Sampling device of gaseous contaminant in material crushing process

A sampling device and pollutant technology, which is applied in the field of sampling devices for gaseous pollutants in the material crushing process, can solve the problems of lack of actual data, pollutant release and sample sampling technology and devices without research precedent, and pollution prevention and control work cannot be effectively obtained development and other issues to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1, this device is used to test the gaseous pollutants in the crushing process of FR-4 copper clad laminates. Targets to be measured: phenolic compounds, hydrogen bromide, benzene, toluene, xylene, ethylbenzene, styrene. The sampling rate of phenolic absorption solution, hydrogen bromide absorption solution and activated carbon adsorption tube is 0.5L / min, the sampling rate of Tenax-GC tube is 0.3L / min, and the sampling time is 40min. At this time, the mass of crushed material is 1.8kg. After the sampling is completed, further analysis and testing are carried out. The detection limit requirements: toluene, ethylbenzene, xylene, styrene 0.004mg / m 3 , phenols 0.03mg / m 3 , hydrogen bromide 0.10mg / m 3 . The analysis result is: Benzene 0.140mg / m 3 , toluene 0.014mg / m 3 , ethylbenzene 0.011mg / m 3 , Xylene 0.033mg / m 3 , Styrene was not detected (3 ), hydrogen bromide was not detected (3 ), phenols were not detected (3 )

Embodiment 2

[0018] Example 2, the device is used to test the gaseous pollutants in the crushing process of the FR-4 circuit board. Targets to be measured: phenolic compounds, hydrogen bromide, benzene, toluene, xylene, ethylbenzene, styrene. Adoption process and analysis test method are identical with embodiment 1. The analysis result is: Benzene 0.081mg / m 3 , toluene 0.008mg / m 3 , ethylbenzene was not detected (3 ), xylene was not detected (3 ), styrene was not detected (3 ), hydrogen bromide was not detected (3 ), phenols were not detected (3 )

Embodiment 3

[0019] Embodiment 3, using the device to test the gaseous pollutants in the crushing process of FR-4 circuit boards with components. Targets to be measured: phenolic compounds, hydrogen bromide, benzene, toluene, xylene, ethylbenzene, styrene. Adoption process and analysis test method are identical with embodiment 1. The analysis result is: Benzene 0.248mg / m 3 , toluene 0.007mg / m 3 , ethylbenzene 0.013mg / m 3 , Xylene 3.13mg / m 3 , Styrene 0.023mg / m 3 , hydrogen bromide was not detected (3 ), phenols were not detected (3 ).

