Preparation method of colloid of mono-dispersed silver nano particles and nano silver powder and conductive ink thereof

A technology of silver nanoparticles and conductive ink, applied in ink, household appliances, applications, etc., can solve problems such as reducing the performance of printed products, and achieve the effects of reducing preparation cost, high reaction conversion rate, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

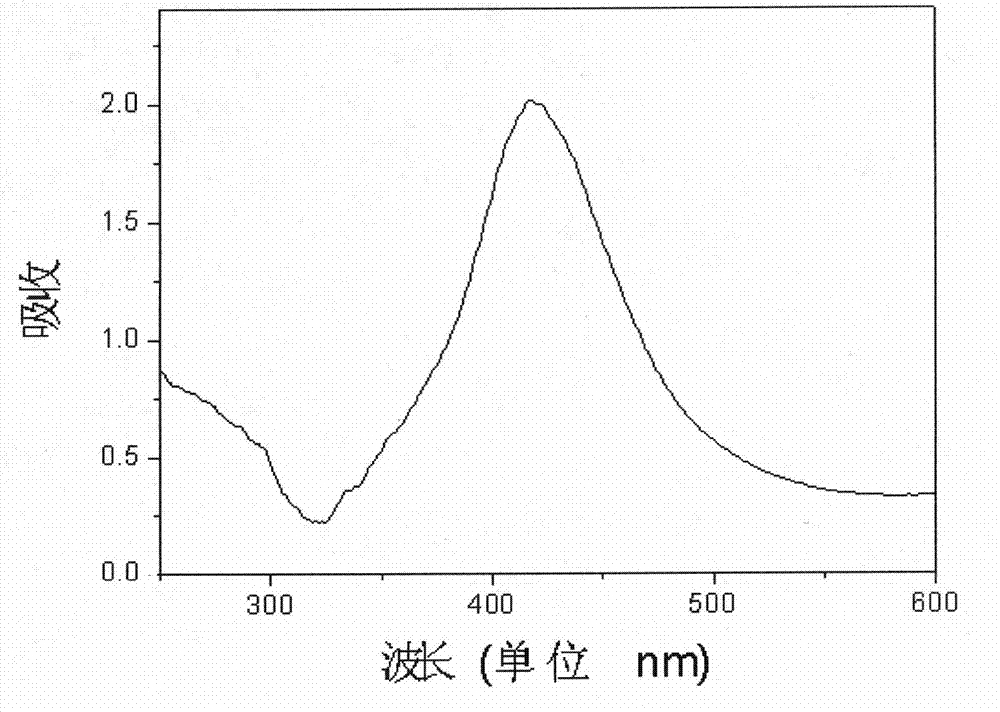

[0062] Dissolve 2g of silver nitrate in 15ml of water until fully dissolved; dissolve 4g of gum arabic in 30ml of water, stir until completely dissolved and add it to the above silver nitrate aqueous solution; The aforementioned structure, in which R1, R2, R3, R4, and R5 are all H) was added into 15ml of water, and fully stirred until completely dissolved. At room temperature and under stirring, add the prepared reducing agent acetylphenylhydrazine aqueous solution into the above-prepared mixed solution of silver nitrate and gum arabic in a constant flow and dropwise, and at the same time make up the amount of water to 70ml. Reaction stops after 30 minutes, obtains the colloid of the silver nanoparticle of monodisperse, and the transformation efficiency of silver nitrate is 79%; Obtain the ultraviolet-visible absorption spectrum of the colloid of the silver nanoparticle of monodisperse see figure 1 shown.

[0063] The scanning electron microscope model adopted is Hitachi S-55...

Embodiment 2

[0066] Dissolve 1g of silver acetate in 15ml of solvent toluene until fully dissolved; dissolve 6g of dispersant dodecylamine in 30ml of toluene, stir until completely dissolved and add it to the above silver salt solution; Acid dihydrazide (structural formula is: ) was added to 15ml of toluene, stirred thoroughly until completely dissolved. At room temperature and under stirring, the prepared reducing agent solution was added dropwise at a constant flow to the above-prepared mixed solution of silver acetate and dodecylamine, and the final solvent volume was controlled at 60 ml. At normal temperature, the reaction was stopped after 60 minutes to obtain a colloid of monodispersed silver nanoparticles, and the conversion rate of silver acetate was 71%.

