Method of manufacturing semiconductor element metal gate stack

A metal gate and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of component performance change, p-type metal gate resistance increase, etc., to reduce mismatch and RC Delayed, negativity-increased effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

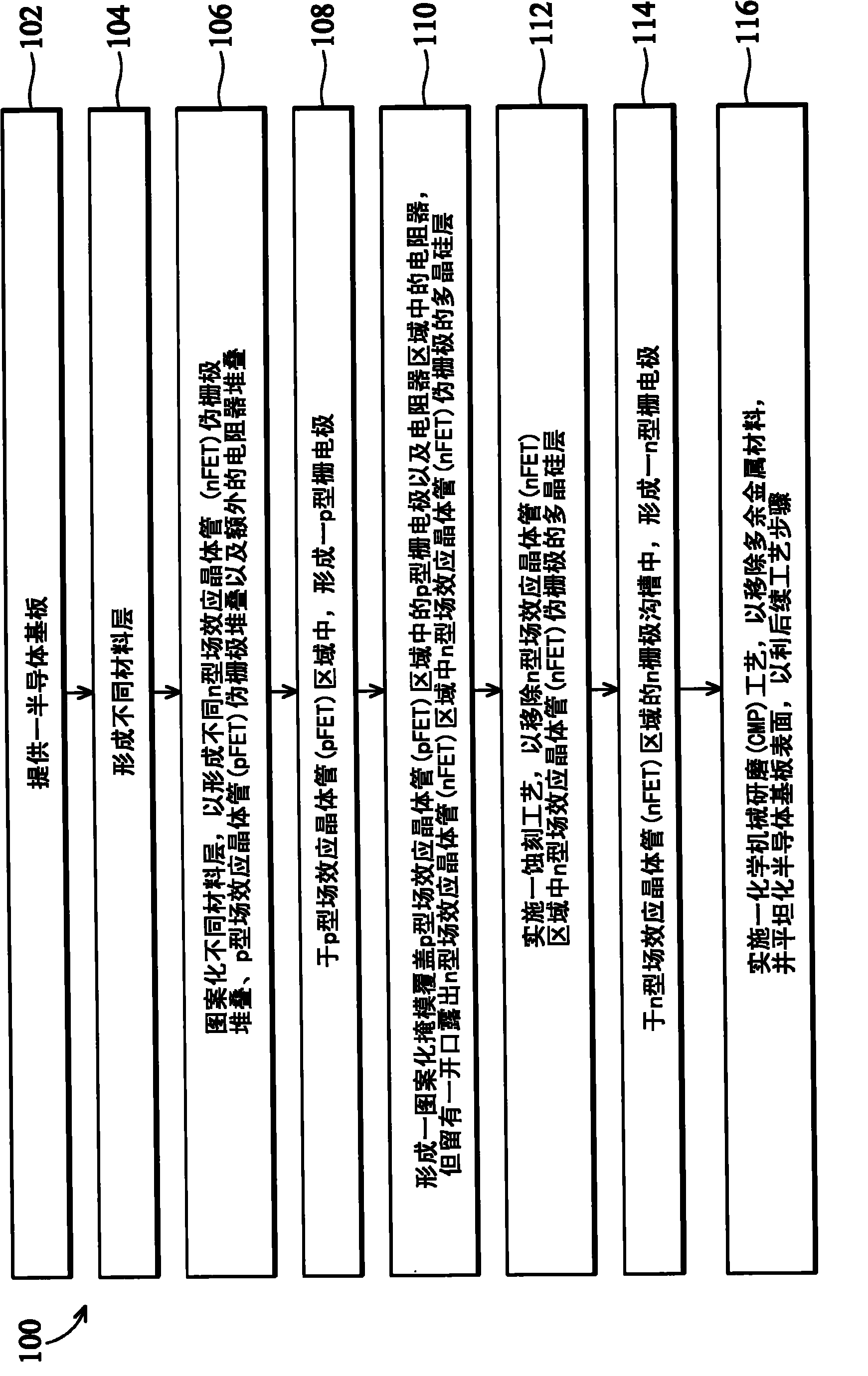

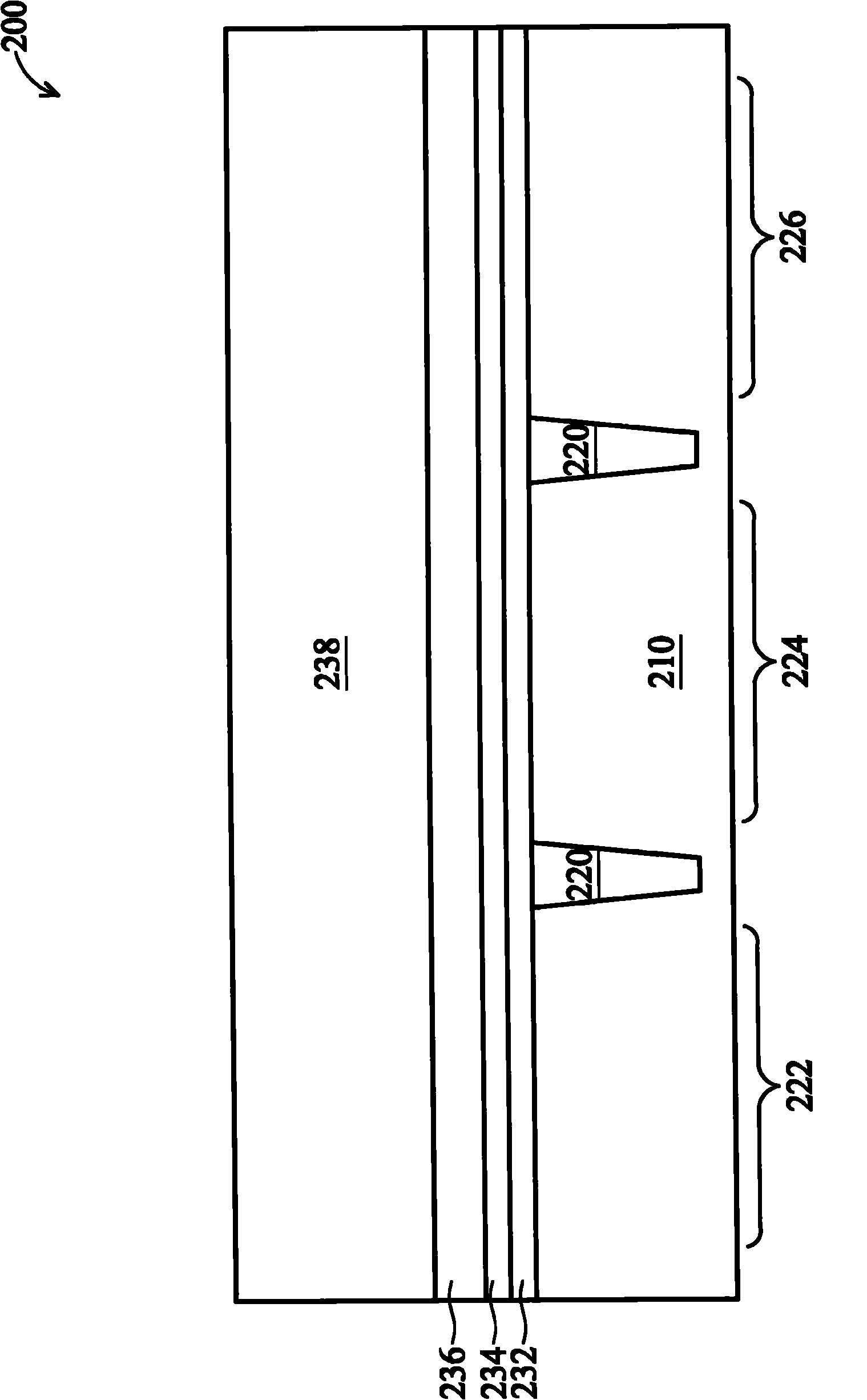

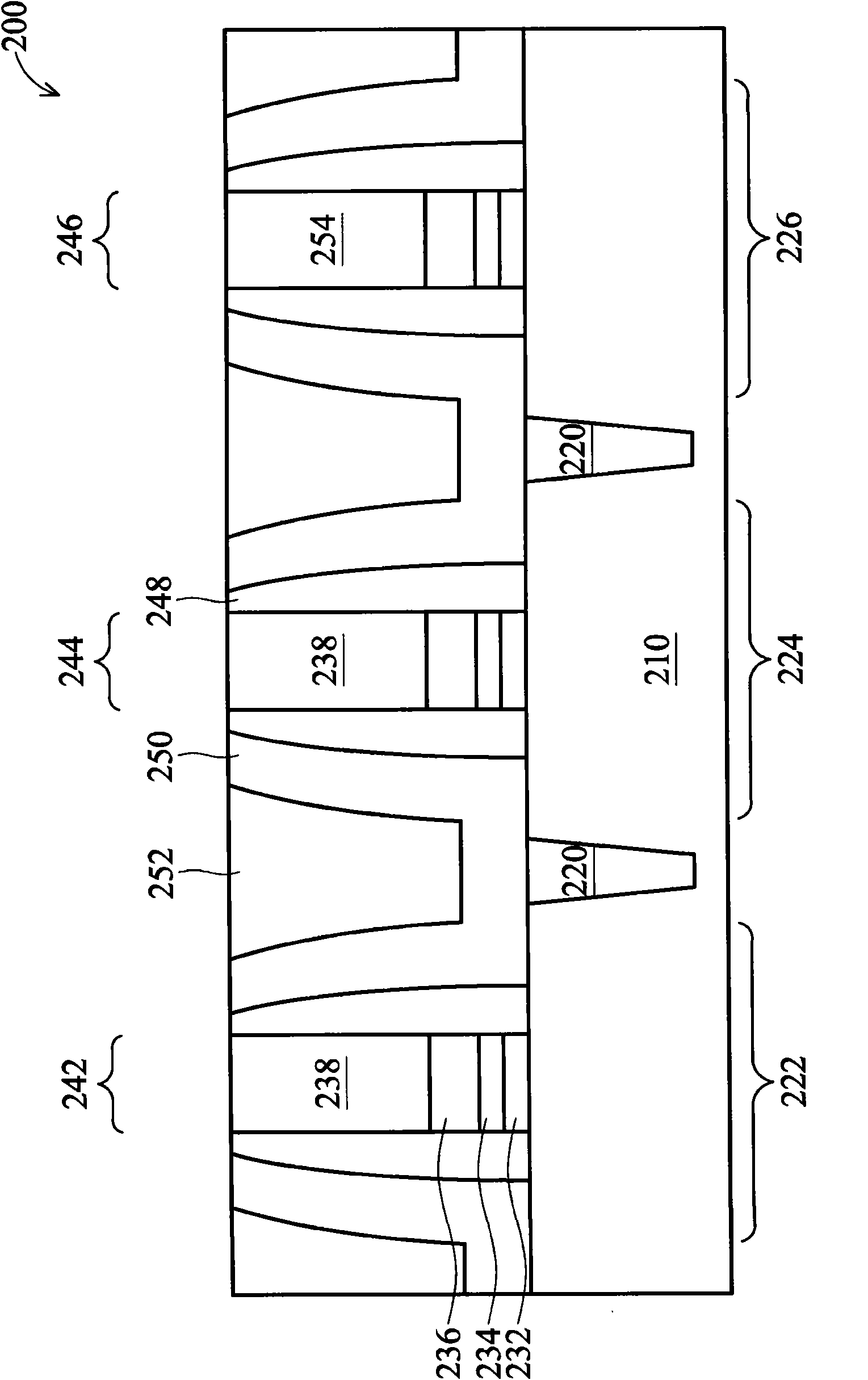

[0039] figure 1 A flowchart of an embodiment of a method 100 for fabricating a semiconductor device having a metal gate stack is disclosed in accordance with various aspects of the present invention. Figure 2 to Figure 7 In view of one or more embodiments of the present invention, schematic cross-sectional views of a semiconductor structure 200 at different process stages are disclosed. For a description of the semiconductor structure 200 and its manufacturing method 100, please refer to Figure 1 to Figure 7 .

[0040] see figure 1 , figure 2 The method 100 for manufacturing a semiconductor device of the present invention begins at step 102 , providing a semiconductor substrate 210 . The semiconductor substrate 210 includes silicon, and may optionally include germanium, silicon germanium or other suitable semiconductor materials. The semiconductor substrate 210 also includes various isolation structures 220 such as shallow trench isolations formed in the substrate to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com