime glass substrate, and then vacuumize the chamber to 1×10 -3 Below Pa, then feed 99.999% high-purity Ar gas, and use a DC power supply to sputter a double-layer Mo film with a total thickness of 0.5 μm on the substrate. The sputtering conditions are: the substrate rotation speed is 12rpm, and the substrate temperature is 100 ℃, the target base distance is 9cm, the flow rate of Ar gas is 100SCCM, the current of the DC power supply is 0.4A, the voltage is 140V, the sputtering pressure of the first layer Mo is 3Pa, and the corresponding sputtering time is 5min, the second layer Mo The sputtering pressure is 0.5Pa, and the corresponding sputtering time is 15min;

[0039] (2) After preparing the Mo lay...

Embodiment example 3

[0043] A method for preparing a copper indium gallium selenide thin film used as a light absorbing layer of a solar cell, the preparation steps are as follows:

[0044] (1) Install the Mo target and the CIGS target in the magnetron sputtering chamber, and install the cleaned soda-lime glass substrate, and then vacuumize the chamber to 1×10 -3 Below Pa, then feed 99.999% high-purity Ar gas, and use a DC power supply to sputter a double-layer Mo film with a total thickness of 0.5 μm on the substrate. The sputtering conditions are: the substrate rotation speed is 8rpm, and the substrate temperature is 450 ℃, the target base distance is 9cm, the flow rate of Ar gas is 100SCCM, the current of the DC power supply is 0.6A, the voltage is 210V, the sputtering pressure of the first layer Mo is 2Pa, and the corresponding sputtering time is 10min, the second layer Mo The sputtering pressure is 0.2Pa, and the corresponding sputtering time is 15min;

[0045] (2) After preparing the Mo lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com