Preparation process of light electronic packaging material

A technology for electronic packaging materials and preparation processes, which is applied to the improvement of process efficiency, circuits, electrical components, etc., can solve the problems of high cost and complicated preparation process, and achieve the effects of low cost, simple process and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

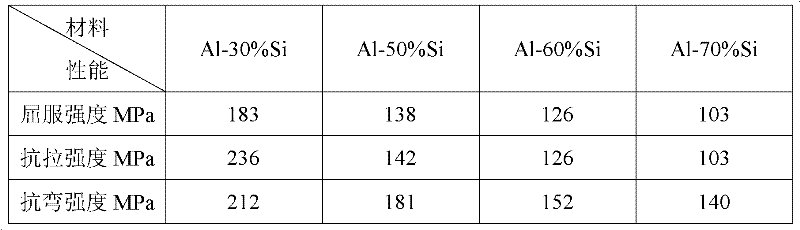

[0023] Industrial pure aluminum and high-purity silicon are smelted in a vacuum induction furnace at 830°C at a mass ratio of 7:3 (Al-30% Si), and evenly melted and cast into a metal mold with a diameter of 60mm to make aluminum-silicon self-consumption electricity Excellent, the length is 1m; the mass percentage is 21%Na 3 AlF 6 , 27% NaCl, and 52% KCl were mixed evenly, kept at 550°C for 6 hours as electroslag material, and kept in the oven until it was taken out before electroslag treatment to ensure dryness; put the consumable electrode rod into the electric The slag furnace is used for smelting, the working voltage of the electroslag furnace is 40V, the working current is 1.5kV, the arc starting block is pure aluminum block, and the arc starting slag material is CaF 2 During the smelting process, electroslag material is added as needed until the electroslag process is completed; after electroslag smelting, the aluminum-silicon ingot that is rapidly solidified by a water-...

Embodiment 2

[0025] Industrial pure aluminum and high-purity silicon are smelted in a vacuum induction furnace at 1040°C at a mass ratio of 1:1 (Al-50% Si), and evenly melted and cast into a metal mold with a diameter of 60mm to make aluminum-silicon self-consumption electricity Excellent, the length is 1m; the mass percentage is 23%Na 3 AlF 6 , 25% NaCl, and 52% KCl were mixed evenly, kept at 550°C for 7 hours as electroslag material, and kept in the oven until it was taken out before electroslag to ensure dryness; put the consumable electrode rod into electroslag The working voltage of the electroslag furnace is 40V, the working current is 2kV, the arc starting block is pure aluminum block, and the arc starting slag is CaF 2 During the smelting process, electroslag material is added as needed until the electroslag process is completed; after electroslag smelting, the aluminum-silicon ingot that is rapidly solidified by a water-cooled crystallizer is annealed at 340°C for 4 hours and the...

Embodiment 3

[0027] Industrial pure aluminum and high-purity silicon are smelted in a vacuum induction furnace at 1160°C at a mass ratio of 2:3 (Al-60% Si), and evenly melted and cast into a metal mold with a diameter of 60mm to make aluminum-silicon self-consumption electricity Excellent, the length is 1m; the mass percentage is 25%Na 3 AlF 6 , 27% NaCl, and 48% KCl were mixed evenly, kept at 550°C for 6 hours as electroslag material, and kept in the oven until it was taken out before electroslag to ensure dryness; put the consumable electrode rod into electroslag The working voltage of the electroslag furnace is 40V, the working current is 2.5kV, the arc starting block is pure aluminum block, and the arc starting slag is CaF 2 During the smelting process, the electroslag material is continuously added until the electroslag process is completed; after electroslag smelting, the aluminum-silicon ingot that is rapidly solidified by a water-cooled crystallizer is annealed at 360°C for 4.5 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com