Continuous refining separation device and method for coal gasification crude phenol

A separation device and coal gasification technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high energy consumption in the separation process, unstable detection and feedback of crude phenol raw materials, waste of resources, etc., to achieve good results Economic and social benefits, solving heat-sensitive and easy-to-decompose effects, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

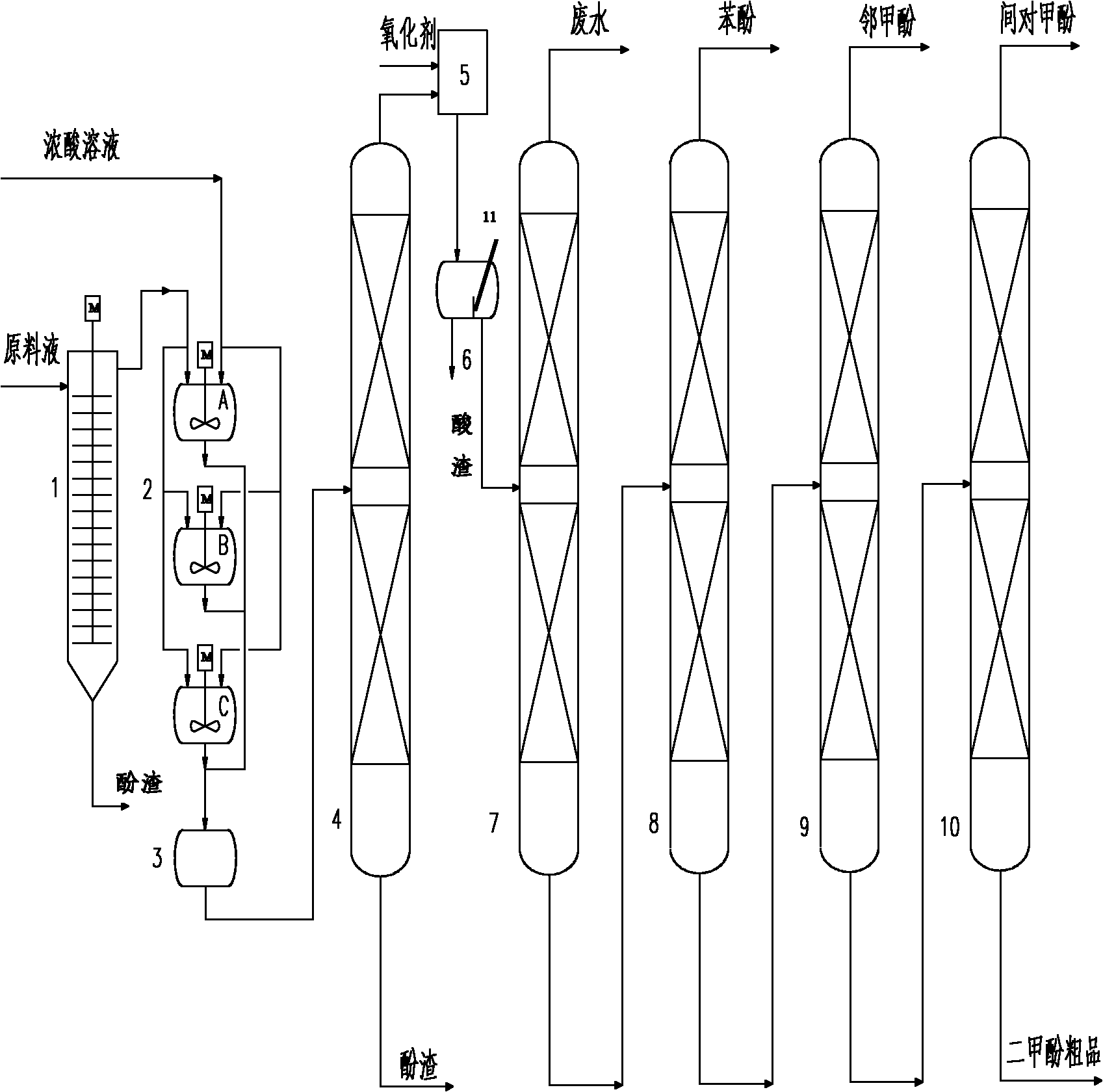

Embodiment 1

[0053] For the crude phenol raw material liquid recovered in the lignite gasification phenol-containing wastewater of a certain enterprise factory (the flow rate is 2500.0kg / h, the components are phenol 21.7%, o-cresol 6.6%, m-p-cresol 12.1%, water 14.4.0 %, xylenol 11.3%, heavy phenol 33.9%), first the crude phenol raw material liquid enters the wiped film evaporator, after the material enters the dephenol slag tower in the gas phase, the phenol residue is continuously discharged from the bottom, and the crude phenol raw material distilled from the top is mixed with Sulfuric acid solution (50.0wt%) enters the first acid adjustment tank group together, and the addition is 3.0% of the crude phenol raw material, then fully stirs in the first acid adjustment tank group at a speed of 60r / min, heats up to about 80°C, and the material enters Buffer tank, after being transported to the dephenol slag tower, the phenol slag is continuously discharged from the bottom of the tower, and th...

Embodiment 2

[0055] Aiming at the crude phenol raw material liquid recovered in the lignite pressurized gasification phenol-containing wastewater of a certain enterprise factory (the flow rate is 3750.0kg / h, the components are phenol 27.64%, o-cresol 7.92%, m-p-cresol 23.85%, water 7.63% %, xylenol 12.1%, heavy phenol 20.28%), first the crude phenol feedstock liquid enters the wiped film evaporator, after the material enters the dephenol residue tower in the gas phase, the phenol residue is continuously discharged from the bottom, and the crude phenol feedstock distilled from the top is mixed with Sulfuric acid solution (50.0wt%) enters the first acid adjustment tank group together, and the addition is 1.0% of the crude phenol raw material, then fully stirs in the first acid adjustment tank group at a speed of 60r / min, heats up to about 80°C, and the material enters Buffer tank, after being transported to the slagging tower, the phenol residue is continuously discharged from the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com