Water atomization diffusion alloy powder and preparation method thereof

A technology of diffusion alloying and manufacturing method, applied in the field of powder metallurgy, can solve the problems of reducing the yield of sintered products, segregation of alloy elements, low strength and hardness parameters, etc., to improve mechanical properties, reduce bulge or agglomeration, high compression sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

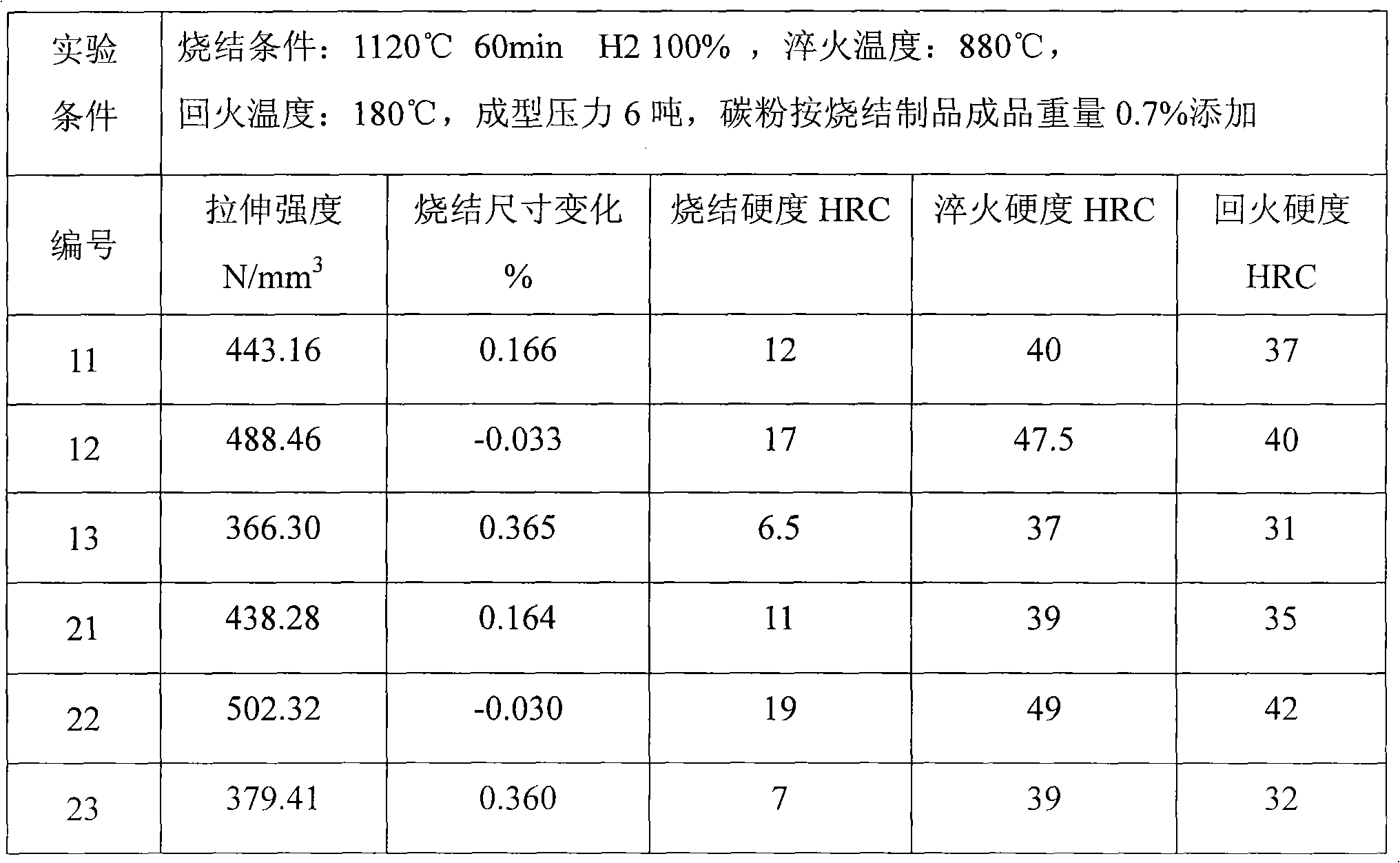

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be further described below in conjunction with examples:

[0014] The manufacturing method of water atomized diffusion alloy powder is to add ferromolybdenum in the smelting process to make water atomized pre-alloyed powder, then add nickel powder and copper powder to the product through diffusion treatment. The operation steps are as follows:

[0015] 1) Smelting, smelting scrap steel with an electric furnace to obtain molten steel with uniform and stable composition and few impurities. Add a molybdenum-iron alloy with a Mo content of 50-60% to the molten steel and stir until it is uniform;

[0016] 2) Water atomization process parameters, tapping temperature 1600~1800℃, atomization start temperature 1580-1700℃, atomization termination temperature 1550-1650℃, molten steel flow diameter 30~35mm, molten steel atomization speed 2.8- 4.5kg / s, atomization pressure 60~160Mpa, high pressure water pressure 70-125MPa, flow 140-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com