Preparation method and application of modified attapulgite clay

A kind of attapulgite clay, modified technology, applied in the direction of botanical equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of increased surface acidity, increased production costs, short storage period of pesticides, etc., and achieve stability Good, reduce pollution, prolong the effect of drug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

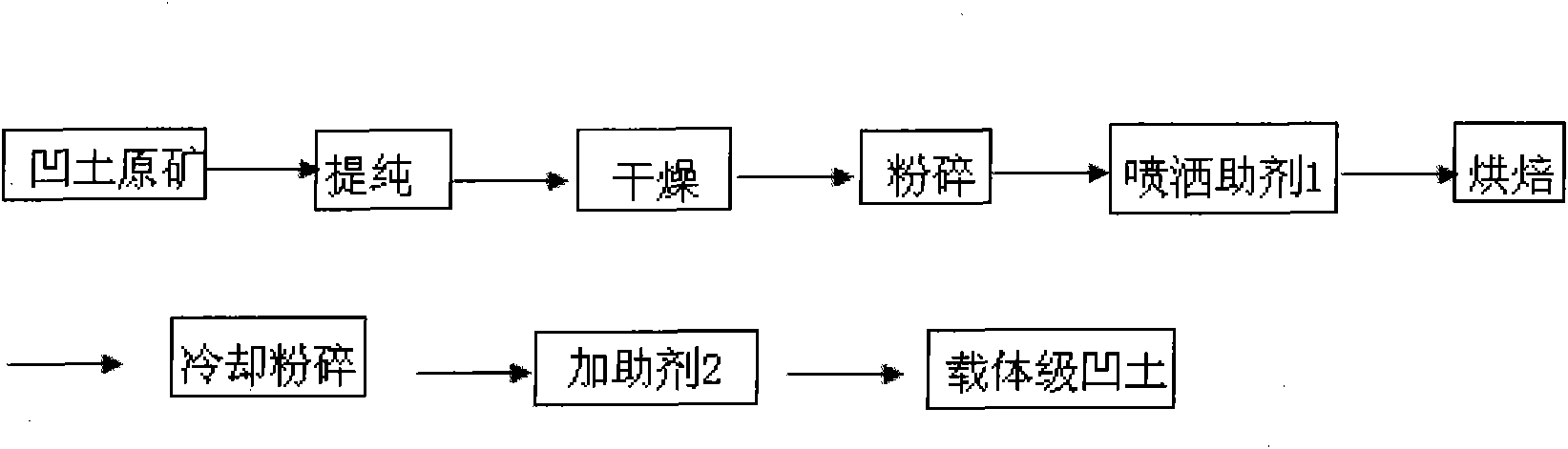

[0028] A preparation method of modified attapulgite clay, comprising the following steps:

[0029] (1) Purification Remove impurities such as opal, basalt and marble in attapulgite clay ore;

[0030] (2) Drying The purified attapulgite clay is dried, and the moisture content is required to be less than 5%;

[0031] (3) Pulverize the dried attapulgite clay;

[0032] (4) Spraying auxiliary agent 1 Spray the auxiliary agent 1 dissolved in water onto the sieved attapulgite clay particles, stir evenly, so that the auxiliary agent is fully coated on the surface of the attapulgite clay particles;

[0033] (5) Low-temperature baking Put the attapulgite clay that has been stirred evenly in step (4) into an oven for low-temperature baking, the temperature is controlled at 35-45°C, kept at a constant temperature for 3-4 hours, cooled and pulverized;

[0034] (6) Add additive 2 Add additive 2 to the attapulgite clay pulverized in step (5), and stir well.

[0035] When the step (3) is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com