High magnification polymer lithium ion power battery and preparation method thereof

A power battery and polymer technology, applied in secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., can solve problems such as explosion, unfavorable high-rate discharge of batteries, and low conductivity of lithium titanate, so as to improve voltage and The effect of outputting specific energy and improving high-current discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

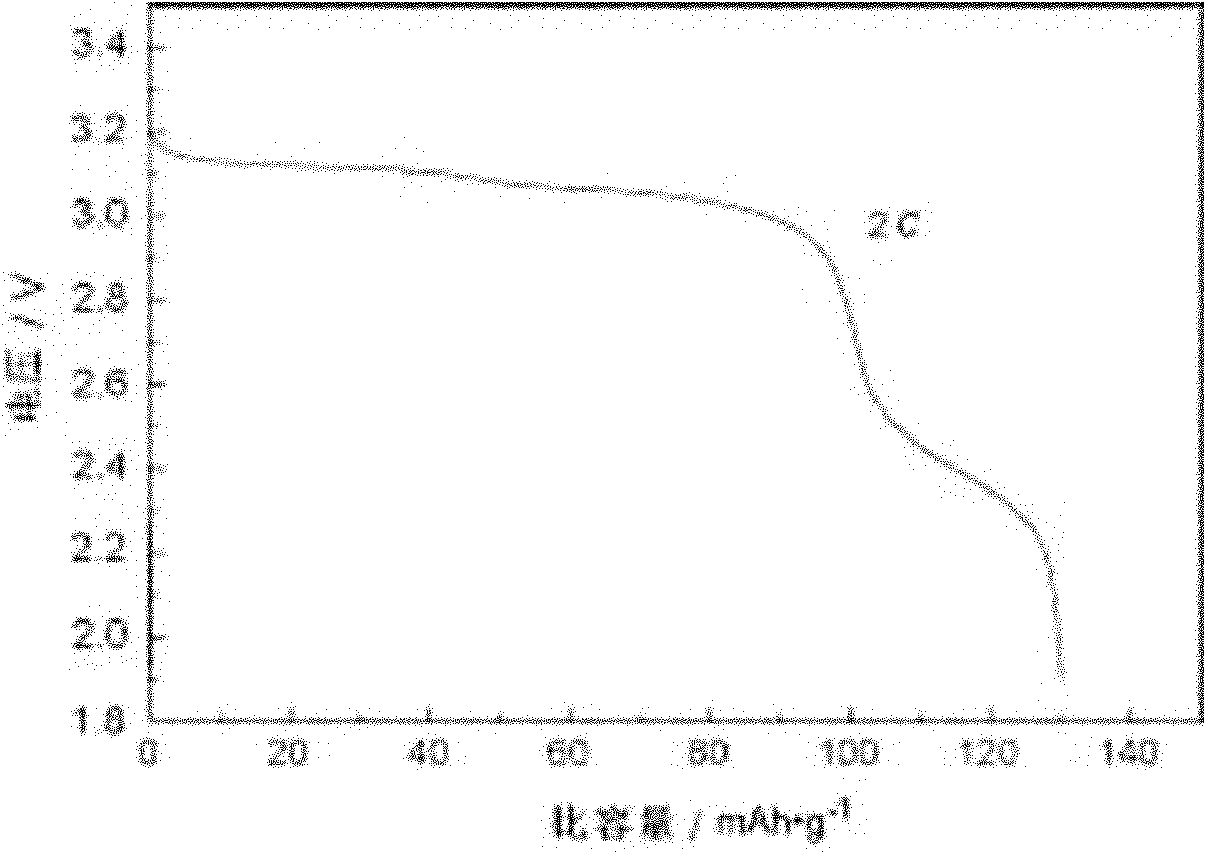

Examples

Embodiment 1

[0029] Positive electrode preparation: 92% of the surface is coated with AlPO 4 LiNi 0.5 mn 1.5 o 4 , 3% conductive carbon black, 1% nano-silver rods and 4% polyvinylidene fluoride (PVDF) are mixed in N-methylpyrrolidone (NMP) to form a slurry, evenly coated on the aluminum current collector, and finally 105 ° C Dried and compacted, cut into a size of 240*160mm to obtain the positive electrode.

[0030] Negative electrode preparation: 92% of lithium titanate (purchased from Shenzhen Beiterui New Energy Materials Co., Ltd., whose surface is coated with cracked carbon, wherein carbon: lithium titanate = 3: 97, but not limited to carbon: lithium titanate = The ratio of 3:97 can be carbon: lithium titanate = 1~8:92~99), 4% conductive carbon black and 4% polyvinylidene fluoride (PVDF) mixed in N-methylpyrrolidone (NMP) Slurry was formed, evenly coated on the copper foil, and finally dried and compacted at 105°C, and cut into a size of 242*163mm to obtain the negative electrode....

