Catalyst for preparing low-carbon olefin through one-step conversion of synthesis gas and preparing method and application thereof

A technology of low-carbon olefins and catalysts, which is applied in the field of catalysts and preparations for one-step conversion of synthesis gas to low-carbon olefins, which can solve the problems of low olefin selectivity and poor product distribution, and achieve low selectivity, good dispersion, and improved selectivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

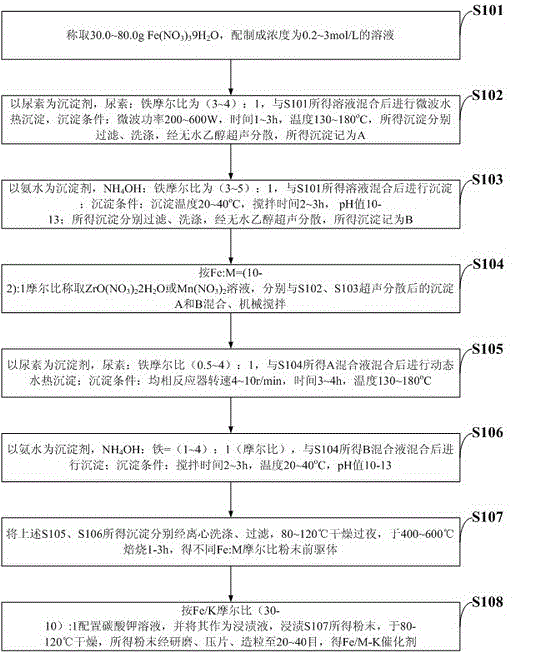

[0027] Such as figure 1 As shown, the preparation method of the catalyst for the one-step conversion of synthesis gas to low-carbon olefins in the embodiment of the present invention comprises the following steps:

[0028] S101: Weigh 30.0~80.0g Fe(NO 3 ) 3 •9H 2 O, prepared into a solution with a concentration of 0.2~3mol / L;

[0029] S102: Use urea as precipitant, urea:iron molar ratio is (3~4):1, mix with the solution obtained in S101 and carry out microwave hydrothermal precipitation, precipitation conditions: microwave power 200~600W, time 1~3h, temperature 130 ~180 o C, the obtained precipitate was filtered, washed, and ultrasonically dispersed in absolute ethanol, and the obtained precipitate was recorded as A;

[0030] S103: Use ammonia water as precipitant, NH 4 OH: iron molar ratio is (3~5): 1, mixed with the solution obtained from S101 to precipitate; precipitation conditions: precipitation temperature 20 ~ 40 o C, the stirring time is 2~3h, the pH value is 10...

Embodiment 1

[0039] Weigh Fe(NO 3 ) 3 •9H 2 O 75.90g and urea 33.85g were prepared into a 120 mL solution with deionized water. Transfer the above solution into the sample dissolving cup of TFM material, under microwave pressure 1.6MPa, power 500W, 170 o C was heated for 2h. Centrifuge and wash the above precipitated solution to neutrality, add 60 mL of absolute ethanol and centrifuge twice, pour off the supernatant and add 70 mL of absolute ethanol for ultrasonication for 0.5 h, and then separate the supernatant to obtain the iron precursor. Weigh ZrO 2 (NO 3 ) 2 • 2H 2 O 4.40g, urea 2.00g, add 80mL deionized water and stir to dissolve, mix the solution with the aforementioned iron precursor and put it into a high-pressure reactor, use a homogeneous reactor for dynamic precipitation, the speed is 5r / min, 160 o C kept for 3h. Centrifugal washing after reaction, 100 o C drying 10h, at 550 o After roasting C for 3 hours, grind it evenly to obtain a dry powder. Take 4.00g of the a...

Embodiment 2

[0041] Weigh Fe(NO 3 ) 3 •9H 2 O50.60g and urea 22.57g were prepared into 80 mL solution with deionized water. Transfer the above solution into the sample dissolving cup of TFM material, under microwave pressure 1.6MPa, power 400W, 160 o C heated for 3h. Centrifuge and wash the above precipitate until neutral, add 60 mL of absolute ethanol and centrifuge twice, pour off the supernatant and add 50 mL of absolute ethanol for ultrasonication for 0.5 h, then separate the supernatant to obtain the iron precursor. Weigh ZrO 2 (NO 3 ) 2 • 2H 2 O 5.58g, urea 2.50g, add 95mL deionized water and stir to dissolve, mix the solution with the aforementioned iron precursor and put it into a high-pressure reactor, use a homogeneous reactor to carry out dynamic precipitation, rotating speed 5r / min, 170 o C kept for 3h. Centrifugal wash after reaction, 120 o C drying 12h, at 500 o After roasting C for 3 hours, grind it evenly to obtain a dry powder. Take 4.00g of the above dry powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com