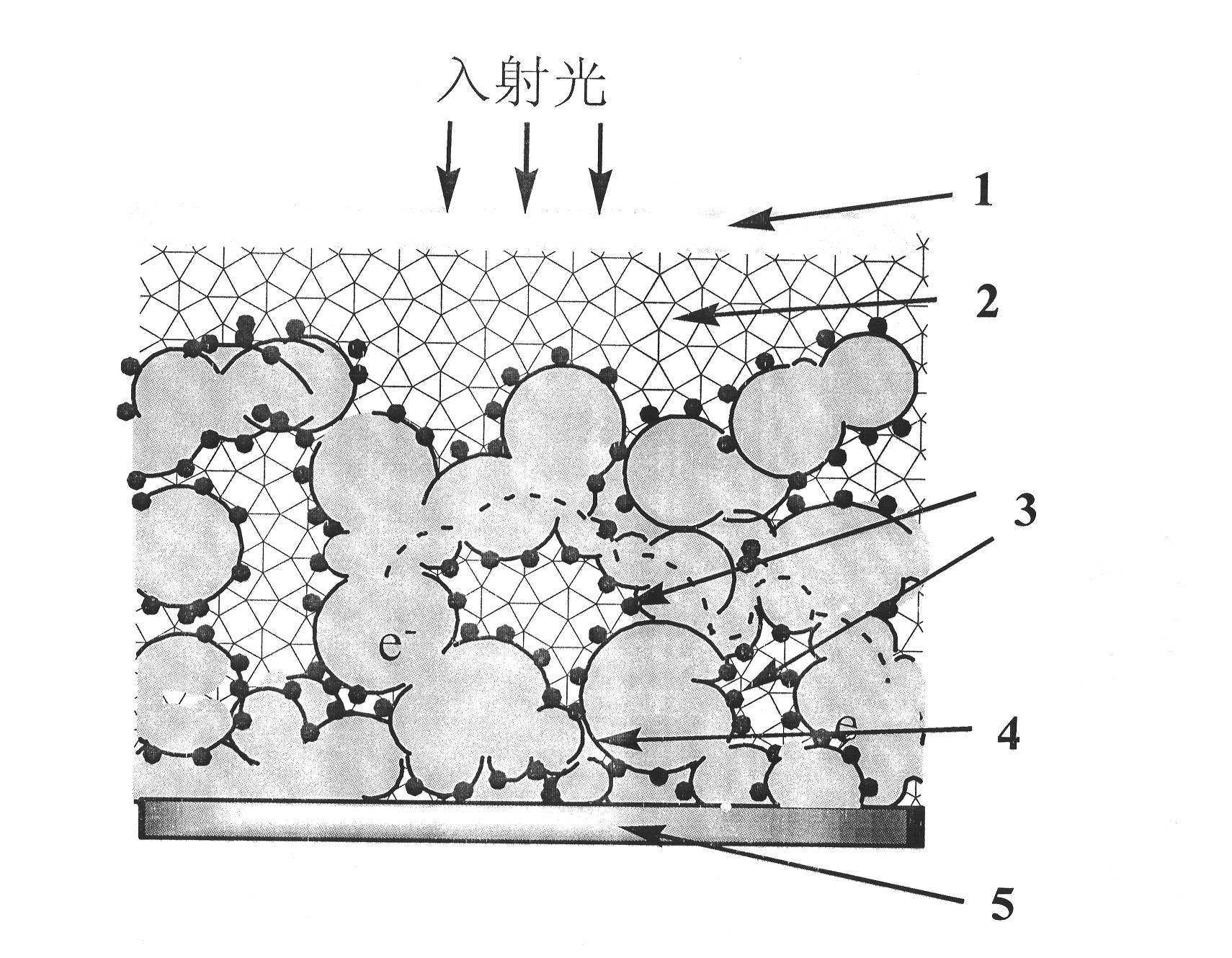

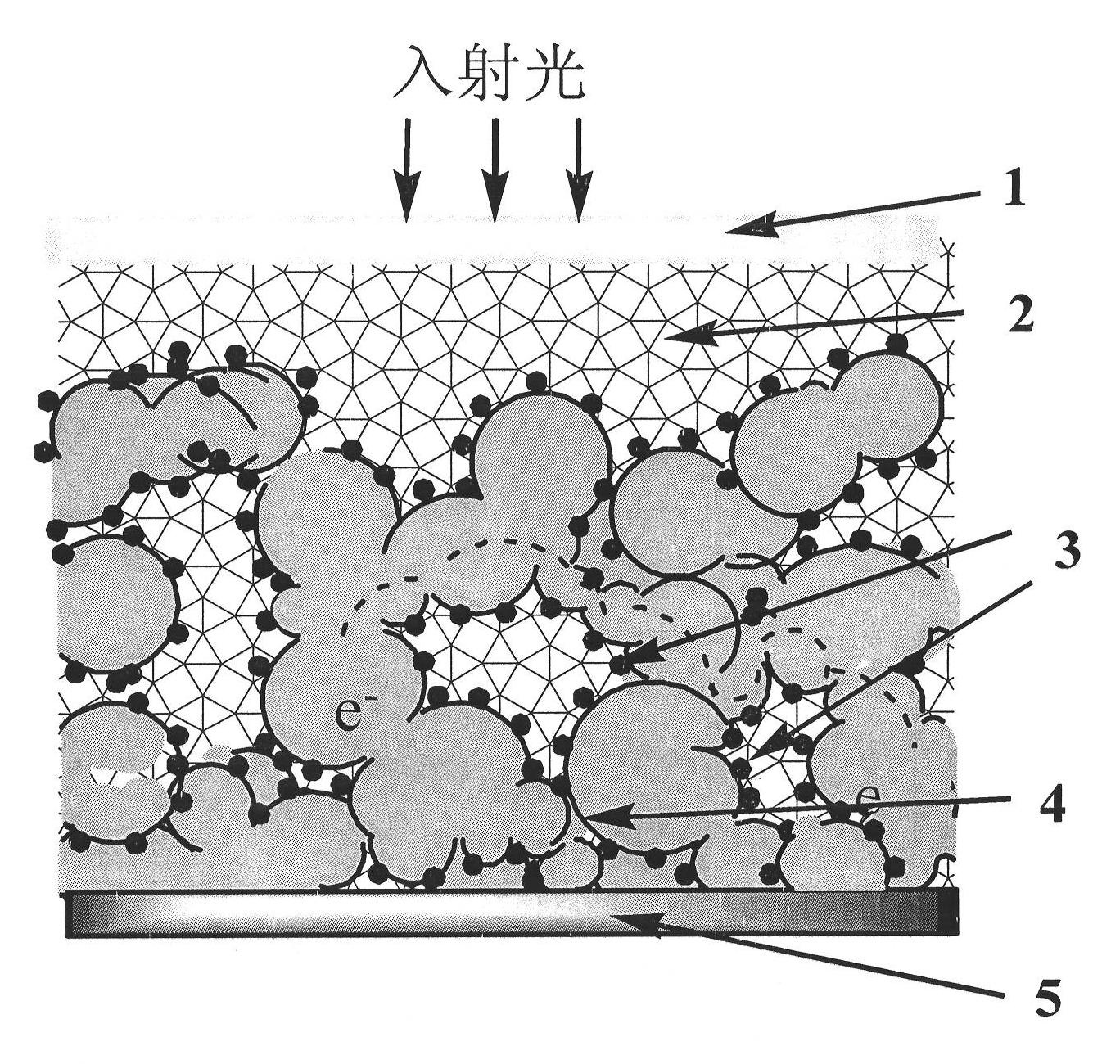

Composite thin film solar cell taking microcrystalline silicon layer as incident layer and preparation method thereof

A technology of composite thin film and microcrystalline silicon layer, applied in circuits, capacitors, photovoltaic power generation, etc., can solve the problems of poor liquid stability, high preparation cost, low preparation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Solid blackdye dye-sensitized TiO 2 Nanocrystalline composite thin-film solar cells with a microcrystalline silicon layer as the incident layer, and SnO doped with fluorine 2 Conductive layer, microcrystalline silicon hole transport layer, blackdye dye-sensitized TiO 2 nanocrystalline porous membrane and a steel sheet substrate coated with a titanium metal layer, the blackdye dye-sensitized TiO 2 The nanocrystalline porous membrane was coated on a steel sheet substrate coated with a titanium metal layer, and the microcrystalline silicon hole transport layer was deposited on blackdye dye-sensitized TiO 2 Formation of solid-state blackdye dye-sensitized TiO on nanocrystalline porous membranes 2 Composite thin films of nanocrystalline microcrystalline silicon made of SnO doped with fluorine 2 The conductive layer is plated on solid blackdye dye-sensitized TiO 2 Formation of Fluorine-doped SnO on Nanocrystalline Microcrystalline Silicon Composite Films 2 Conductive lay...

Embodiment 2

[0086] Solid blackdye dye-sensitized TiO 2 Nanocrystalline composite thin-film solar cells with a microcrystalline silicon layer as the incident layer, and SnO doped with fluorine 2 Conductive layer, microcrystalline silicon hole transport layer, blackdye dye-sensitized TiO 2 