Preparation method of hyaluronic acid

A technology of hyaluronic acid and JM109 is applied in the field of engineering Escherichia coli to produce hyaluronic acid, which can solve the problems of resource shortage and low safety of hyaluronic acid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

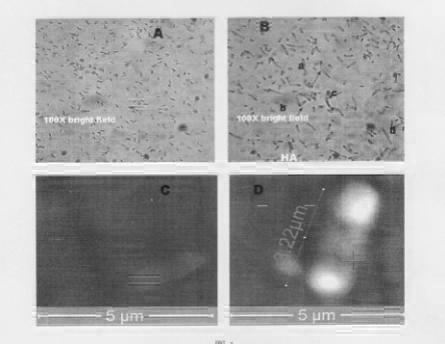

[0038] Shake flask culture synthesis of hyaluronic acid in pHK / JM109:

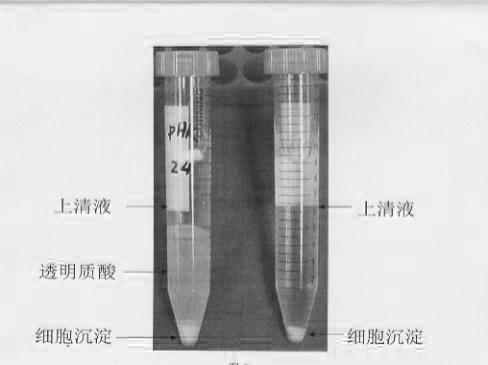

[0039] In a 500ml Erlenmeyer flask, contain 50 mM K in a total volume of 100ml 2 HPO 4 ·3H 2 O, (pH7.0) 4mM g / L MgSO4 7H2O, 20mM / L citric acid, 1mM MnCl2, 300mM glucose, 50 mM nitrogen acetylglucosamine (GlcNAc), 10mM lactose, 10g / L glycerol, 5g / LCasamino acid (hydrolyzed Casamino acids) added to the system expressed pmHas and kfi The pHK / JM109 of D makes the bacterial cell concentration reach 5% (W / V), the fermentation condition is 30°C, 250rpm, and the pH is adjusted to neutral with 28% (V / V) ammonia water, and the fermentation reaction time is 36 hours . The determined HA content can reach about 0.75-1 g / L (see figure 2 ).

Embodiment 2

[0041] In a 2500l Erlenmeyer flask, with a total volume of 500ml containing 25 mM K 2 HPO 4 ·3H 2 O, (pH6.5) 2mM g / L MgSO4 7H2O, 40mM / L citric acid, 2mM MnCl2, 400mM glucose, 75 mM nitrogen acetylglucosamine (GlcNAc), 5mM lactose, 30g / L glycerol, 3g / L hydrolyzed casein Amino acid (Casamino acid) system added to the expressed pmHas and kfi The pHK / JM109 of D makes the bacterial cell concentration reach 4% (W / V), the fermentation condition is 33°C, 250rpm, and the pH is adjusted to neutral with 28% (V / V) ammonia water, and the fermentation reaction time is 30 hours .

[0042] It has been determined that the HA content can reach about 0.7-8.5 g / L. Because the synthesis of HA requires oxygen and relatively stable pH, in order to further improve the output of engineering bacteria, the present invention has carried out the cultivation of HA synthesis in a fermenter.

Embodiment 3

[0044] Fermentation tank synthesis of hyaluronic acid in pHK / JM109:

[0045] Pick up 3-5 streaked and overnight cultured pHK / JM109 single colonies from the LB plate of Amp100ug / ml+Km100 ug / ml, and place them in 100ml TB medium (Terrific Broth): 12 g / L tryptone (Tryptone), 24 g / L Yeast extract, 9.4 g / L K 2 HPO 4 and 2.2 g / L KH 2 PO 4 (pH6.8), cultivated overnight. The culture was collected by centrifugation, suspended in 20ml TB, and transferred to a 1L fermenter (Bioreactor, BIOSTAT Bplus Sartoris BBI system German product). The fermenter medium is TB containing ampicillin (Amp) 100ug / ml+kanamycin (Km) 100ug / ml, the total volume is 600ml. The temperature is controlled at 37°C, the rotation speed is 1200rpm, and the mixed gas (oxygen:air 1:10 v / v) is introduced at a flow rate of 60ml / min, and the pH is automatically adjusted to 6.8 with 28% ammonia water and 4 mol / L HCl. Incubate for about 4 hours, when the culture OD 600 When it reaches 5, add IPTG to make the final c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com