O-Sialon porous material prepared by gel-casting and preparation method thereof

A porous material, gel injection molding technology, applied in the field of porous ceramic materials, can solve the problems of uneven distribution of pore structure and difficult control of porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

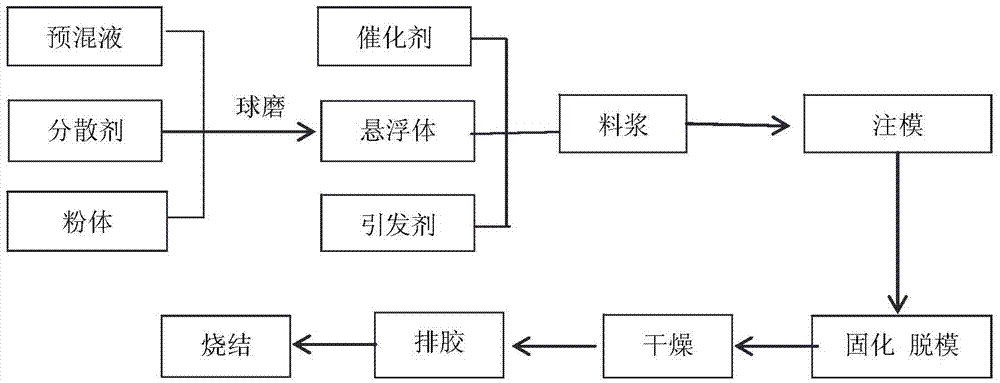

Method used

Image

Examples

Embodiment 1

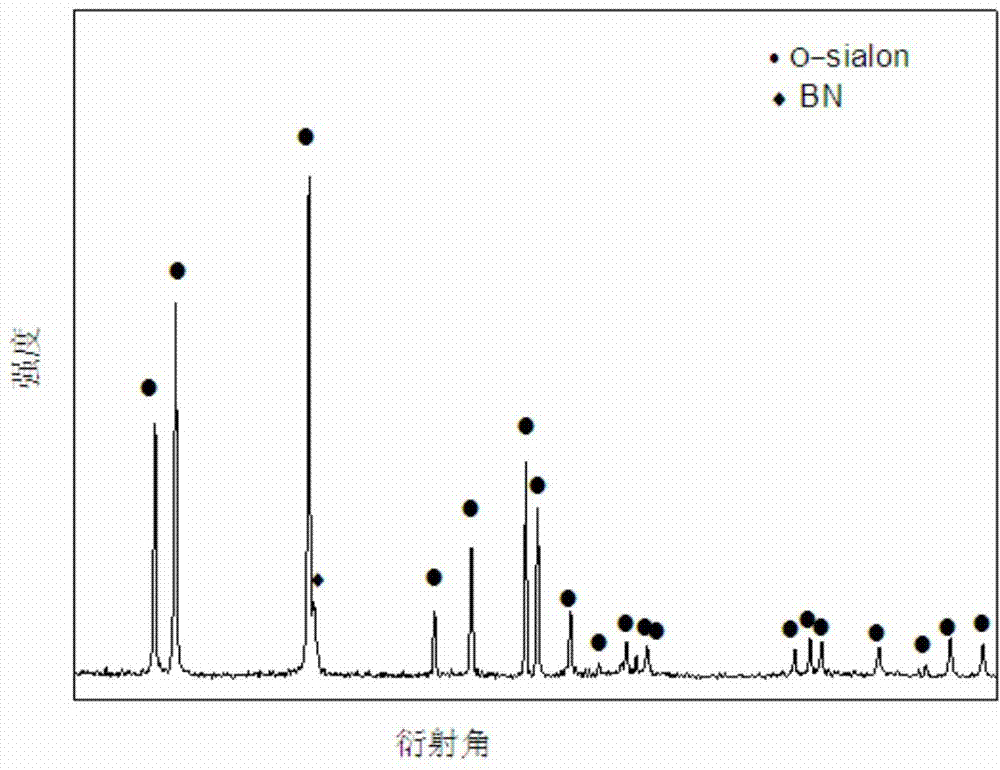

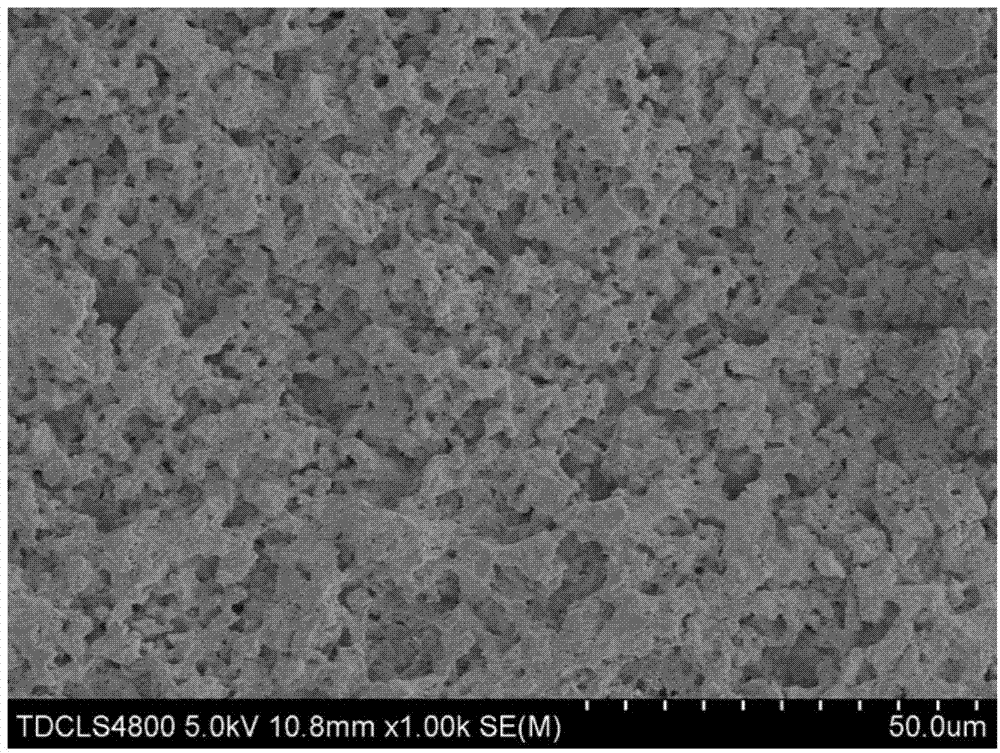

[0027] Embodiment 1: with α-Si 3 N 4 , SiO 2 , Al 2 o 3 , h‐BN as raw material, with Y 2 o 3 and MgO as a sintering aid, where D of h‐BN 50 0.1 μm.

[0028] (1) Ingredients: According to the powder mass ratio Si 3 N 4 : SiO 2 :Al 2 o 3 : BN=58 parts: 26 parts: 4 parts: 5 parts of ingredients, then add 4 parts of Y 2 o 3 and 3 parts of MgO, mixed evenly to obtain a composite powder.

[0029] (2) Preparation of slurry: according to the mass ratio AM: MBAM: H 2 O=10 parts: 2 parts: 88 parts Prepare the premix, add 90 parts of the composite powder prepared in step (1) to 100 parts of the premix, add 3 parts of dispersant, and mix in the stirring mill for 3 hours.

[0030] (3) Preparation of green body: After vacuum defoaming the suspension, add 2 parts of 0.02g / ml catalyst and 6 parts of 0.01g / ml initiator into the slurry, mix well, and then inject the slurry into the mold , room temperature curing molding, demoulding. Put the demoulded body into a closed space, a...

Embodiment 2

[0034] Embodiment 2: with α-Si 3 N 4 , SiO 2 , Al 2 o 3 , h‐BN as raw material, with Y 2 o 3 and MgO as a sintering aid, where D of h‐BN 50 is 1 μm.

[0035] (1) Ingredients: According to the powder mass ratio Si 3 N 4 : SiO 2 :Al 2 o 3 :BN=48:20:11:15 Ingredients, add 3 parts of Y 2 o 3 and 3 parts of MgO, mixed evenly to obtain a composite powder.

