Preparation method of erbium ion-doped calcium fluoride laser transparent ceramic material

A technology of laser transparency and doped calcium fluoride, which is applied in the preparation of rare earth ion-doped calcium fluoride laser transparent ceramics and Er3+:CaF2 laser transparent ceramics, which can solve the problem of low transmittance and high experimental conditions. , complex process and other issues, to achieve high optical performance, low sintering temperature, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

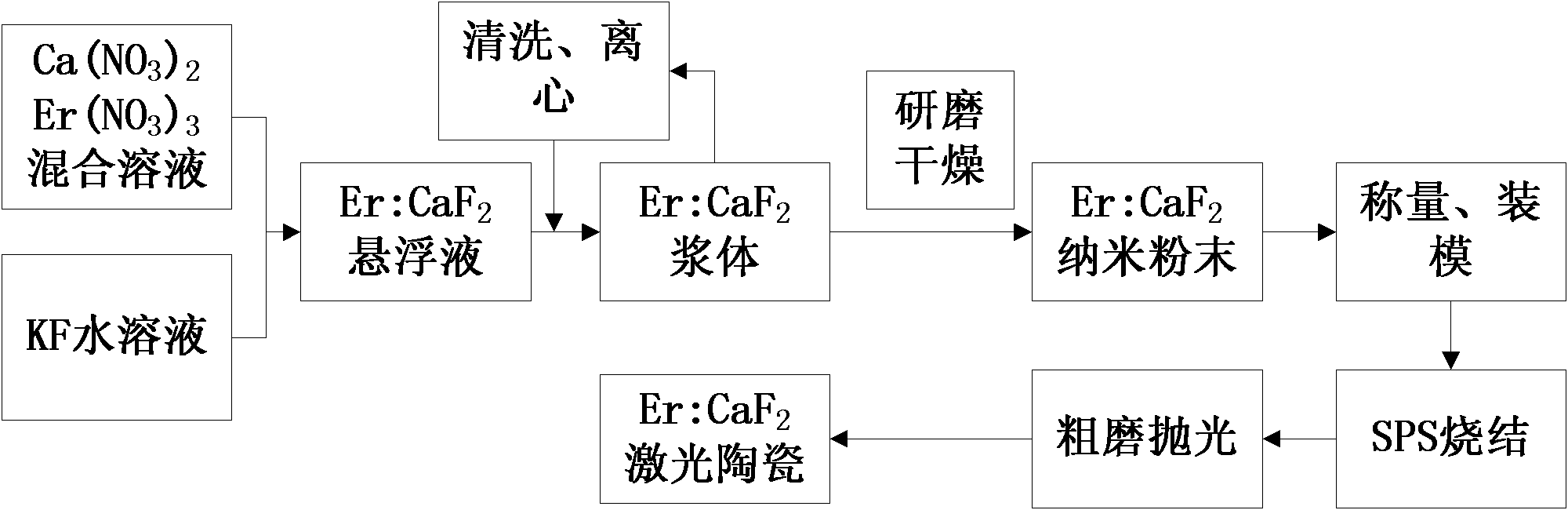

[0033] The preparation process is as figure 1 shown. According to the molar ratio of calcium ions and erbium ions in the sintered powder, n(Ca 2+ ):n(Er 3+ )=99.0:1.0 The ratio configuration concentration is 2M Ca(NO 3 ) 2 and Er(NO 3 ) 3 The mixed solution, and the KF solution with the same volume concentration of 4.02M; using the direct chemical co-precipitation method, the Ca(NO 3 ) 2 and Er(NO 3 ) 3 The mixed solution is slowly poured into the KF solution, magnetically stirred evenly, and the stirring rate is 500rpm to obtain a suspension of erbium ion-doped calcium fluoride nanopowder, and then after standing for 40 hours, alcohol cleaning, centrifugal separation, and vacuum drying at 80°C, etc. Steps to prepare 1mol% Er with an average grain size of 20nm 3+ :CaF 2 Nano powder. Put the powder into a graphite mold and sinter in a spark plasma sintering device with a heating rate of 10°C / min, a temperature of 600°C for 20 minutes, a pressure of 30MPa, and a vac...