nanocrystalline porous membrane and a steel sheet substrate coated with an aluminum metal layer, the blackdye dye-sensitized TiO 2 The nanocrystalline porous membrane was coated on a steel sheet substrate coated with an aluminum metal layer, and the microcrystalline silicon hole transport layer was deposited on blackdye dye-sensitized TiO 2 Formation of solid-state blackdye dye-sensitized TiO on nanocrystalline porous membranes 2 Composite thin films of nanocrystalline microcrystalline silicon made of SnO doped with fluorine 2 The conductive layer is plated on solid blackdye dye-sensitized TiO 2 Formation of Fluorine-doped SnO on Nanocrystalline Microcrystalline Silicon Composite Films 2 Conductive l...

Embodiment 3

[0090] Solid blackdye dye-sensitized TiO 2 Nanocrystalline composite thin-film solar cells with a microcrystalline silicon layer as the incident layer, and SnO doped with fluorine 2 Conductive layer, microcrystalline silicon hole transport layer, blackdye dye-sensitized TiO 2 nanocrystalline porous membrane and a steel sheet substrate coated with a copper metal layer, the blackdye dye-sensitized TiO 2 The nanocrystalline porous membrane was coated on a steel sheet substrate coated with a copper metal layer, and the microcrystalline silicon hole transport layer was deposited on blackdye dye-sensitized TiO 2 Formation of solid-state blackdye dye-sensitized TiO on nanocrystalline porous membranes 2 Nanocrystalline microcrystalline silicon composite thin films, consisting of a fluorine-doped SnO2 conductive layer were plated on solid blackdye dye-sensitized TiO 2 A fluorine-doped SnO2 conductive layer surface electrode is formed on the nanocrystalline microcrystalline silicon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com