Method for preparing degradable polymer microspheres with controllable grain size

A technology for degrading polymers and polymers, applied in medical science, block delivery, prostheses, etc., can solve the problems of polymer micellar particles that are difficult to degrade and cannot be used in the body, and achieve good biocompatibility and biological The effect of degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

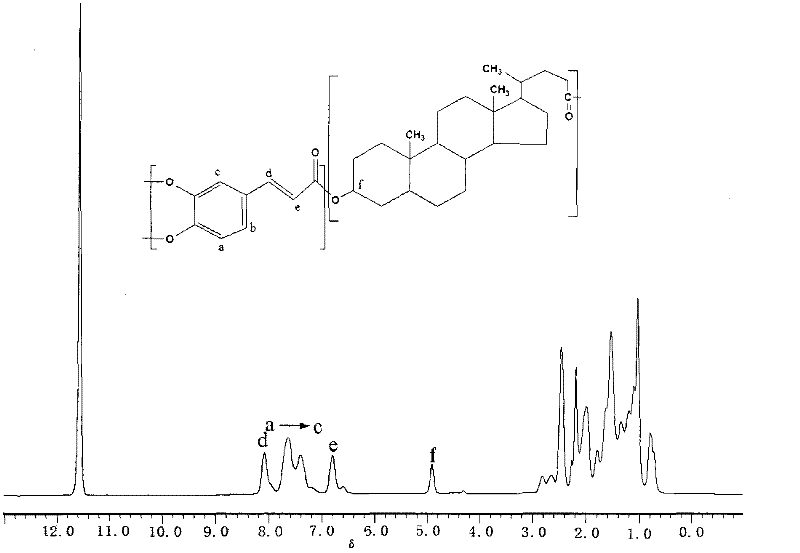

[0026] Weigh 5.264g (14mmol) of lithocholic acid, 1.08g (6mmol) of caffeic acid, 0.009g (0.1mmol) of sodium acetate, and 12ml of acetic anhydride, add them to a 250ml reactor, and heat up to 140°C at a stirring speed of 300r / min , reacted for 2 hours, and finally raised the temperature to 200° C., stirred and reacted at constant temperature for 6 hours, and the whole reaction was carried out under nitrogen protection and light-shielding conditions. Wash twice with deionized water, reprecipitate twice in ethanol, and then dry at constant temperature at 30°C to obtain a polymer product. The structure of the resulting polymer is:

[0027]

[0028] m=10-400, n=10-300, expressed as P(LCA-co-DHCA).

[0029] Dissolve the polymer in N,N-dimethylformamide (DMF) to form a 2mg / ml solution, take 5ml of the polymer solution, and -1 Slowly add 5ml of ultra-pure water to the polymer solution under stirring, stir at room temperature for 12 hours, add ultra-pure water 10 times of the solu...

Embodiment 2

[0031] Except 3.76g (10mmol) of lithocholic acid, 1.80g (10mmol) of caffeic acid, other is identical with embodiment 1.

Embodiment 3

[0033] Weigh 2.256g (6mmol) of lithocholic acid and 2.52g (14mmol) of caffeic acid, the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com