Embodiment 2

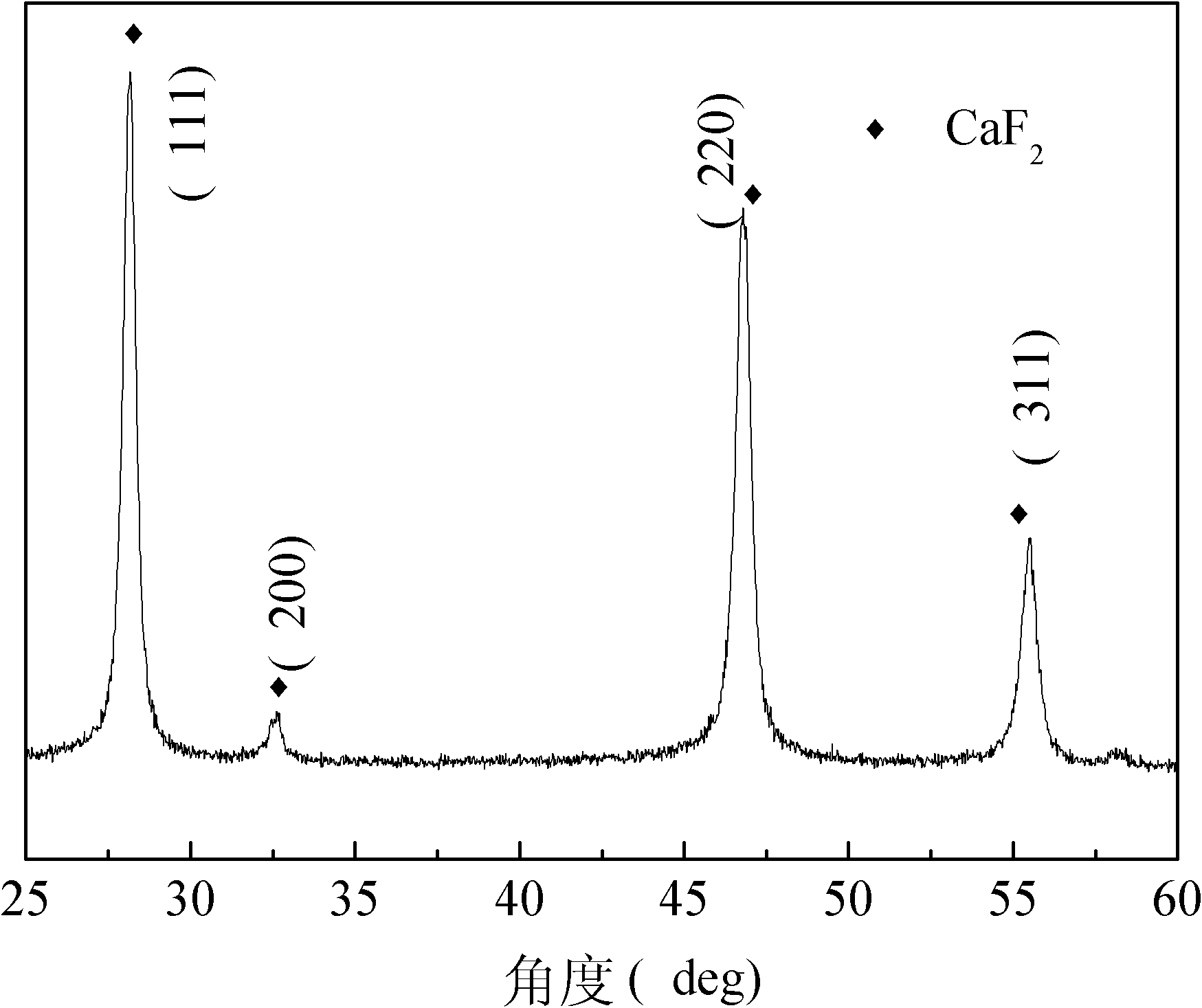

[0036] The preparation process is as figure 1 shown. According to the molar ratio of calcium ions and erbium ions in the sintered powder, n(Ca 2+ ):n(Er 3+ )=95.0:5.0 ratio configuration concentration of 2M Ca(NO 3 ) 2 and Er(NO 3 ) 3 The mixed solution, and the KF solution with the same volume concentration of 4.1M; using the direct chemical co-precipitation method, the Ca(NO 3 ) 2 and Er(NO 3 ) 3 The mixed solution is slowly poured into the KF solution, magnetically stirred evenly, and the stirring rate is 500rpm to obtain a suspension of erbium ion-doped calcium fluoride nanopowder, and then after standing for 40 hours, alcohol cleaning, centrifugal separation, and vacuum drying at 80°C, etc. Steps to prepare 5mol% Er with an average grain size of 18nm 3+ :CaF 2 Nanopowders, see figure 2 , is 5mol% Er 3+ :CaF 2 XRD patterns of nanopowders. Put the powder into a graphite mold and sinter in a spark plasma sintering device with a heating rate of 10°C / min, a te...

Embodiment 3

[0039] The preparation process is as figure 1 shown. According to the molar ratio of calcium ions and erbium ions in the sintered powder, n(Ca 2+ ):n(Er 3+ )=93.0:7.0 The ratio configuration concentration is 2M Ca(NO 3 ) 2 and Er(NO 3 ) 3 The mixed solution, and the KF solution with the same volume concentration of 4.14M; using the direct chemical co-precipitation method, the Ca(NO 3 ) 2 and Er(NO 3 ) 3 The mixed solution is slowly poured into the KF solution, magnetically stirred evenly, and the stirring rate is 500rpm to obtain a suspension of erbium ion-doped calcium fluoride nanopowder, and then after standing for 40 hours, alcohol cleaning, centrifugal separation, and vacuum drying at 80°C, etc. step, prepared 7mol% Er with an average grain size of 17nm 3+ :CaF 2 Nano powder. Put the powder into a graphite mold and sinter in a spark plasma sintering device with a heating rate of 10°C / min, a temperature of 600°C for 20 minutes, a pressure of 30MPa, and a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com