Method and system for forming Cu-In-Ga-S-Se absorption layer and cadmium sulfide buffer layer in antivacuum way

A copper indium gallium sulfide selenide and absorber layer technology, which is applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of expensive manufacturing cost of equipment, many grain boundaries, and low material utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

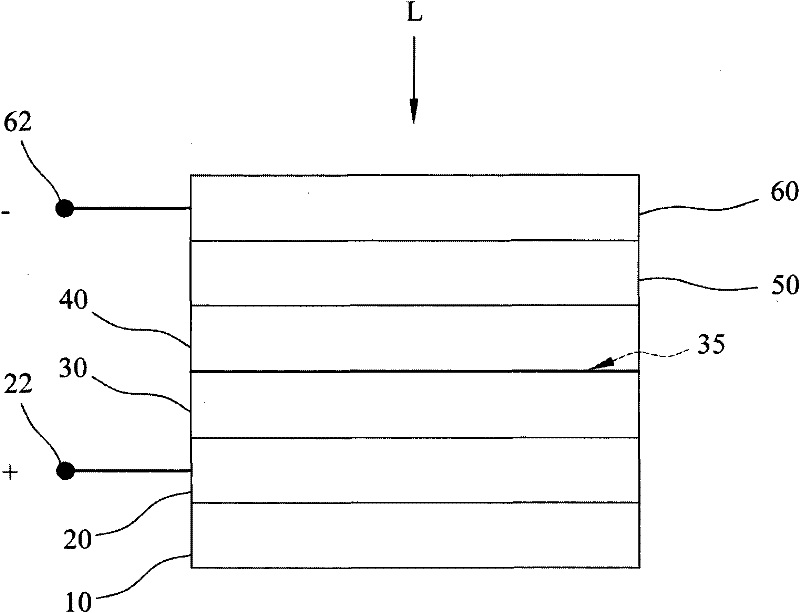

[0015] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

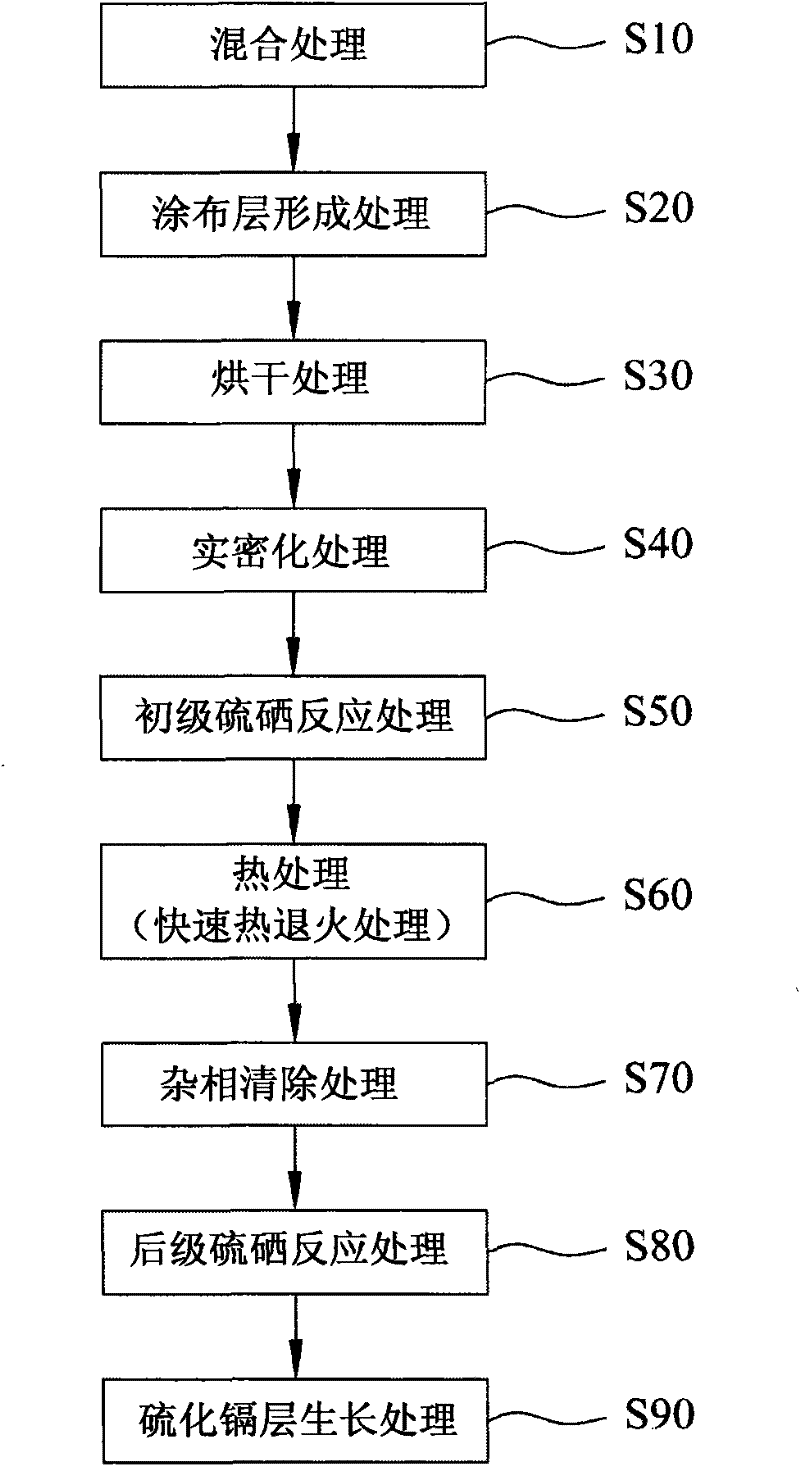

[0016] refer to figure 2 , a flowchart of the inventive method. Such as figure 2 As shown, the method of the present invention starts from step S10, and the mixing process is carried out under non-vacuum, including mixing copper indium gallium sulfide selenide powder, solvent and additives to form copper indium gallium sulfide selenide slurry, the copper indium gallium sulfide selenide powder The body can include copper indium alloy (CuIn), copper indium gallium compound (CuInGa), copper indium selenide (CuInSe), copper indium gallium selenide (CuInGaSe), copper indium sulfide (CuInS) and copper indium gallium sulfide (CuInGaS) powder The solvent may include at least one of alcohols and amines, and the additive may include at least one of dispersants, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com