PET flat filament drawing machine set

A wire-drawing and unit technology, applied in the direction of filament/thread forming, fabric, textile, etc., can solve the problem that PET cannot be flattened

Inactive Publication Date: 2011-06-15

黄美昌 +2

View PDF0 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the defect that PET cannot draw flat wire at present, and provide a kind of equipment that can use genuine PET material and PET mineral water bottle waste material as raw materials to manufacture plastic woven bags, especially a PET flat wire drawing unit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

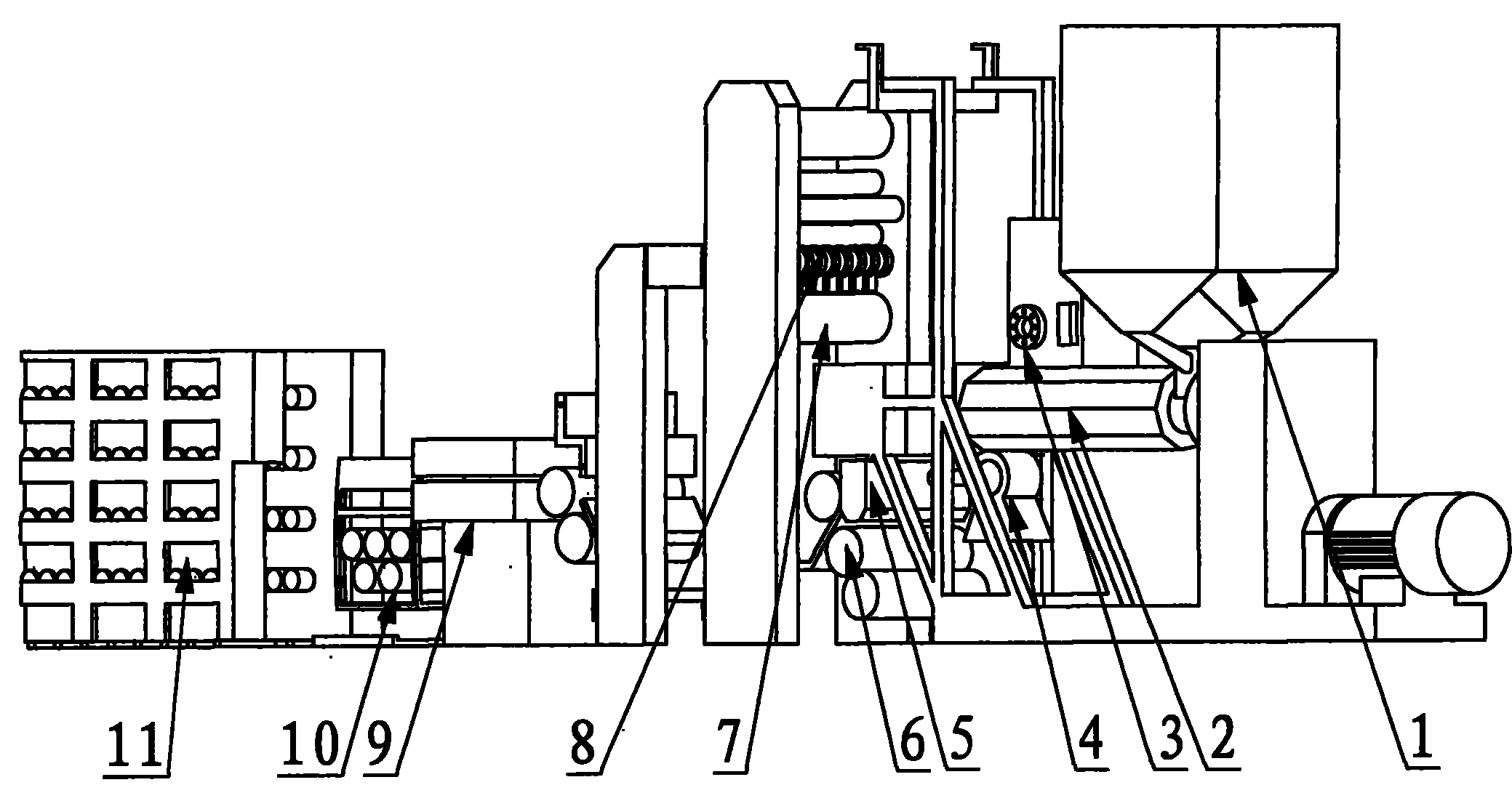

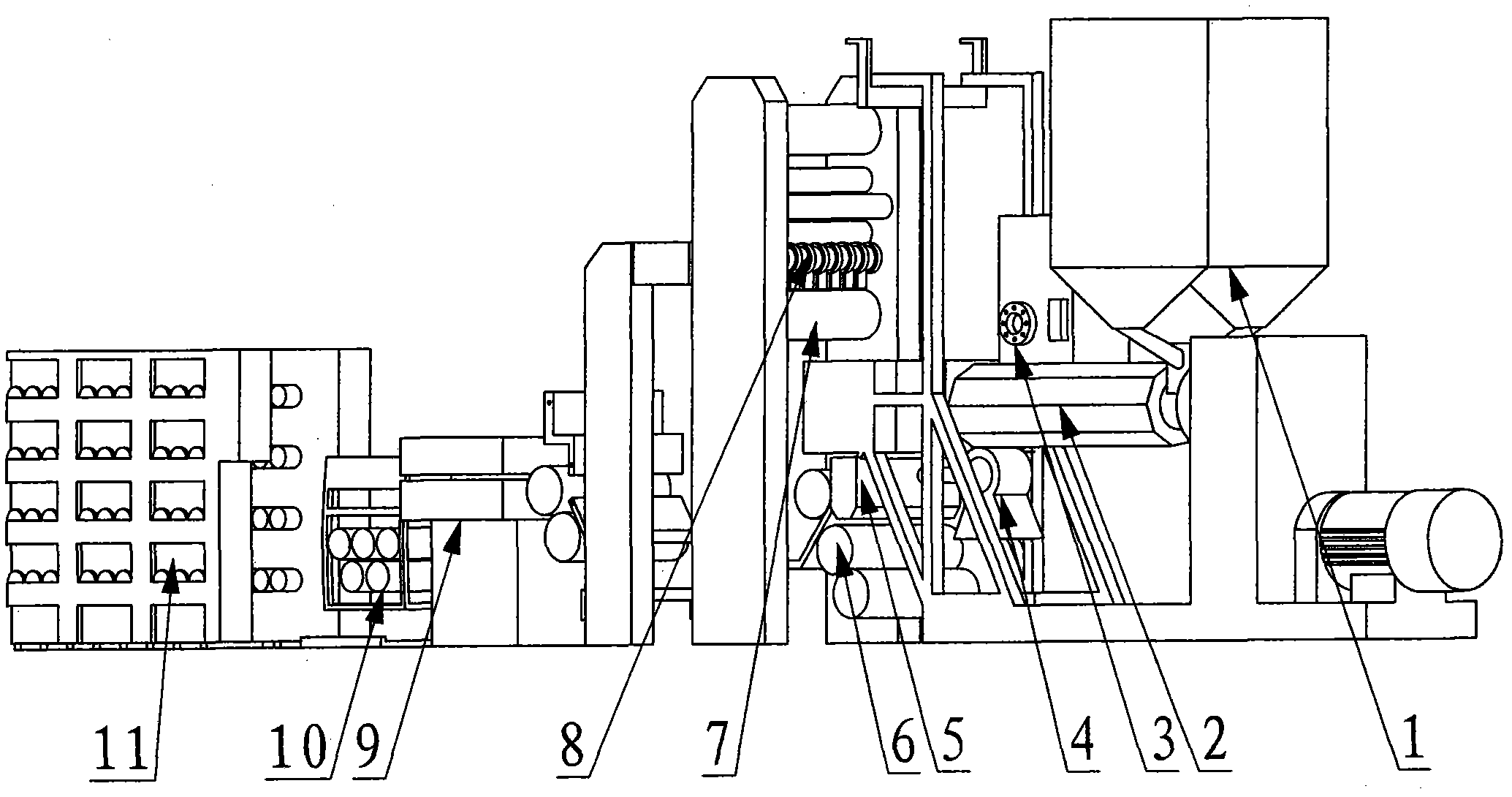

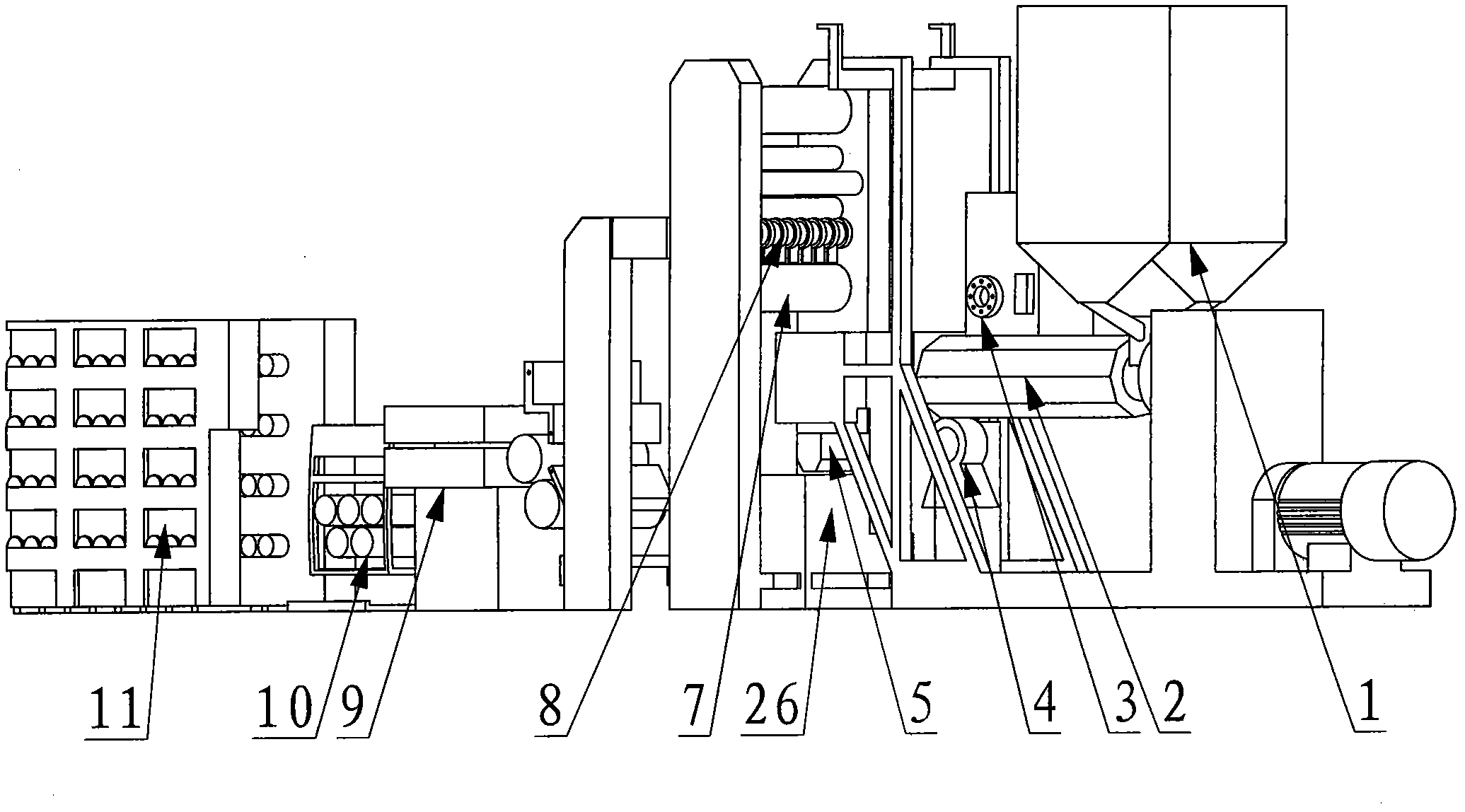

The invention discloses a polyethylene terephthalate (PET) flat filament drawing machine set, which is characterized by comprising dryers, an extruder, a filter, a metering pump, a die head, a cooling device, a traction device, a