Polyphenylene sulfide/polyether sulfone-based compound material and preparation method thereof as well as wear-resistant part prepared from polyphenylene sulfide/polyether sulfone-based compound material

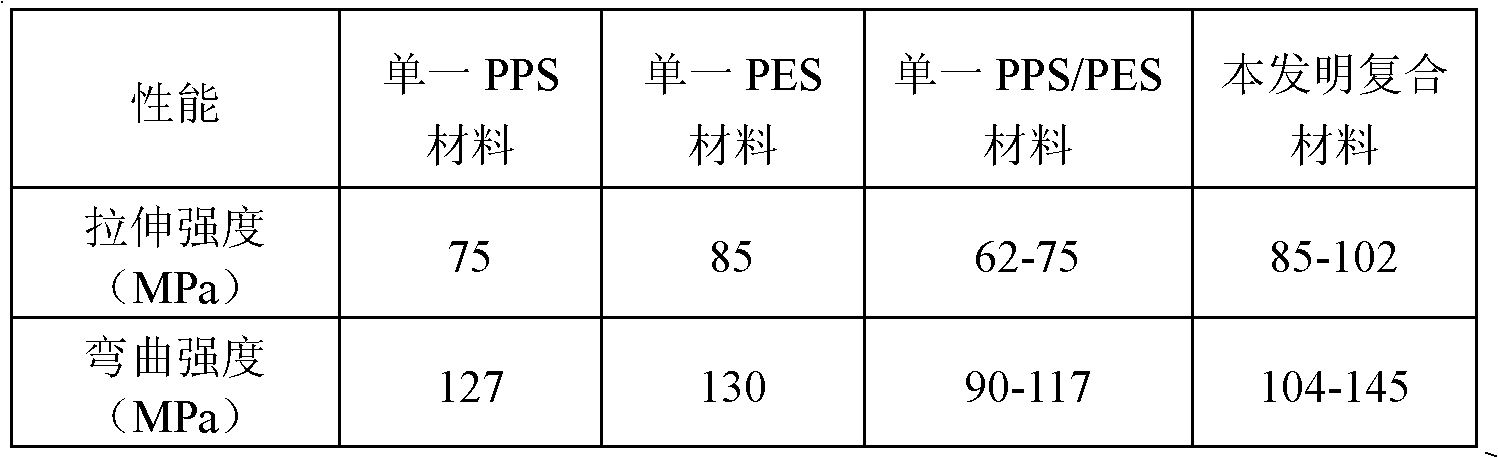

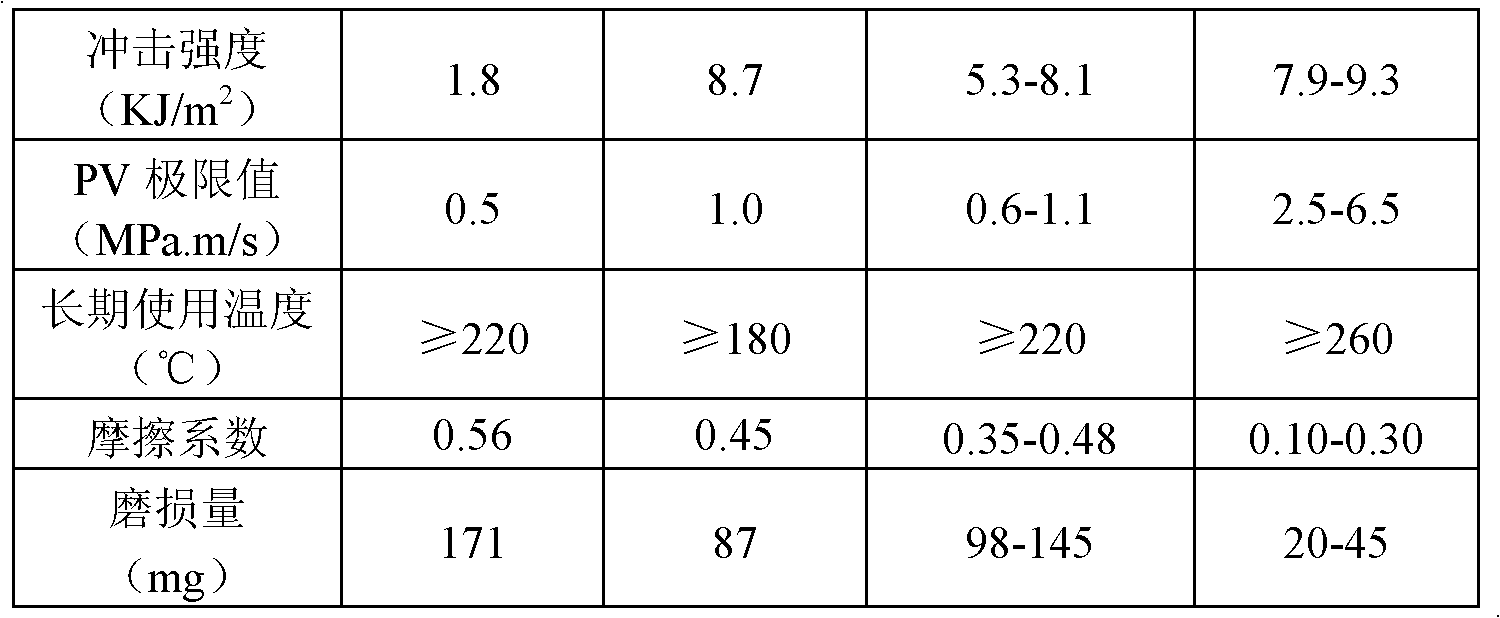

A technology of composite materials and polyphenylene sulfide, which is applied in the direction of mechanical equipment, bearing components, engine components, etc., can solve the problems of insufficient research on material properties and lack of guiding significance in production, and achieve low preparation costs, wide application range, The effect of improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides an embodiment of the preparation method of the above-mentioned PPS / PES-based composite material, comprising the following steps:

[0046] (a) First treat potassium titanate with coupling agent and dry it. For this purpose, you can use 1-3% of the weight of potassium titanate whiskers to mix evenly with potassium titanate after hydrolysis, and then dry it. , the preferred drying temperature is 90-110°C, the coupling agent is selected from, but not limited to KH550, KH570, and the use of other commonly used coupling agents in the industry does not affect the realization of the present invention;

[0047] (b) 30-50% PPS, 20-50% PES, 10-30% treated PTW, 8-12% PTFE and appropriate amount of processing aids are mixed and dried;

[0048] (c) using a mixer for mixing for 2-3 hours;

[0049] (d) After extrusion, pelletizing and drying, the product is formed. The extrusion step can be realized by any high-temperature twin-screw extruder; the ...