[0036] (2) Preparation of slurry: according to the mass ratio AM: MBAM: H 2 O=7 parts: 1 part: 92 parts Prepare the premix, add 100 parts of the composite powder prepared in step (1) to 100 parts of the premix, add 5 parts of dispersant, and ball mill for 2 hours.

[0037] (3) Preparation of green body: After vacuum defoaming the suspension, add 4 parts of 0.02g / ml catalyst and 8 parts of 0.03g / ml initiator into the slurry, mix well, and then inject the slurry into the mold , room temperature curing molding, demoulding. Put the demoulded body into a closed space, avoid air flow, place it for more than 24 hours, a...

Embodiment 3

[0041] Embodiment 3: with α-Si 3 N 4 , SiO 2 , Al 2 o 3 , h‐BN as raw material, with Y 2 o 3 and MgO as a sintering aid, where D of h‐BN 50 is 6 μm.

[0042] (1) Ingredients: According to the powder mass ratio Si 3 N 4 : SiO 2 :Al 2 o 3 :BN=52:22:12:10 ingredients, add 3 parts of Y 2 o 3 and 1 part of MgO, mixed evenly to obtain a composite powder.

[0043] (2) Preparation of slurry: according to the mass ratio AM: MBAM: H 2 O=12 parts: 3 parts: 85 parts Prepare the premix, add 80 parts of the powder prepared in step (1) to 100 parts of the premix, then add 2 parts of dispersant, and mix in the stirring mill for 4 hours.

[0044] (3) Preparation of green body: After vacuum defoaming the suspension, add 1 part of 0.03g / ml catalyst and 5 parts of 0.02g / ml initiator into the slurry, mix well, and then inject the slurry into the mold , room temperature curing molding, demoulding. Put the demoulded body into a closed space, avoid air flow, place it for more than 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com