High-frequency high-voltage high-power power supply for electrostatic dust removal

A high-power power supply, high-frequency and high-voltage technology, used in electrostatic separation, output power conversion devices, DC power input conversion to DC power output, etc., can solve the problem of slow dynamic response speed, large output ripple, low conversion efficiency, etc. problem, to achieve the effect of fast shutdown and start-up, fast adjustment and cost saving

Inactive Publication Date: 2011-06-15

ZHEJIANG ELECTRIC POWER DESIGN INST +1

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditional high-voltage DC power supplies mostly use thyristor phase-controlled rectification for power supply. This method first makes the three-phase power frequency through the thyristor voltage regulation, and then three-phase rectification after the transformer boosts the voltage. This method has the advantages of simple structure, large capacity, The control technology is mature, but the disadvantages are low conversion efficiency, large volume, heavy weight, high cost, slow dynamic response speed, and large output ripple

The dust removal effect alone is difficult to fully meet the emission limit of the new standard. In order to adapt to the new emission standard, the electrostatic dust removal equipment must be updated. Many factories combine bag dust removal to improve it. This method is costly and will cause secondary pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

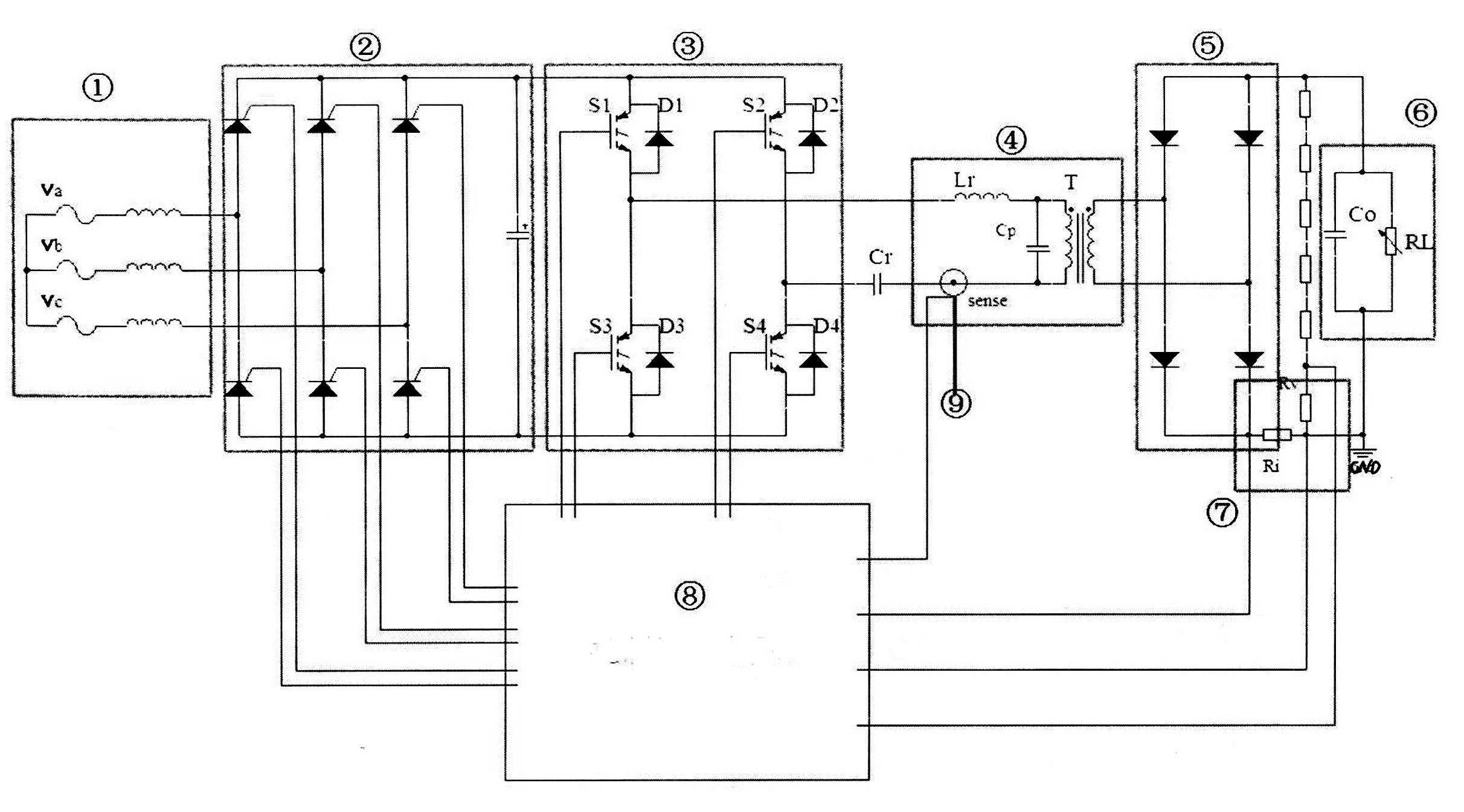

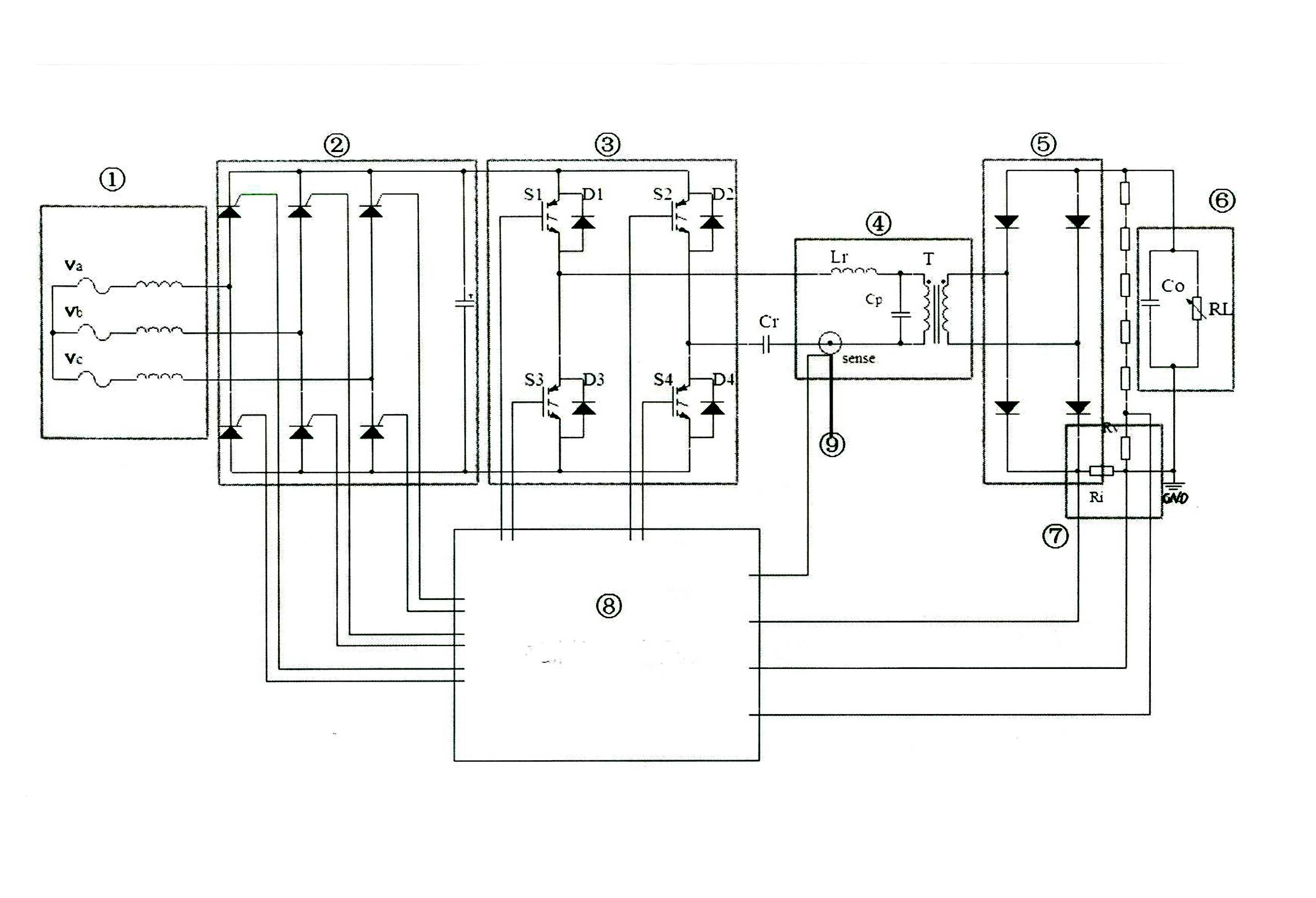

The invention discloses a high-frequency high-voltage high-power power supply for electrostatic dust removal, which mainly comprises a three-phase power-frequency power supply, a rectification part, an inverter part, a resonant circuit, a high-frequency transformer, a high-voltage rectifier bridge, a load and a control module. The rectification part consists of a thyristor rectification module capable of