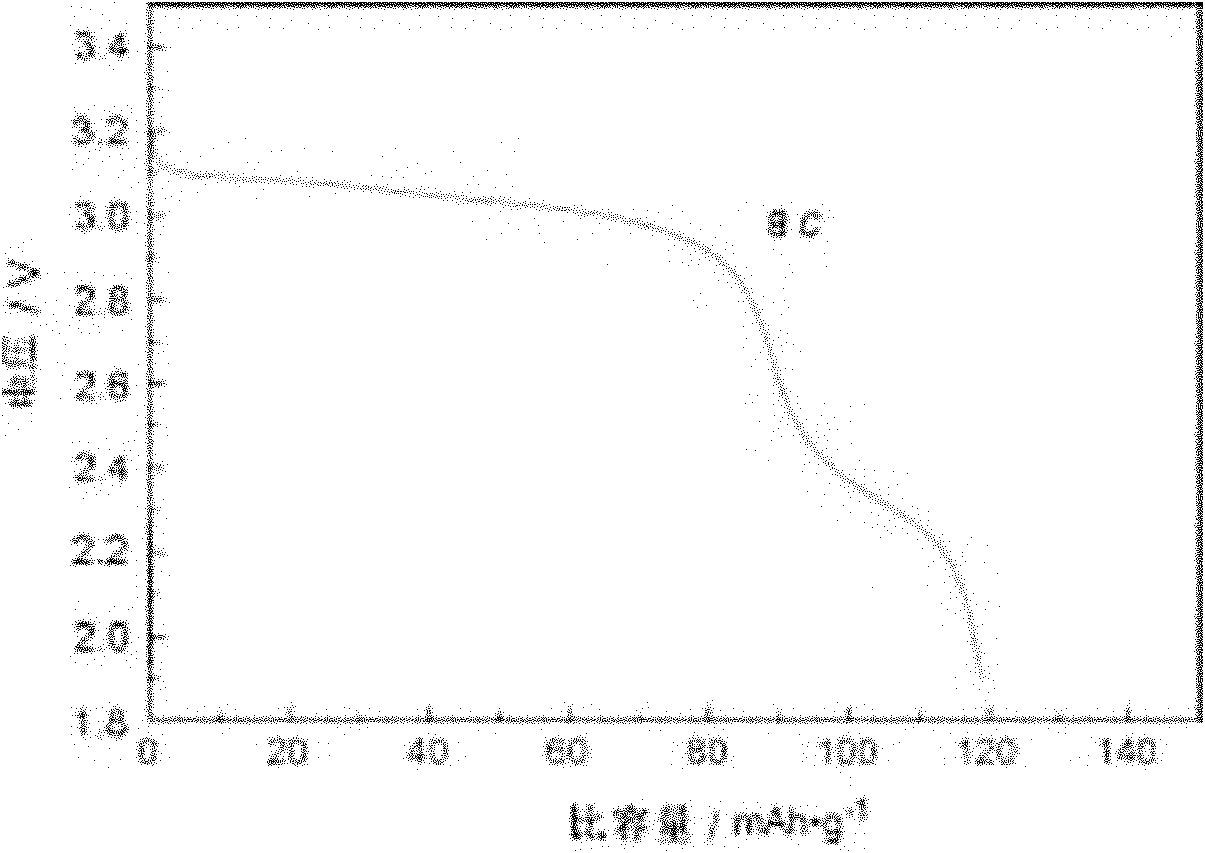

Embodiment 2

[0035] Positive electrode preparation: 90% of the surface is covered with AlPO 4 LiNi 0.5 mn 1.5 o 4, 3% conductive carbon black, 3% carbon nanotubes and 4% polyvinylidene fluoride (PVDF) are mixed in N-methylpyrrolidone (NMP) to form a slurry, evenly coated on the aluminum current collector, and finally 105 ° C Dried and compacted, cut into a size of 240*160mm to obtain the positive electrode.

[0036] Negative electrode preparation: 90% of the surface is coated with cracked carbon lithium titanate (purchased from Shenzhen Beiterui New Energy Materials Co., Ltd., wherein carbon: lithium titanate = 3: 97, but not limited to carbon: lithium titanate = The ratio of 3:97 can be carbon: lithium titanate = 1~8:92~99), 6% conductive carbon black and 4% polyvinylidene fluoride (PVDF) mixed in N-methylpyrrolidone (NMP) Slurry was formed, evenly coated on the copper foil, and finally dried and compacted at 105°C, and cut into a size of 242*163mm to obtain the negative electrode.

