Environmental friendly chromium-free insulating paint

An insulating coating and environmentally friendly technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of affecting corrosion resistance, difficult to mix evenly, easy to produce precipitation, etc., and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

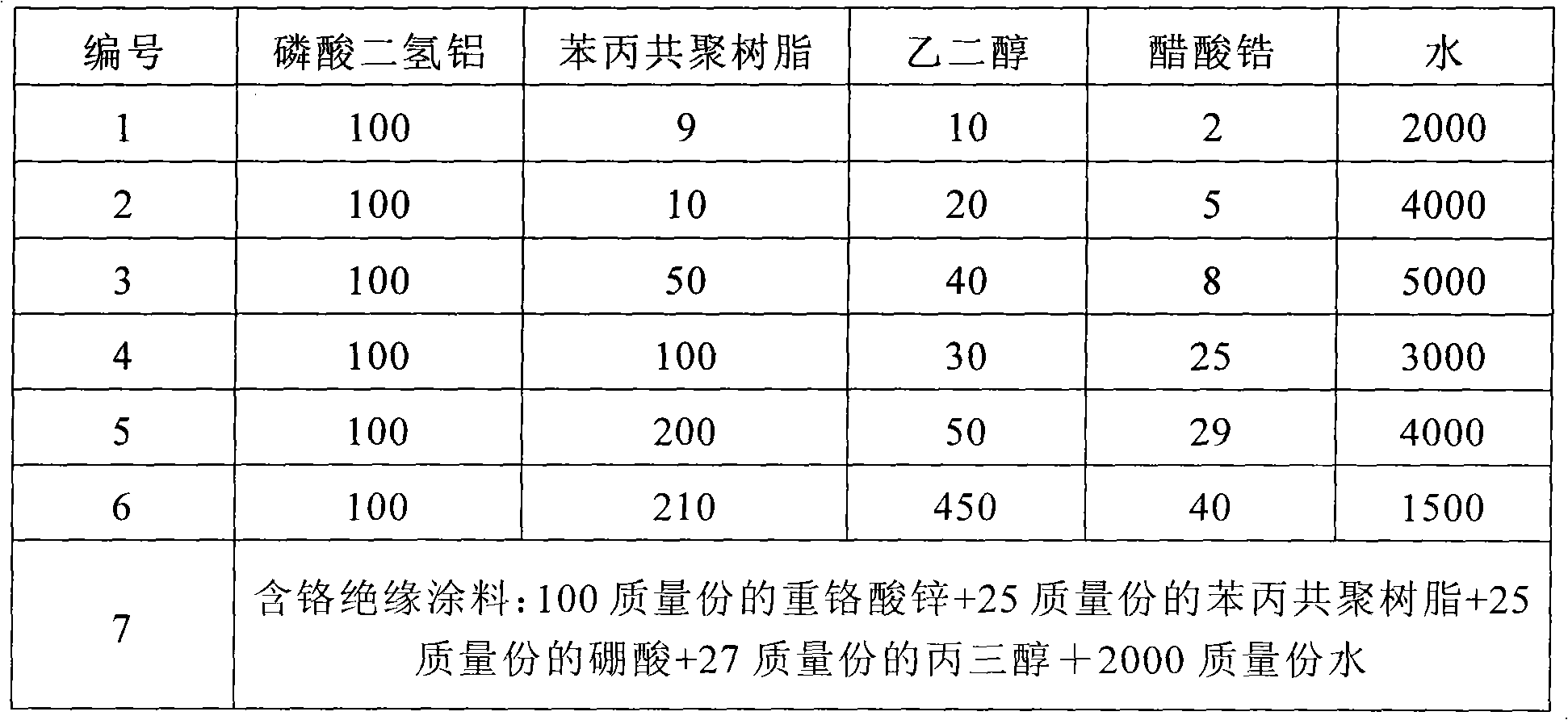

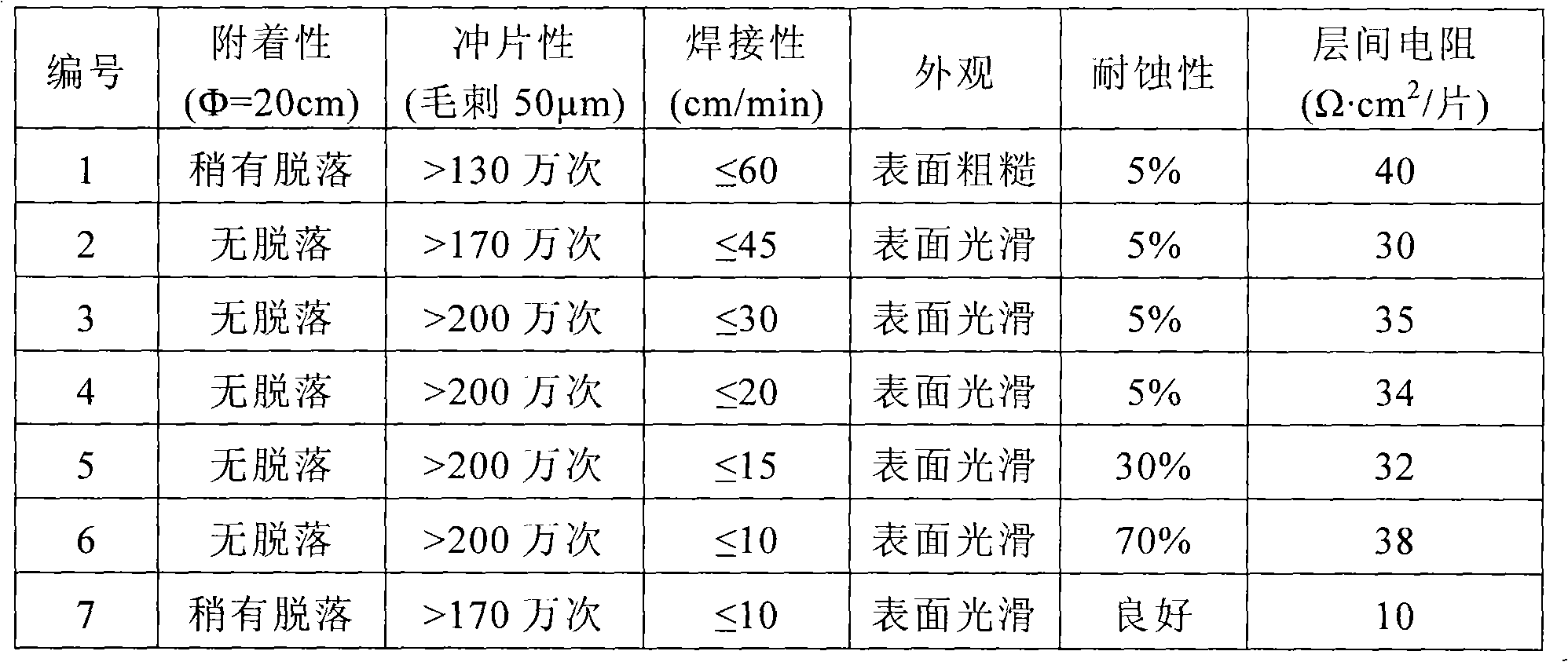

Embodiment 1

[0034] The formula of non-oriented silicon steel chromium-free insulating coating composed of aluminum dihydrogen phosphate, ethylene glycol, acrylic-styrene copolymer resin, zirconium acetate, ethylene glycol and water is shown in Table 1. The formula coating is stirred at a low speed by a magnetic stirring device for 30 minutes at room temperature, and then coated on the surface of a non-oriented silicon steel plate with a thickness of 0.5mm by a roller coater, and the coating amount is kept at 1.8g / m 2 , using an open flame oven, baked into a film at a plate temperature of 200-500 °C. The film performance was tested according to the following conditions, and the coating performance results are shown in Table 2.

[0035] Weldability test conditions: Inert gas tungsten machine shielded welding (TIG), current value 120A, electrode material Th-W, argon gas flow rate 6L / min, pressure 50kg / cm 2 .

[0036] Corrosion resistance test: JIS Z2371 (salt spray test method, Methods of ...

