Pure-culture solid-state fermentation apparatus capable of gas-phase inoculation and feeding, and method thereof

A solid fermentation device and solid fermentation technology, which are applied in sterilization methods, solid-phase fermentation bioreactors, and methods of supporting/fixing microorganisms, etc. and other problems, to achieve the effect of shortening fermentation time, small investment and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

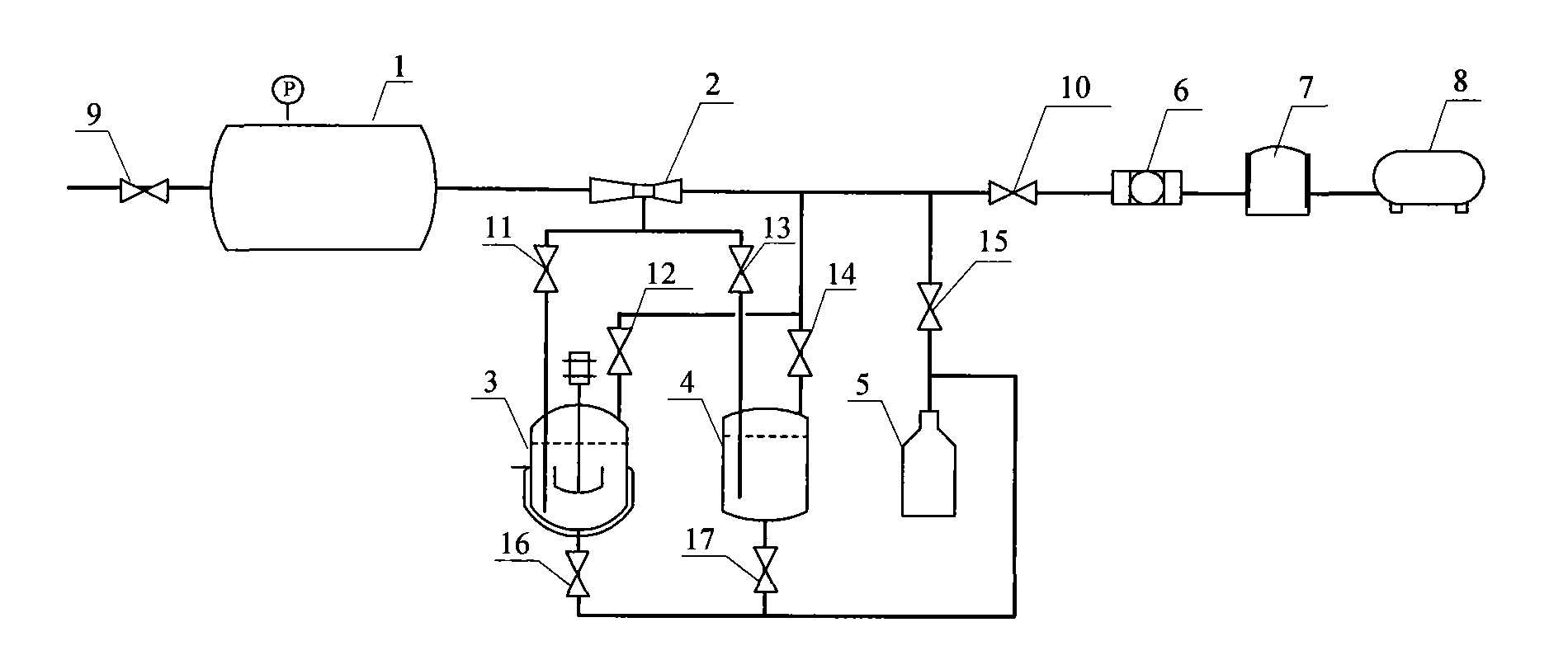

[0045] The strain of solid fermentation is A. vinelandii. First configure the liquid culture medium of nitrogen-fixing bacteria, add it into the seed tank 3, open the disinfection valve 16 and feed steam to eliminate the culture medium. After cooling, insert the bacterial suspension obtained from the inclined plane and cultivate at 30°C with a stirring speed of 130rpm. After culturing for 10 hours, a liquid strain with good fluidity was obtained. Prepare solid culture medium during this period (preparate liquid culture medium first, then add peat moss according to solid-liquid ratio 1: 3), be placed on the shallow plate of solid fermenter 1, material layer height is 2cm. Open the gas path end valve 15 and use steam to sterilize the solid medium at 120°C for 30min, and then cool it down to 30°C.

[0046] After the cultivation of the liquid bacteria is completed, turn on the air compressor, valves 15, 12 at the gas path and valve 11 at the discharge end, and adjust the air spe...

Embodiment 2

[0048] The strain of solid fermentation is A. vinelandii. First configure the liquid culture medium of nitrogen-fixing bacteria, add it into the seed tank 3, open the disinfection valve 16 and feed steam to eliminate the culture medium. After cooling, insert the bacterial suspension obtained from the inclined plane and cultivate at 30°C with a stirring speed of 130rpm. After culturing for 10 hours, a liquid strain with good fluidity was obtained. Prepare solid culture medium during this period (preparate liquid culture medium first, then add peat moss according to solid-liquid ratio 1: 3), be placed on the shallow plate of solid fermenter 1, material layer height is 2cm. Open the gas path end valve 15 and use steam to sterilize the solid medium at 120°C for 30min, and then cool it down to 30°C.

[0049] After the cultivation of the liquid bacteria is completed, turn on the air compressor, and the valve 15 at the gas path end, the valve 12 at the gas path end, and the valve 1...

Embodiment 3

[0053] The fermentation strain is Penicillium decumbens.

[0054] Cultivate the seed solution first, and after cultivating at 30°C for 20 hours, adjust the air flow rate to 2.0m 3 / hr, inoculated onto the solid medium (with the wheat straw with a particle diameter of about 2mm as the solid matrix), the material layer thickness of the solid medium is 3cm, and the inoculum size is 10%. The culture is carried out by the method of periodic variable pressure, the pressure is periodically varied between 0.5MPa and 1.8MPa, and the high and low pressure are maintained for 3 minutes and 3 minutes respectively. Keep the humidity of the reactor at 50-80% during the continuous fermentation. If the humidity is lower than the set value, the sterilized sterile water will be sent into the reactor in the form of mist through the airflow. The whole fermentation cycle is 114hr, β-Gase reaches 38.85IU g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com