Light guide plate and backlight module

A light guide plate and light source technology, applied in optics, light guides, light sources, etc., can solve the problems of large color drift over time, reduced luminous efficiency, and low luminous efficiency, and achieve the effect of avoiding the decline of light efficiency and improving light guide efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, for a detailed description as follows:

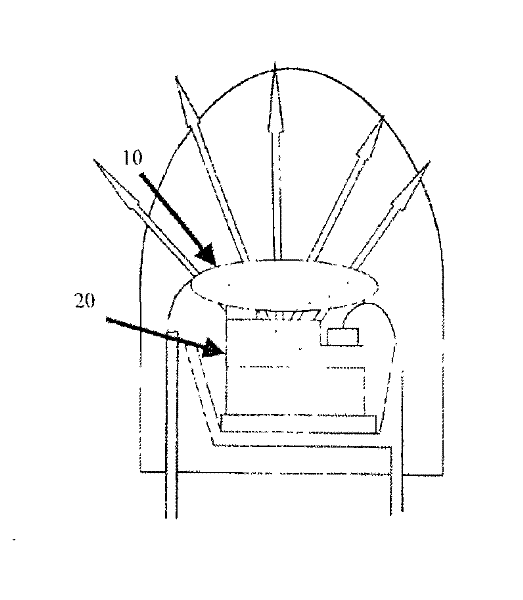

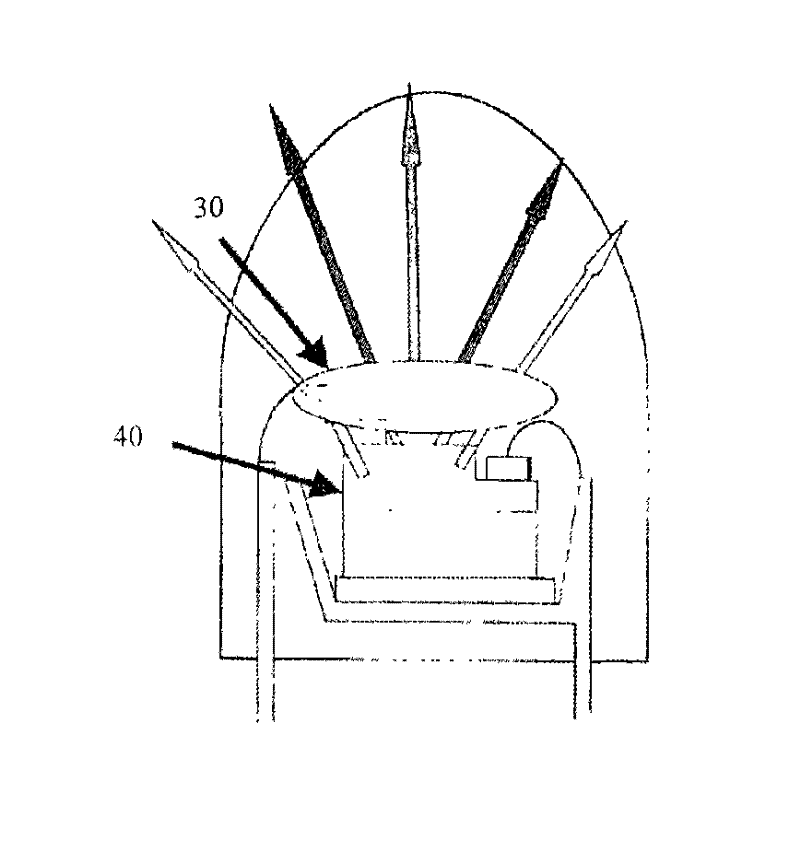

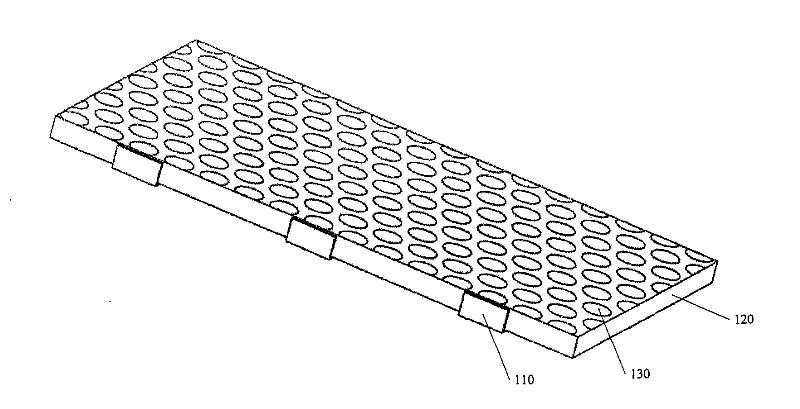

[0025] Such as Figure 4 Shown is a schematic diagram of the overall structure of the edge-lit backlight module in the present invention. The edge-lit backlight module includes several LEDs 210 and a light guide plate 220 . Wherein, the light guide plate 220 includes a bottom surface, a light incident surface and a light exit surface, the light exit surface is opposite to the bottom surface, and the bottom surface includes a plurality of dots 230 . Optionally, the light-emitting surface is connected to the light-incoming surface. The LED 210 is placed on the side of the light guide plate 220 , opposite to the light incident surface, and the light emitted by the LED 210 is incid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com