Embedded stirring and rubbing slit welding method

A friction stir and embedded technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as unsustainable welding, slow heating/cooling rate, loss of mechanical stirring and mixing effect, etc., to achieve energy saving and cost reduction Advantages, convenient and simple operation, and the effect of low cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An example (taking the economical aluminum plate and steel plate as an example) is given below to illustrate how to implement embedded friction stir seam welding, and introduce the test results of the welded joint performance to prove the practicability and innovation of the present invention.

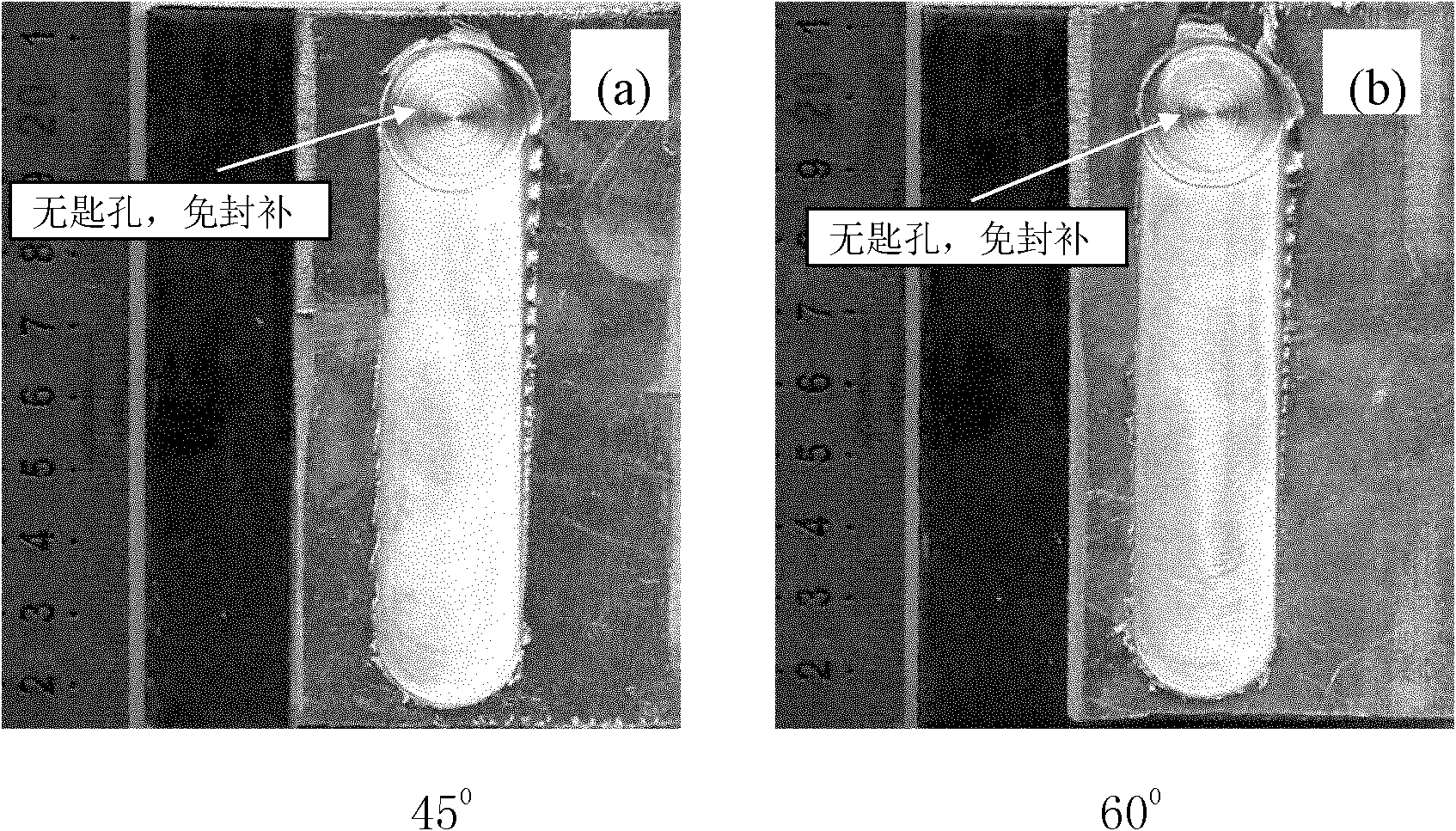

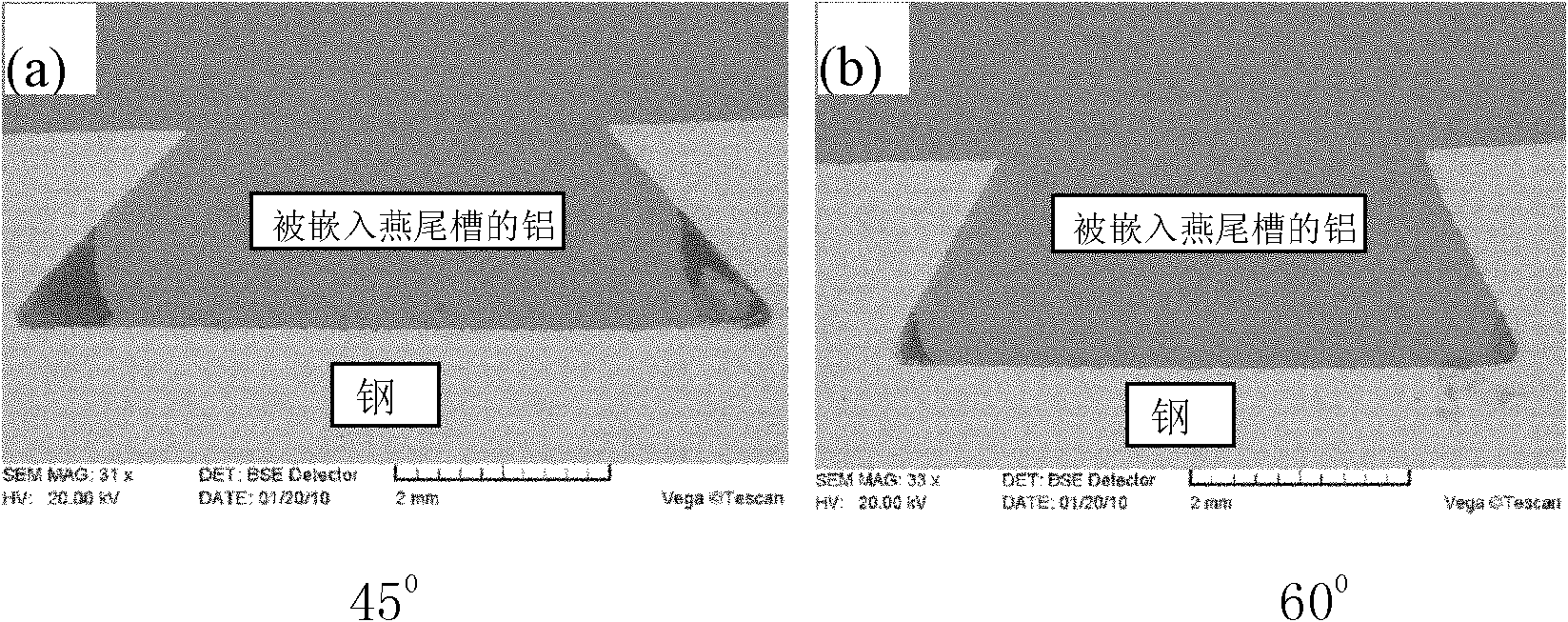