longitudinal cutting device, a heating device, a drawing device, and a rolling device; more importantly, the dryers are two or more than two vacuum drying tanks with heaters and stirrers, and the filter is a double-cylinder switch melt filter; and the dryers can ensure thorough drying of a PET raw material or mineral water bottle crushing material, and the filter can ensure that the mineral water bottle crushing material is subjected to flat filament drawing normally, so that the PET raw material or mineral water bottle crushing material is subjected to flat filament drawing for producing plastic woven bags. The PET flat filament drawing machine set has the advantages that: the strength of the woven bags is improved, raw materials are saved, and waste PET plastics are easy to recycle.

Description

A PET flat wire drawing unit Technical field The invention relates to the field of plastic textile machinery, in particular to a PET flat wire drawing unit technical background At present, the plastic flat wire drawing unit manufactured, sold and used at home and abroad uses polypropylene resin (PP) or polyethylene (PE) as raw materials to make flat yarns and then weave them into plastic woven bags. This kind of plastic flat wire drawing The unit cannot use polyester (PET) as a raw material, and PET has better mechanical properties than PP or PE. If PET is used as a raw material to make flat yarn into a woven bag, it can not only double the strength of the woven bag, but also save the amount of raw material. Recycling a large amount of PET mineral water bottle waste as raw materials to make flat yarn woven into woven bags for packaging items to achieve waste recycling and reuse. Therefore, many domestic experts and people with lofty ideals have studied and explored PET flat ya...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01D13/00D01D5/42D01D5/00D03D1/04

Inventor 黄美昌周传对陈崇锡

Owner 黄美昌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com