Expanding type steel structure fireproof and anticorrosion coating and preparation method thereof

A technology for anti-corrosion coatings and profiles, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problems of reduced material service life, loss of bottom material protection, poor compatibility, etc., to improve anti-corrosion performance, improve The effect of fire resistance and corrosion resistance, scrub resistance and scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

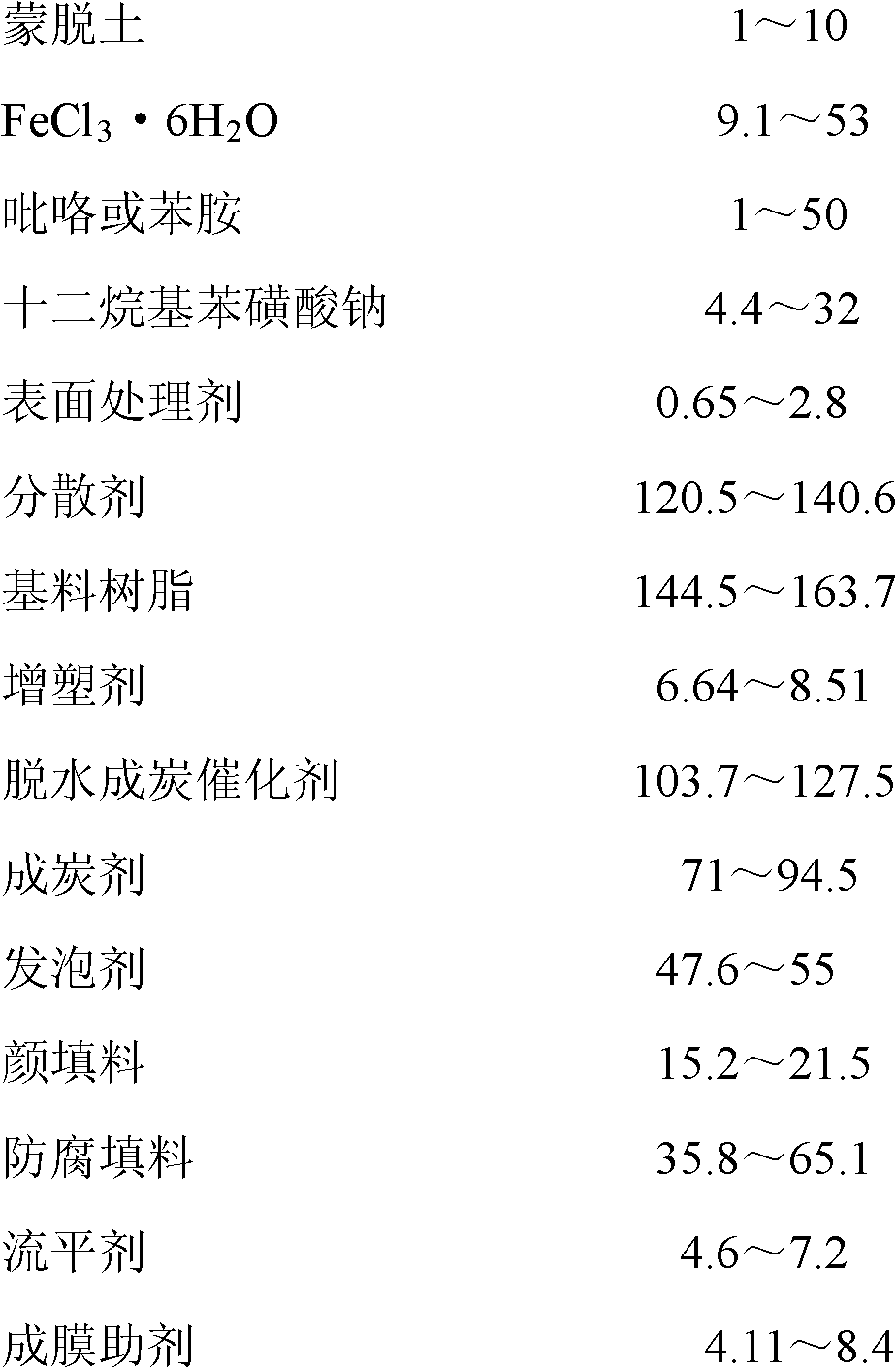

Method used

Image

Examples

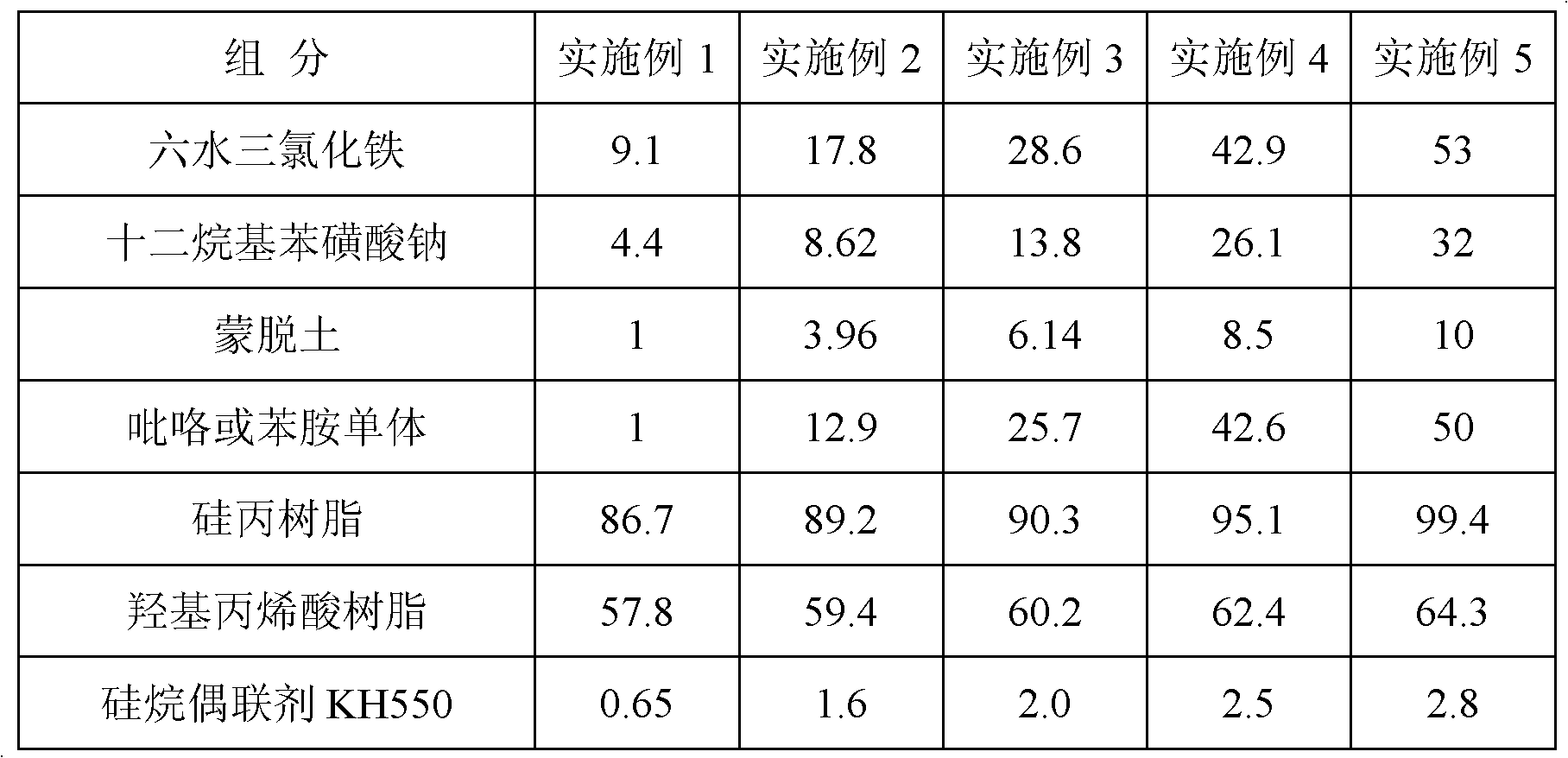

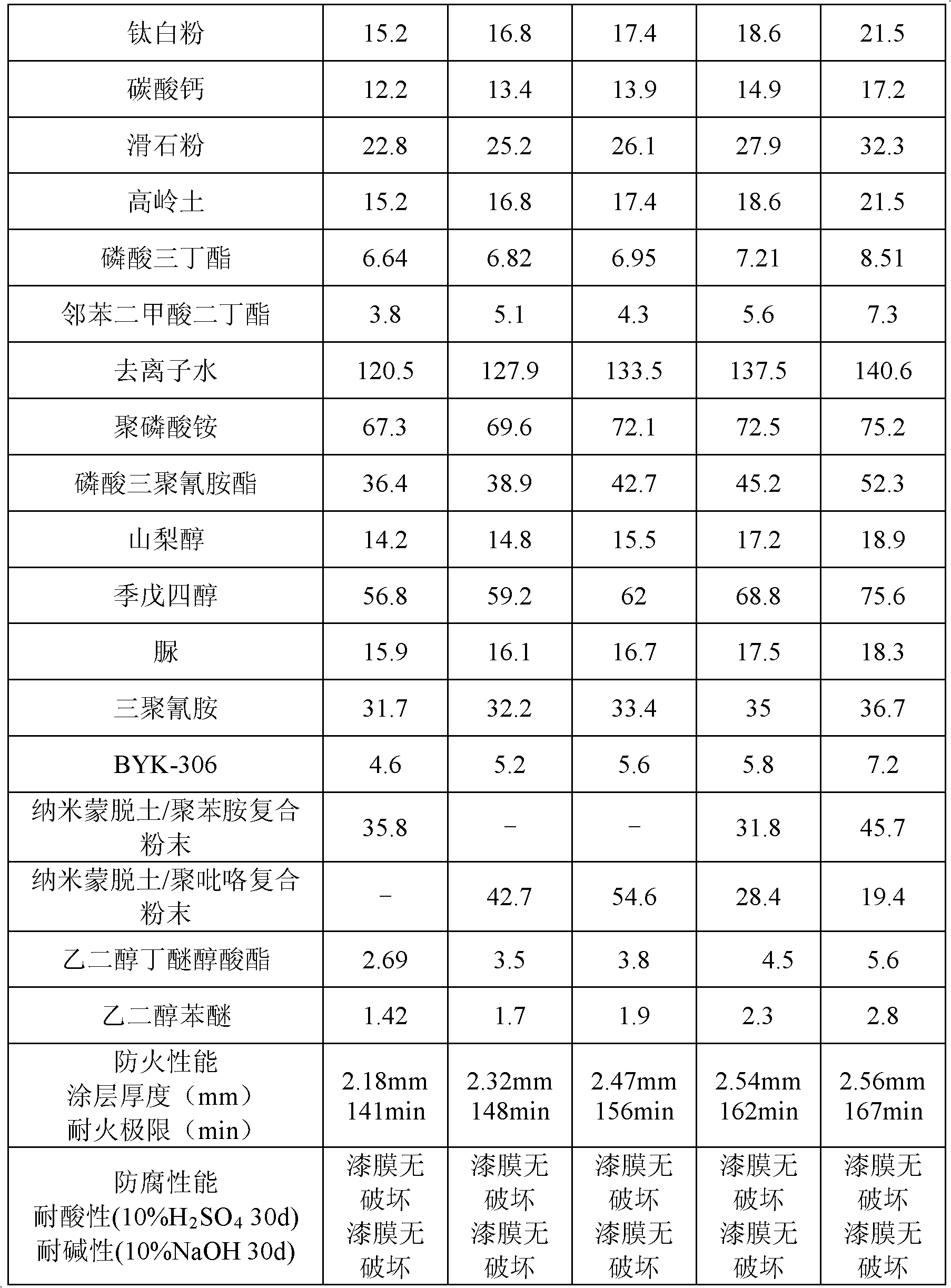

Embodiment 1~5

[0029] Step 1. Add 9.1g of ferric chloride hexahydrate, 4.4g of sodium dodecylbenzenesulfonate, and 1g of montmorillonite into 20mL of deionized water, stir evenly, inject 1mL of pyrrole monomer with a syringe, and the system turns black rapidly , Under the protection of nitrogen, react at room temperature for 12h. Ultrasonic dispersion is carried out in water, followed by centrifugation, and the obtained precipitate is repeatedly washed with deionized water until the filtrate is neutral. Vacuum drying at 60° C. for 24 hours, and grinding to obtain nano-montmorillonite / polypyrrole composite powder or nano-montmorillonite / polyaniline composite powder.

[0030] Step 2. Add titanium dioxide, calcium carbonate, talc, and kaolin into the high-speed disperser, gradually heat to 105°C, maintain the temperature for 10 minutes, stop heating, add silane coupling agent KH550, and disperse at high speed for 40 minutes.

[0031] Step 3. When the temperature is lower than 45°C, add hydroxy...

Embodiment 6

[0036] Example 6 (enlarged experiment, according to the conditions of implementation 1) 15.2kg of titanium dioxide, 12.2kg of light calcium, 22.8kg of talcum powder, and 15.2kg of kaolin were added to the high-speed disperser according to the proportioning ratio, and gradually heated to 105°C to maintain the temperature 10min, stop heating, add silane coupling agent, disperse at high speed for 40min, when the temperature is lower than 45℃, add 43.5kg modified acrylic resin, 86.7kg silicone acrylic resin, 120.5kg deionized water, 6.64kg tributyl phosphate in batches Ester, 67.3kg ammonium polyphosphate, 36.4kg melamine phosphate, 14.2kg sorbitol, 28.4kg pentaerythritol, 15.9kg urea, 31.7kg melamine, 4.6kg BYK-306, 35.8kg nano-montmorillonite / polyaniline composite powder, mixed for 120min After fully dissolving and dispersing, the material is introduced into a sand mill, ground, discharged, sieved and packaged. The properties of the obtained fireproof and anticorrosion coatings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com