[0026] A commercially available pure aluminum plate with a thickness of 3 mm is selected as the first base material 1; a low-carbon steel plate with a thickness of 4 mm is used as the second base material 2 (the measured thickness is 3.84 mm). Before welding, the dovetail groove 4 is machined with EDM on the steel plate in advance, and the angle of the dovetail groove is 45° and 60°. The width of the upper notch is 4mm, and the depth of the groove is 2mm.

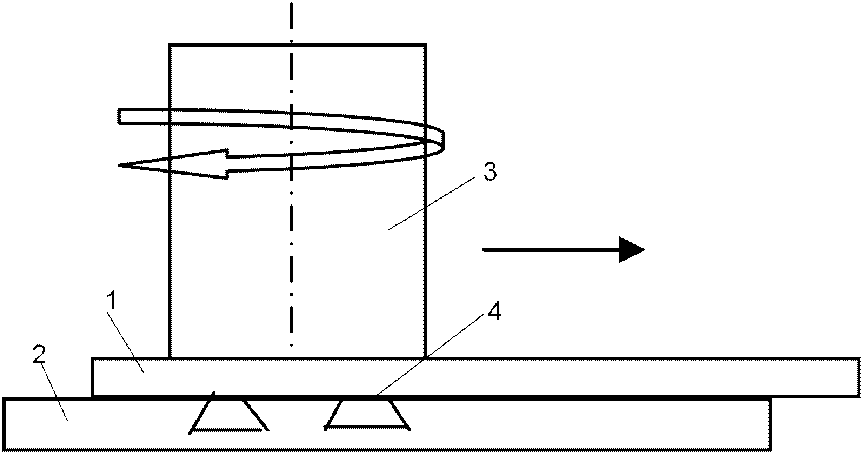

[0027] Assembled by lap joint, put the aluminum plate with low yield strength on the upper side, and put the steel plate with high yield strength on the lower side. Use ordinary milling machine or drilling machine for welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com