...

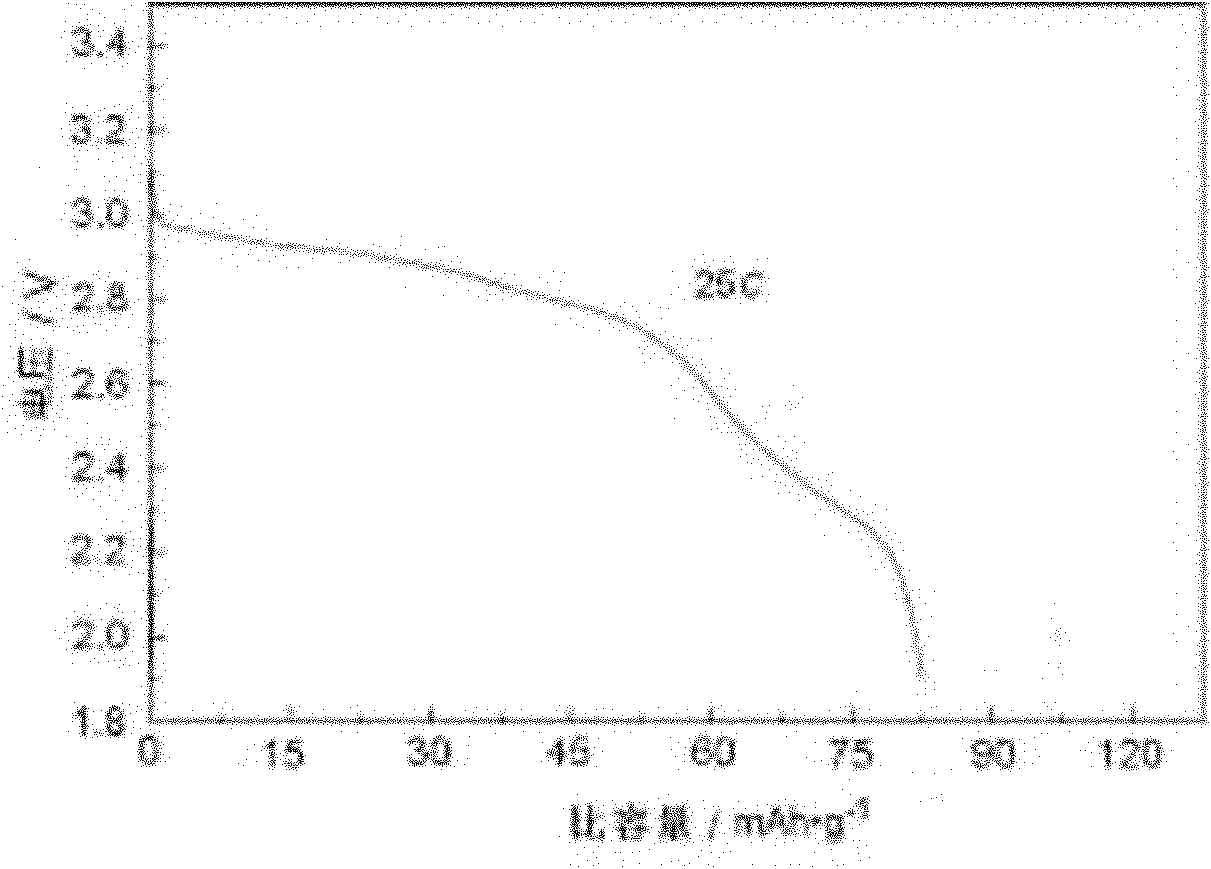

Embodiment 3

[0041] Positive electrode preparation: 88% of the surface is coated with AlPO 4 LiNi 0.5 mn 1.5 o 4 , 2% conductive carbon black, 2% nano-silver rods and 8% polyvinylidene fluoride (PVDF) are mixed in N-methylpyrrolidone (NMP) to form a slurry, evenly coated on the aluminum current collector, and finally 105 ° C Dried and compacted, cut into a size of 240*160mm to obtain the positive electrode.

[0042] Negative electrode preparation: Lithium titanate (purchased from Shenzhen Beiterui New Energy Materials Co., Ltd., with 88% of the surface coated with cracked carbon, wherein carbon: lithium titanate = 3: 97, but not limited to carbon: lithium titanate = The ratio of 3:97 can be carbon: lithium titanate = 1~8:92~99), 2% conductive carbon black and 10% polyvinylidene fluoride (PVDF) mixed in N-methylpyrrolidone (NMP) Slurry was formed, evenly coated on the copper foil, and finally dried and compacted at 105°C, and cut into a size of 242*163mm to obtain the negative electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com