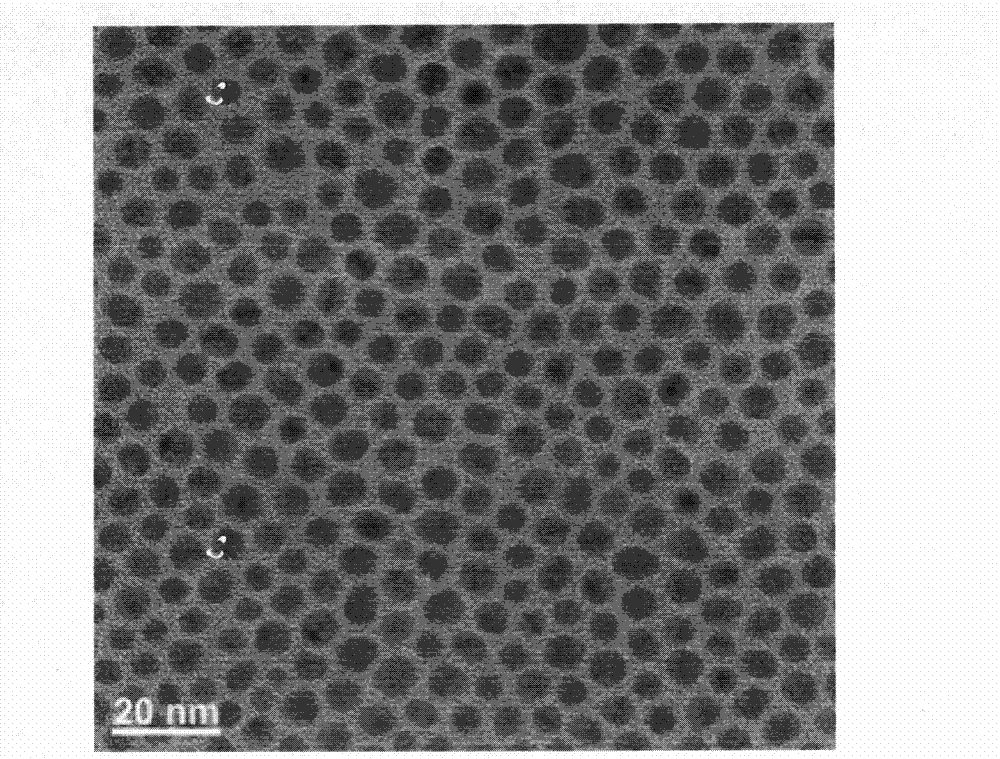

[0067]The transmission electron microscope model that adopts is Japan's JEM-2011, and the colloidal sample of the monodispersed silver nanoparticle that obtains is dropped on the copper grid that is attached with ultra-thin ca...

Embodiment 3

[0070] Dissolve 1g of silver nitrate in 15ml of water until fully dissolved; dissolve 3g of dispersant polyvinylamine in 20ml of water, stir until completely dissolved and add it to the above silver nitrate solution; then, add 1.5g of reducing agent oxalic acid di Hydrazide (the structural formula is: ) was added to 15ml of water and stirred thoroughly until completely dissolved. At the set temperature (30°C) while stirring, the prepared reducing agent oxalic acid dihydrazide aqueous solution was added dropwise at a constant flow to the above-mentioned mixed solution of silver nitrate and polyvinylamine, and the final amount of water was controlled at 50ml. At a temperature of 30° C., the reaction was stopped after 40 minutes to obtain a colloid of monodisperse silver nanoparticles, and the conversion rate of silver nitrate was 73%.

[0071] The model of the laser particle size analyzer used is (UK) Malvern Zetasizer Nano ZEN3600. The particle size distribution curve of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com