rectifying the power-frequency electric energy output by the three-phase power supply into direct current, and a filter capacitor; the back of the rectification part is connected with the inverter part consisting of a high-frequency full-bridge Insulated Gate Bipolar Transistor (IGBT) inverter capable of inverting the direct current into high-frequency square wave; the resonant circuit consisting of a series inductor Lr, a series capacitor Cr and a parallel capacitor Cp and supplying power to the post-stage circuit in a resonant manner is connected behind the inverter part. By the invention, the deficiency of the conventional electrostatic dust removing power supply can be compensated, the dust removing effect is improved, and the utilization ratio of electric energy can be increased.

Description

A high-frequency high-voltage high-power power supply for electrostatic dust removal technical field The invention relates to a high-frequency, high-voltage, and high-power power supply for electrostatic dust removal equipment in various factories. Background technique The rapid development of modern industry has brought enormous pressure to the environment, and the problem of environmental protection has become increasingly prominent and has become the focus of people's attention. Exhaust gas discharged during industrial production contains a large amount of dust, which seriously affects air quality and is an important cause of air pollution. Therefore, the law stipulates that the exhaust gas of modern industrial enterprises must go through the dust removal step and can only be discharged after reaching the national standard. At present, dust removal generally adopts electrostatic dust removal method, and electrostatic precipitator has become an indispensable means of du...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02M7/12H02M3/335B03C3/66

Inventor 郭亮吴为麟丘文千张农徐为民沈洪流

Owner ZHEJIANG ELECTRIC POWER DESIGN INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com