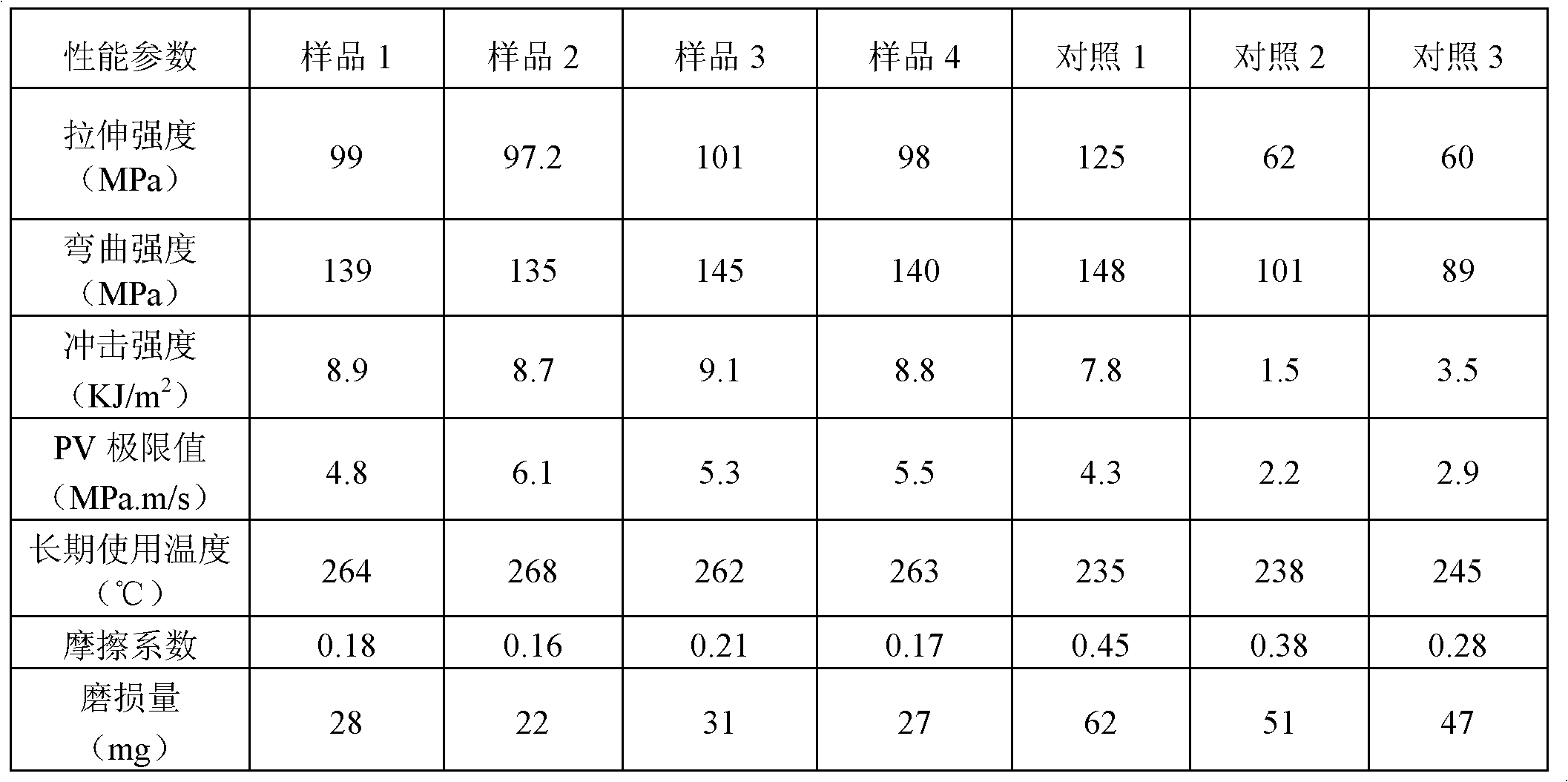

Embodiment 1

[0052] (a) Treat potassium titanate whiskers with the hydrolyzed coupling agent KH550 and bake at 100°C for 2 hours;

[0053] (b) The PPS of 37.5% by weight, the PES of 37.5%, the PTW of 15% processing and the PTFE of 10%, the antioxidant 1010 of 0.3%, the mineral oil of antioxidant 168 of 0.3% and 1% After mixing, dry in a drying oven at a temperature of 110°C for 2 hours;

[0054] (c) Adopt TM2 type vortex type high-efficiency mixer to mix materials for 3 hours;

[0055] (d) Twin-screw extrusion, blending, granulation and drying at 120° C. for 3 hours, followed by product molding with a high-temperature injection molding machine.

[0056] Taking the preparation of 1000g PPS / PES-based composite material as an example, first treat 150g potassium titanate with 4.5g coupling agent KH550 and dry it, then 375gPPS, 375gPES, 100g PTFE, treated potassium titanate whiskers, 3g The antioxidant 1010, 3g of antioxidant 168 and 10g of mineral oil were weighed according to the formula an...

Embodiment 2

[0058] (a) Treat potassium titanate whiskers with the hydrolyzed coupling agent KH550 and bake at 100°C for 2 hours;

[0059] (b) the weight percentage is 42% PPS, 28% PES, 20% processed PTW and 10% PTFE, 0.3% antioxidant 1010, 0.3% antioxidant 168 and 1% mineral oil After mixing, dry in a drying oven at a temperature of 110° C. for 2 hours;

[0060] (c) Adopt TM2 type vortex type high-efficiency mixer to mix materials for 3 hours;

[0061] (d) Twin-screw extrusion, blending, granulation and drying at 120° C. for 3 hours, followed by product molding with a high-temperature injection molding machine.

[0062] Taking the preparation of 1000g PPS / PES-based composite material as an example, first treat 200g potassium titanate with 6.0g coupling agent KH550 and dry it, then 420gPPS, 260gPES, 100g PTFE, treated potassium titanate whiskers, 3g The antioxidant 1010, 3g of antioxidant 168 and 10g of mineral oil were weighed according to the formula and mixed, dried in a drying oven a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com