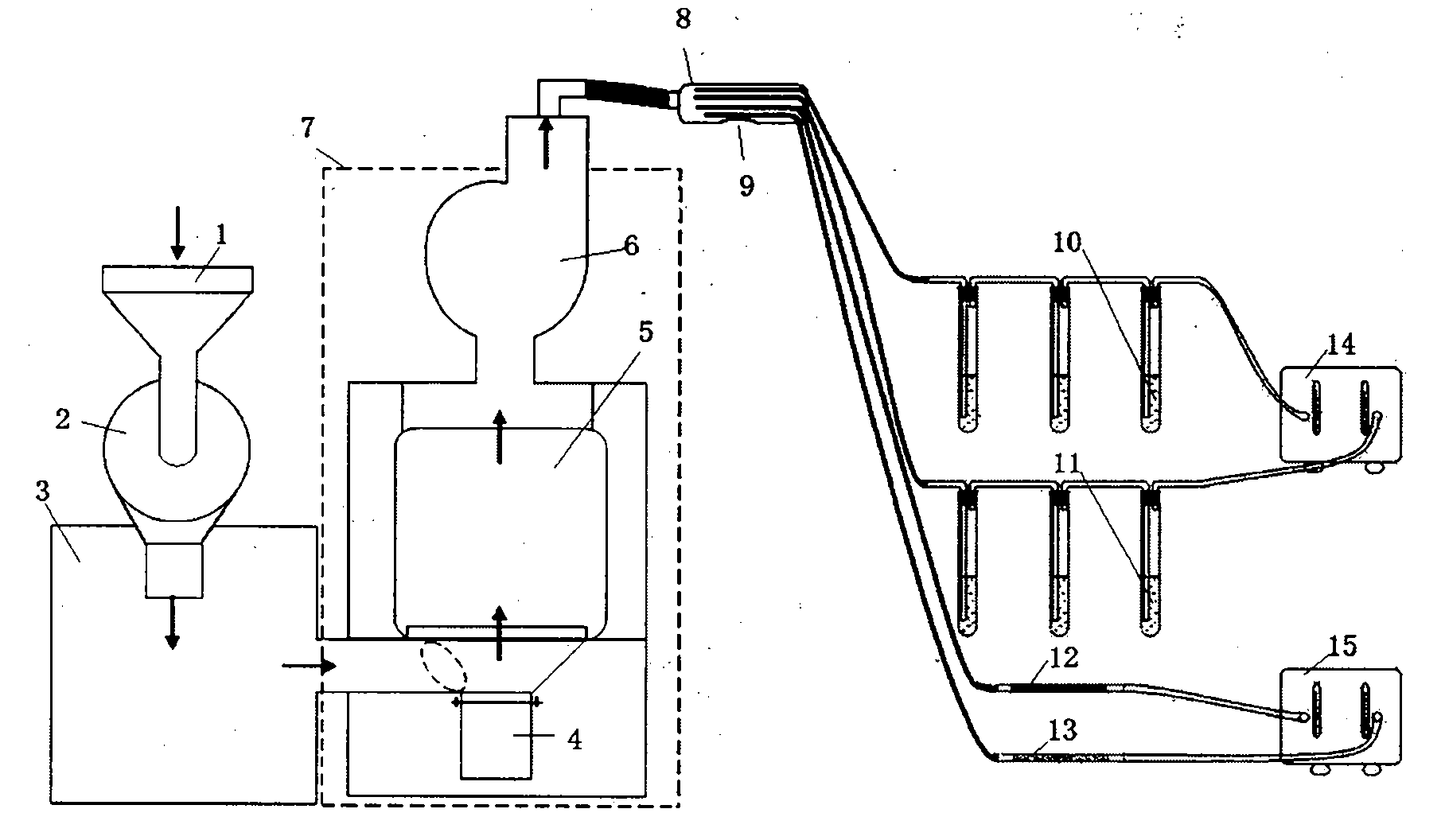

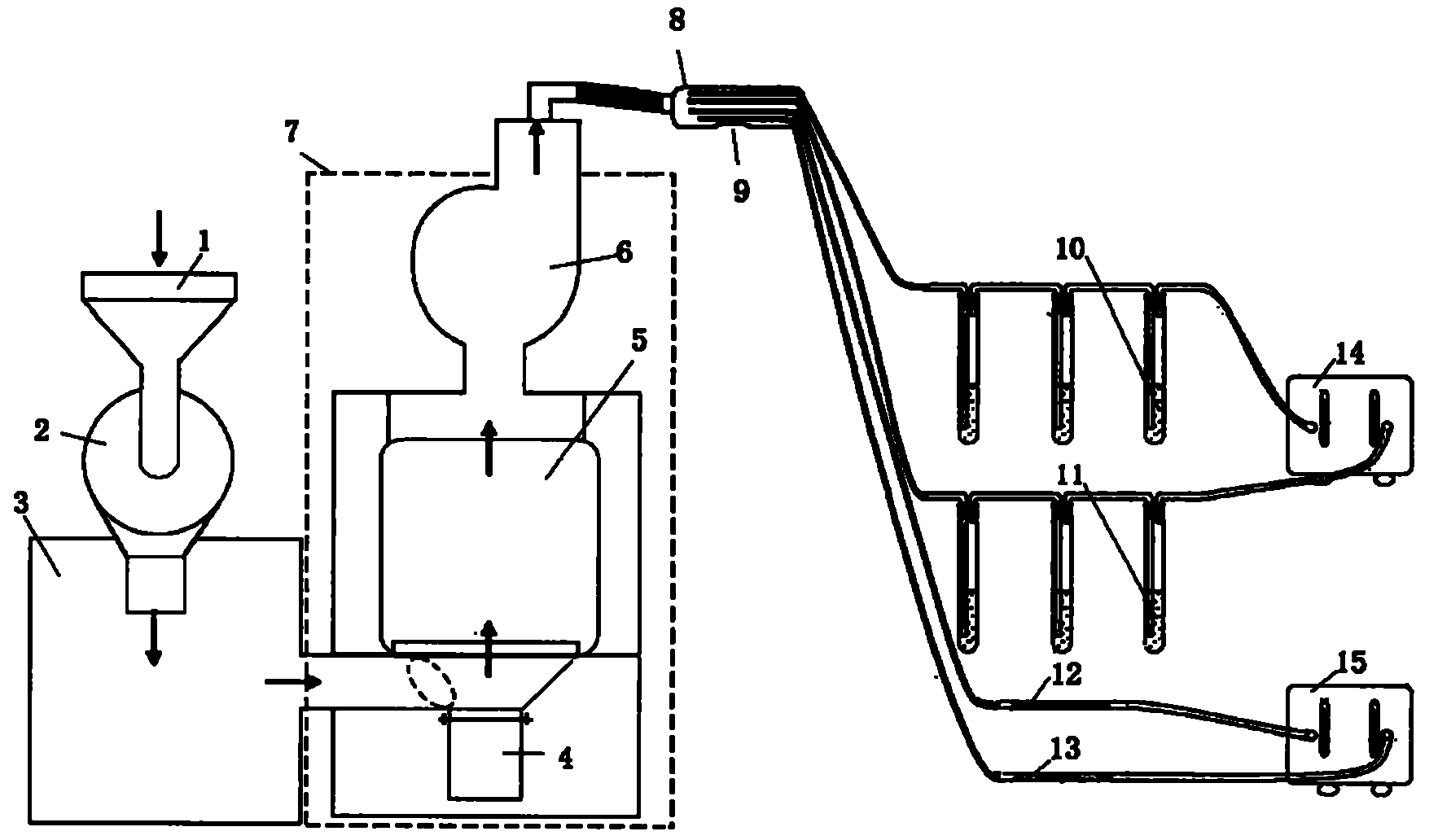

[0020] In the attached drawings: 1 is the feed port; 2 is the pulverizer drum; 3 is the undersize storage box; 4 is the dust collection cylinder; 5 is the dust bag; 6 is the induced draft fan; 7 is the pulverizer shell; Buffer tube; 9 is the gas splitter; 10 is the phenolic absorption liquid; 11 is the hydrogen bromide absorption liquid; 12 is the activated carbon adsorption tube; 13 is the Tenax-GC tube; 14 is the first sampler; 15 is the second samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com