Preparation method of composite anti-bacterium material

A composite antibacterial and ionic liquid technology, applied in the fields of botanical equipment and methods, fungicides, chemicals for biological control, etc. It takes a long time for bacteria to achieve the effect of easy industrial production, high temperature resistance and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

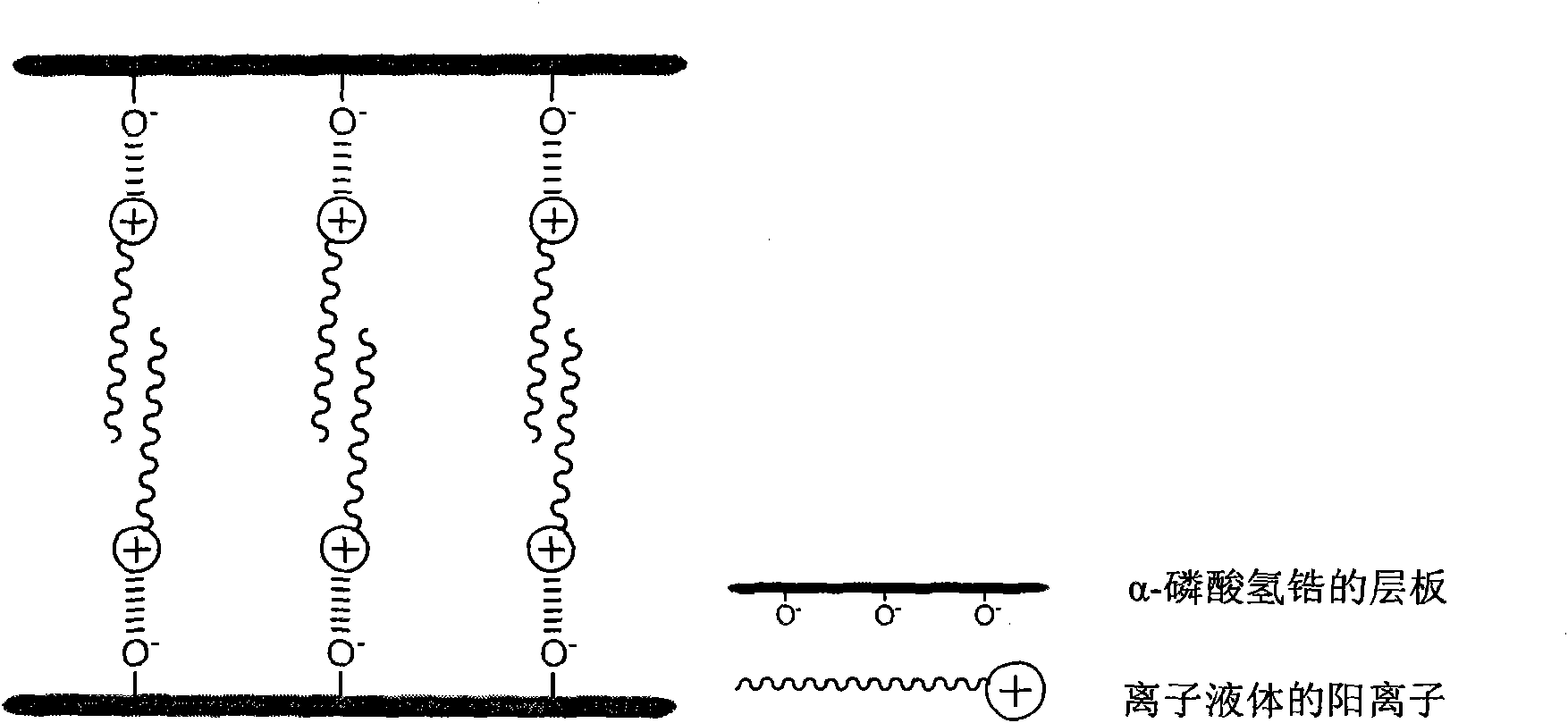

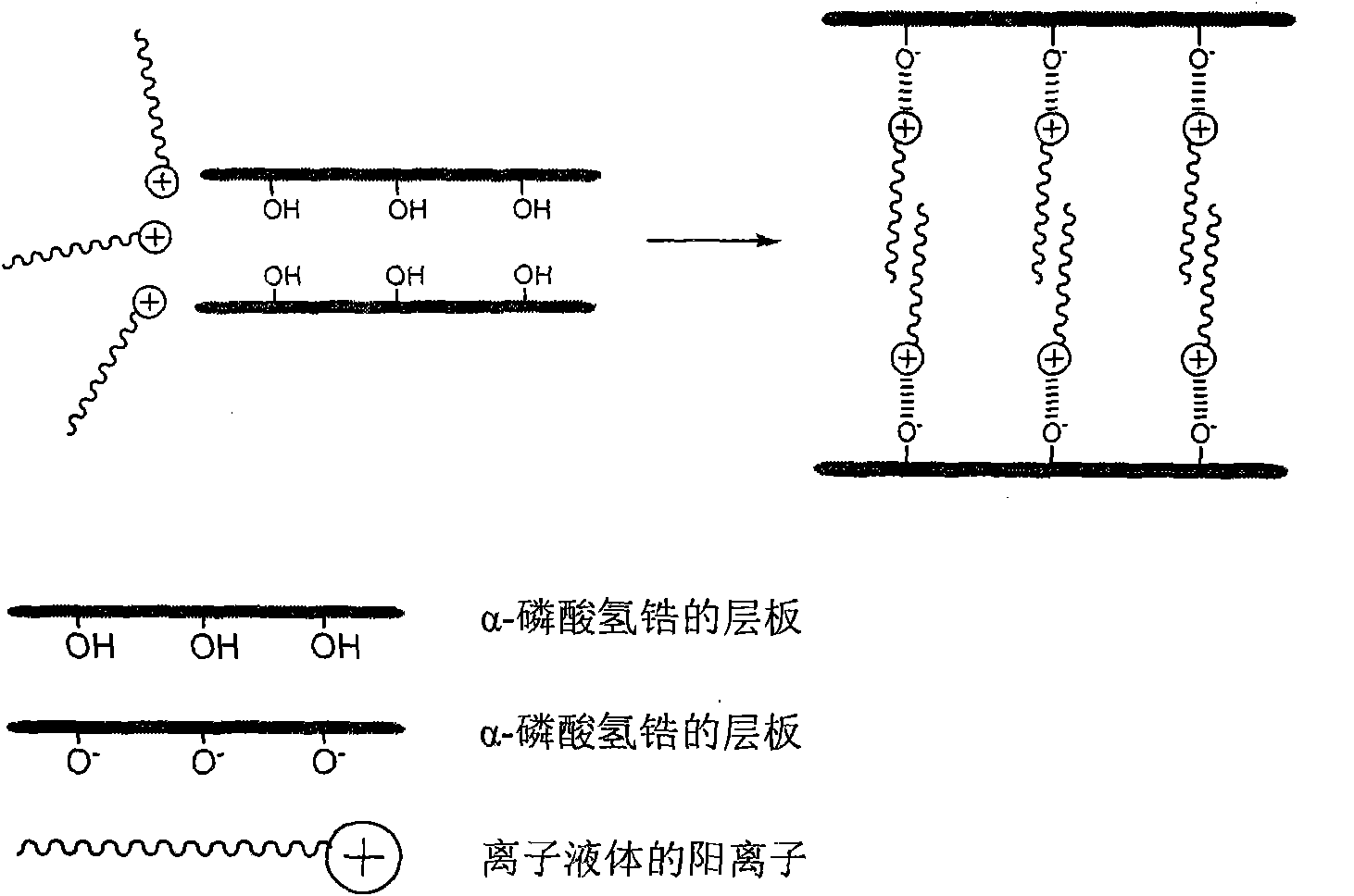

Method used

Image

Examples

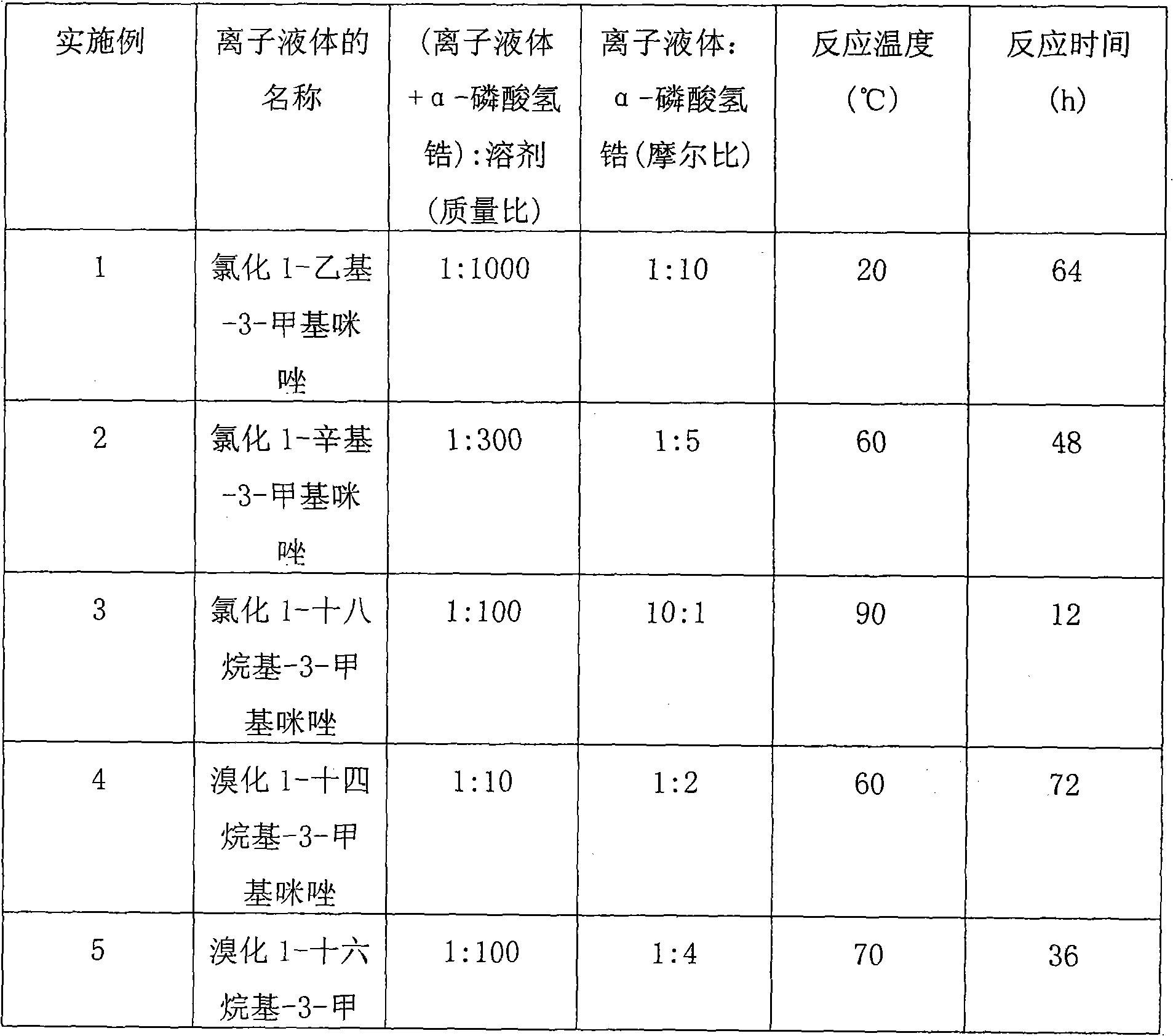

Embodiment 1

[0029] The present embodiment prepares chlorinated 1-alkyl-3-methylimidazolium ionic liquid intercalation α-zirconium hydrogen phosphate composite antibacterial material (Zr(C) through the preparation method of the present invention n MIM) (PO 4 ) 2 ), (C n MIM) represents 1-alkyl-3-methylimidazolium cation (n is a natural number from 1 to 20), and the specific steps are as follows:

[0030] 1) According to the chlorinated 1-ethyl-3-methylimidazolium ionic liquid (C 2 The molar ratio of MIMCl) and α-zirconium hydrogen phosphate is 1:10 for weighing.

[0031] The ionic liquid of this embodiment can also use pyridine ionic liquid, such as: 1-dodecylpyridinium chloride, or any of the following ionic liquids, such as imidazole ionic liquid, pyridinic ionic liquid, quaternary ammonium ionic liquid, quaternary Phosphorus ionic liquids, pyrrolidine ionic liquids, piperidine ionic liquids or marin ionic liquids are well known to those skilled in the art.

[0032]2) under normal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com