Catalytic conversion method for producing high-cetane number light diesel oil and low-olefin gasoline

A technology for producing high cetane and light diesel oil, which is applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problem of high cost, and achieve the effects of reduced tendency to breakage, uniform temperature distribution, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of catalyst A is briefly described as follows:

[0039] Configuration 2 liters of silica concentration is 155g / L water glass solution and 1 liter of free acid is 148g / L, Al 2 o 3 Acidified aluminum sulfate solution with a content of 20g / L, the above two solutions enter the rapid mixer for reaction at the same time to obtain silica sol.

[0040] Add 465g of kaolin (Suzhou Kaolin Company, solid content 80% by weight) to the silica sol prepared above, and beat for 1 hour to obtain kaolin-silica sol.

[0041] Contains Al 2 o 3 124g of pseudo-boehmite (Shandong Aluminum Plant, Al 2 o 3 content is 33% by weight) and 450g deionized water mixed beating for 30 minutes, then adding 25 milliliters of concentration is 31% by weight of hydrochloric acid (acid / Al 2 o 3 Molar ratio is 0.2) peptization, continues beating for 2 hours, then adding 656g molecular sieve content is 32% by weight of ground DASY0.0 molecular sieve (being a kind of super stable Y ...

Embodiment

[0045] This example illustrates the production of high cetane number light diesel oil and low olefin catalytic gasoline by selective cracking reaction using the method provided by the present invention.

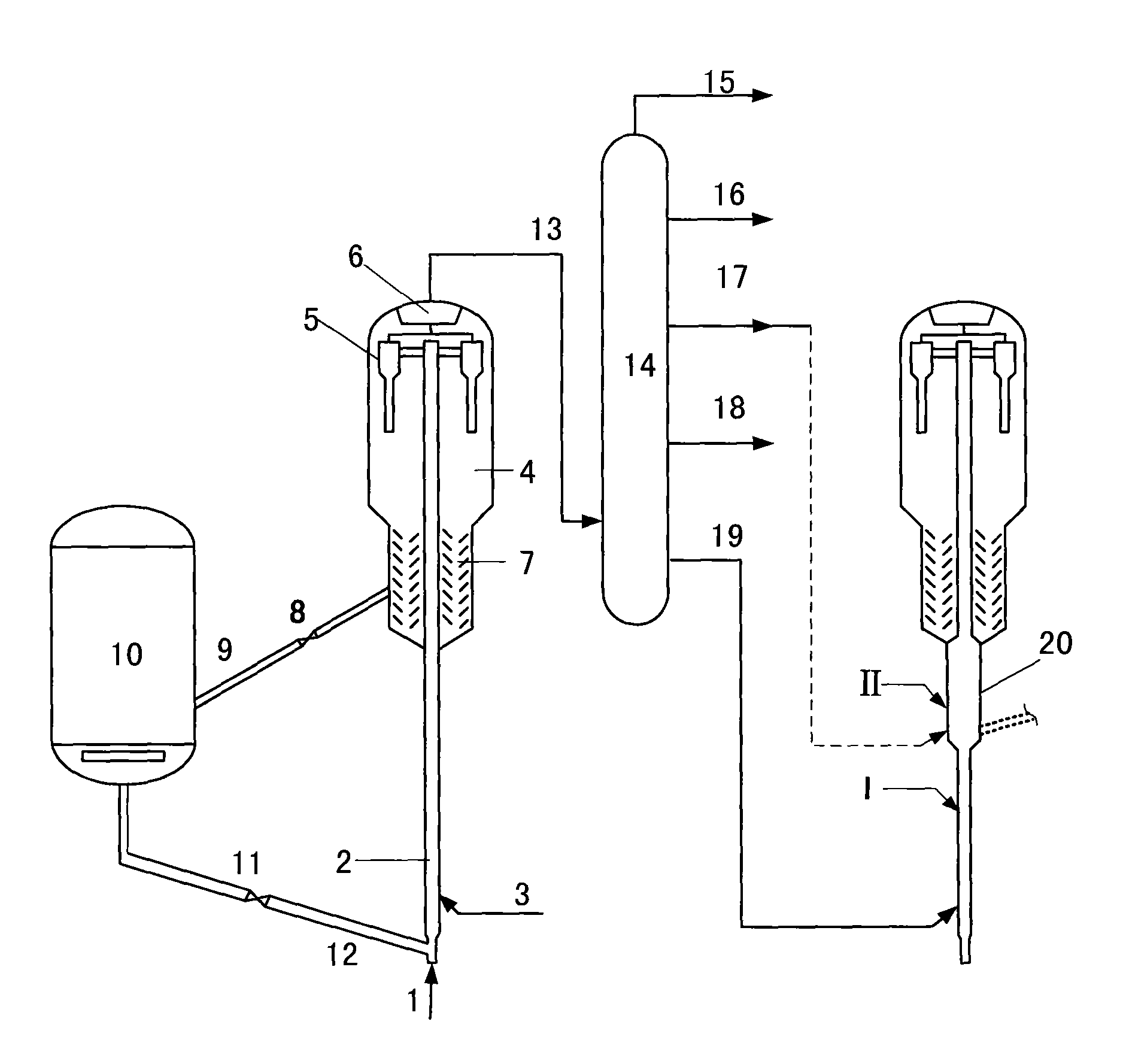

[0046] The flow chart of the medium-sized catalytic cracking unit is shown in Figure 1. The raw oil is injected into the riser reactor 2 through the pipeline 3, and it contacts and reacts with the catalyst A-1 lifted by water vapor at the lower part of the riser reactor, and reacts in the riser reactor. The weight ratio of the catalyst A-1 and the raw oil in the reactor is 3:1, the residence time of the raw oil in the riser reactor is 1.6 seconds, and the reaction temperature is 450°C. The pressure of the gas collection chamber is 0.2 MPa. After the oil and gas come out of the riser, they are separated by the cyclone separator and then enter the separation system 14 at the rear. The spent catalyst with carbon enters the stripping section, and the spent catalyst after strippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com