Embodiment 2

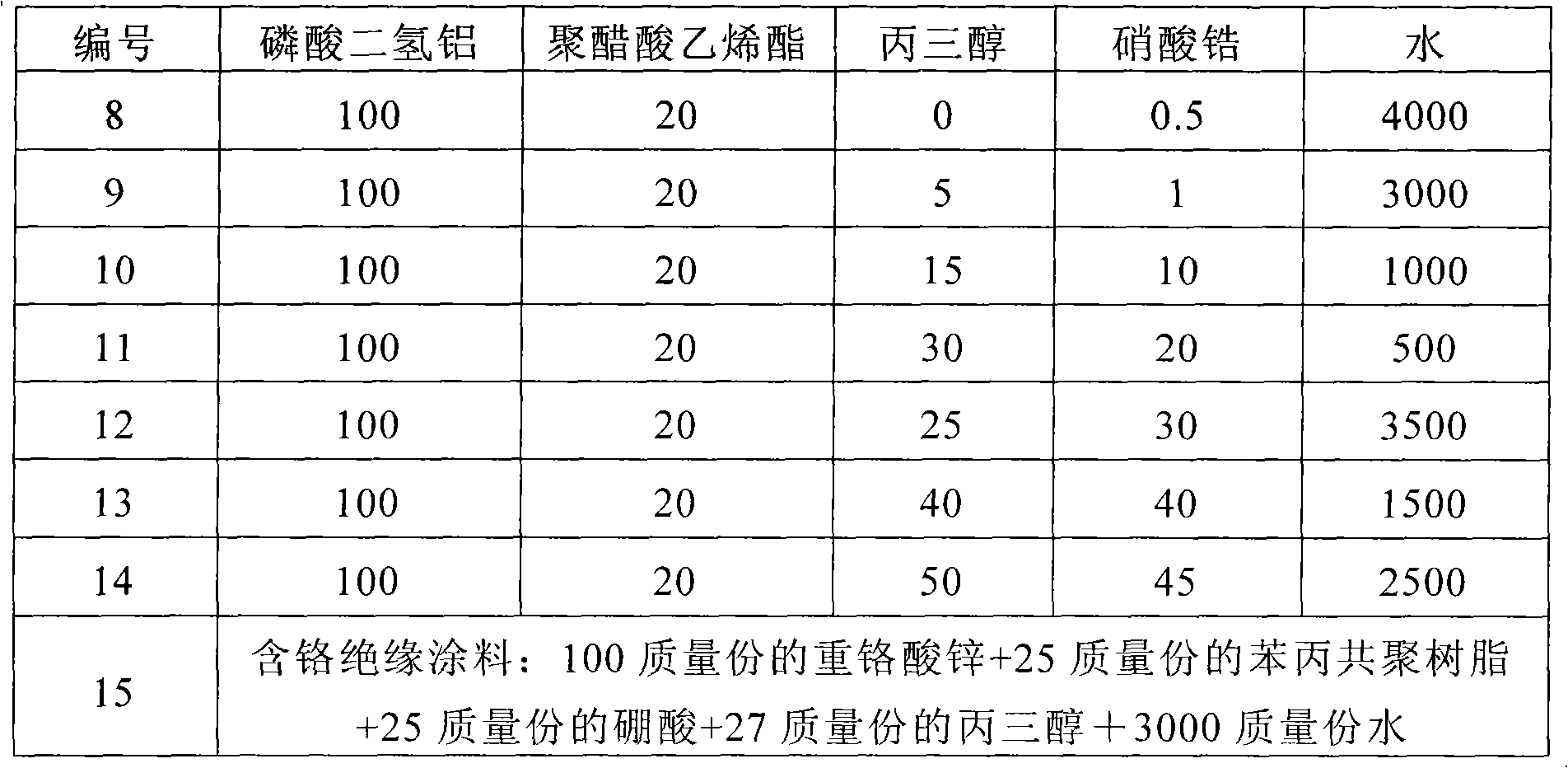

[0046] The formulation of non-oriented silicon steel chromium-free insulating coating composed of aluminum dihydrogen phosphate, polyvinyl acetate, glycerol, zirconium nitrate and water is shown in Table 3. After stirring the formula coating with a magnetic stirring device for 10 minutes at room temperature, it is coated on the surface of a non-oriented silicon steel plate with a thickness of 0.5 mm by a roller coater, and the coating amount is kept at 1.8 g / m 2 , using an open flame oven, baked into a film at a plate temperature of 200-500 °C. The coating performance results are shown in Table 4. The test conditions are as follows:

[0047] P dissolution test: put the coating sample with a fixed area into the wastewater and boil for 10 minutes, then use ICP to test the P dissolved in the wastewater and convert it.

[0048] Sticky surface: Touch the surface with your hands to judge whether there is a sticky feeling.

[0049] All the other test conditions are the same as in ...

Embodiment 3

[0056] Table 5 shows the formulation of non-oriented silicon steel chromium-free insulating coating composed of magnesium dihydrogen phosphate, styrene-acrylic acid copolymer resin, zirconium chloride, ethylene glycol and water. After stirring the formula coating with a magnetic stirring device for 10 minutes at room temperature, it is coated on the surface of a non-oriented silicon steel plate with a thickness of 0.5 mm by a roller coater, and the coating amount is kept at 1.8 g / m 2 , using an open flame oven, baked into a film at a plate temperature of 200-500 °C. The coating performance results are shown in Table 6. The test conditions are the same as in Example 1.

[0057] Table 5 Unit: parts by mass

[0058] Numbering

Magnesium dihydrogen phosphate

Styrene-acrylic copolymer resin

water

16

100

20

0

3

4000

17

100

10

10

2

3000

18

1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com