Direct current glow plasma device and preparation method of diamond chip

A plasma and DC glow technology, applied in the field of plasma technology and material preparation, can solve the problems of increasing the collision frequency of electrons and neutral particles, increasing the plasma temperature, etc., to achieve stable high pressure and suppress arc discharge transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a kind of preparation method of diamond sheet, comprising:

[0050] Putting the substrate into a growth chamber of a DC glow plasma device, the background pressure of the growth chamber is below 1Pa;

[0051] Introduce H into the growth chamber 2 The mixed gas of , Ar and hydrocarbon is used to excite the plasma by pulse direct current, the pulse frequency is 0.1kHz-4kHz, the cathode temperature is 800°C-1600°C, and the chemical vapor deposition is carried out to obtain the diamond sheet.

[0052] According to the present invention, the duty cycle is preferably 50%-100%, more preferably 70%-95%, and most preferably 80%-90%. The volume ratio of argon to hydrogen is preferably 1-10:100, more preferably 2-9:100, and most preferably 3-8:100. The discharge voltage is preferably 500-1200V, more preferably 600-1100V, most preferably 700-1000V; the discharge current is preferably 5-25A, more preferably 7-22A, most preferably 8-20A. The gas...

Embodiment 1

[0059] Coat the surface of the silicon wafer with diamond powder;

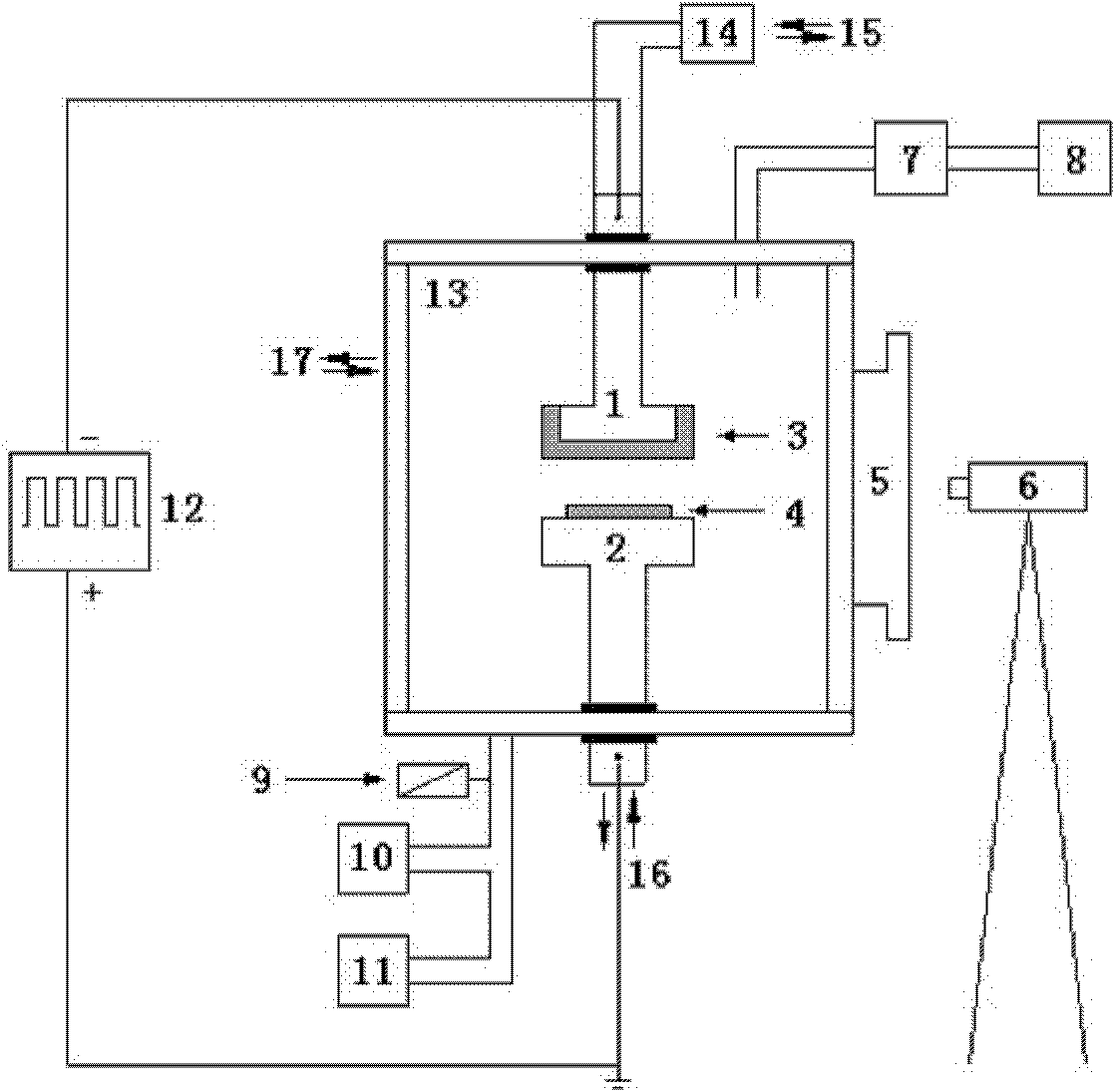

[0060] The silicon chip coated with diamond powder is placed in such as figure 1 On the anode base in the vacuum chamber of the DC glow plasma device shown, the vacuum chamber is pumped to 0.1Pa with a mechanical pump;

[0061] Fill the vacuum chamber with a mixed gas of hydrogen and argon, the ratio of argon to hydrogen is 1%, and discharge is performed under the condition of air pressure to 160 Torr, the discharge duty cycle is 80%, the discharge voltage is 1000V, and the discharge current is 18A, the pulse frequency is 2kHz, and the cathode temperature is 900°C-1100°C. Then feed methane gas accounting for 1% of the total flow rate, keep the pressure in the vacuum chamber constant, and carry out chemical vapor deposition to obtain diamond sheets.

[0062] Such as Figure 5 , Image 6 Shown is an optical microscope image of the diamond sheet prepared in this embodiment. The diamond sheet prepared in this ...

Embodiment 2

[0064] Coat the surface of the flat molybdenum disc with diamond powder;

[0065] The molybdenum sheet coated with diamond powder is placed as figure 1 On the anode base in the vacuum chamber of the DC glow plasma device shown, use a mechanical pump to pump the vacuum chamber until the background pressure is lower than 1Pa;

[0066] Fill the vacuum chamber with a mixed gas of hydrogen and argon, the ratio of argon to hydrogen is 4%, and discharge is carried out under the condition of air pressure to 200 Torr, the discharge duty ratio is 85%, and the discharge voltage is 1000V. The current is 18A, the pulse frequency is 2kHz, and the cathode temperature is 1100°C. Then feed alcohol vapor accounting for 3% of the total flow rate, keep the pressure in the vacuum chamber constant, and carry out chemical vapor deposition to obtain diamond sheets. The diamond sheet prepared in this embodiment has a diameter of 65 mm and a thickness of 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com