Super capacitor of flexible package water system

A supercapacitor and flexible packaging technology, applied in capacitor parts, liquid electrolytic capacitors, capacitor casings/packages, etc., can solve the problems of large product weight and volume, complex production process, hard casing, etc., to achieve low cost and freedom of flexible packaging. The effect of easy combination and small product volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

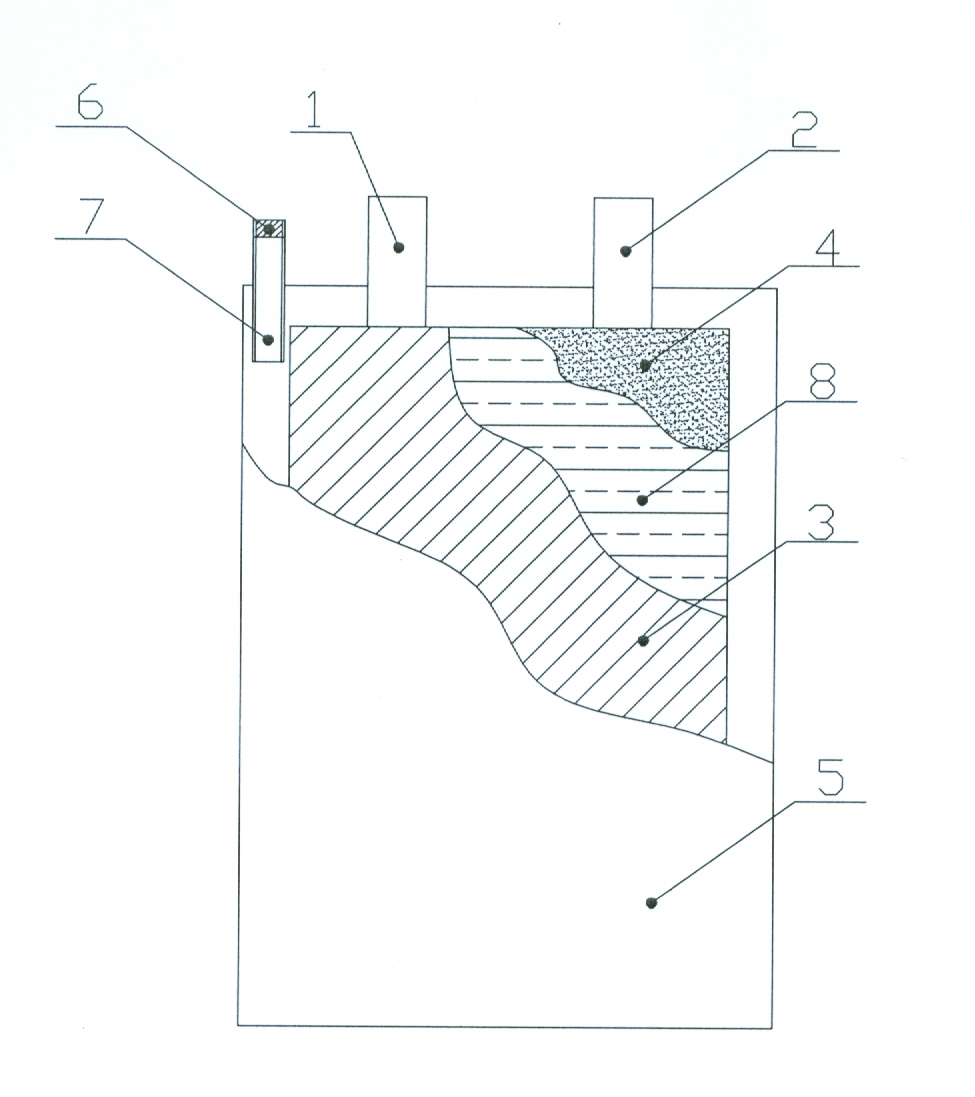

[0014] First, the supercapacitor positive pole piece 3 and the negative pole piece 4 are produced in a conventional manner, and the positive pole tab 1 and the negative pole tab 2 of the nickel-plated steel strip material are respectively welded on the pole pieces, and the positive pole piece 3 and the negative pole tab 2 of the welding tab are welded respectively. The negative pole pieces 4 are stacked sequentially, and are separated by a diaphragm 8 between the positive and negative poles. Then wrap the electrode with a flexible packaging film 5 made of polyethylene film, polypropylene film or aluminum-plastic film, put the exhaust pipe 7 made of polyethylene or polypropylene, and seal the surroundings of the flexible packaging film 5 with a heat sealer.

[0015] Inject 6mol / L potassium hydroxide electrolyte into the supercapacitor through the exhaust pipe 7, then put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com