External combustion regenerative heater

A regenerative heating furnace, external combustion technology, applied in the direction of lighting and heating equipment, furnaces, furnace types, etc., can solve the problem that the regenerative heating furnace is rarely used, and achieve simplified heating process, improved thermal efficiency, and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

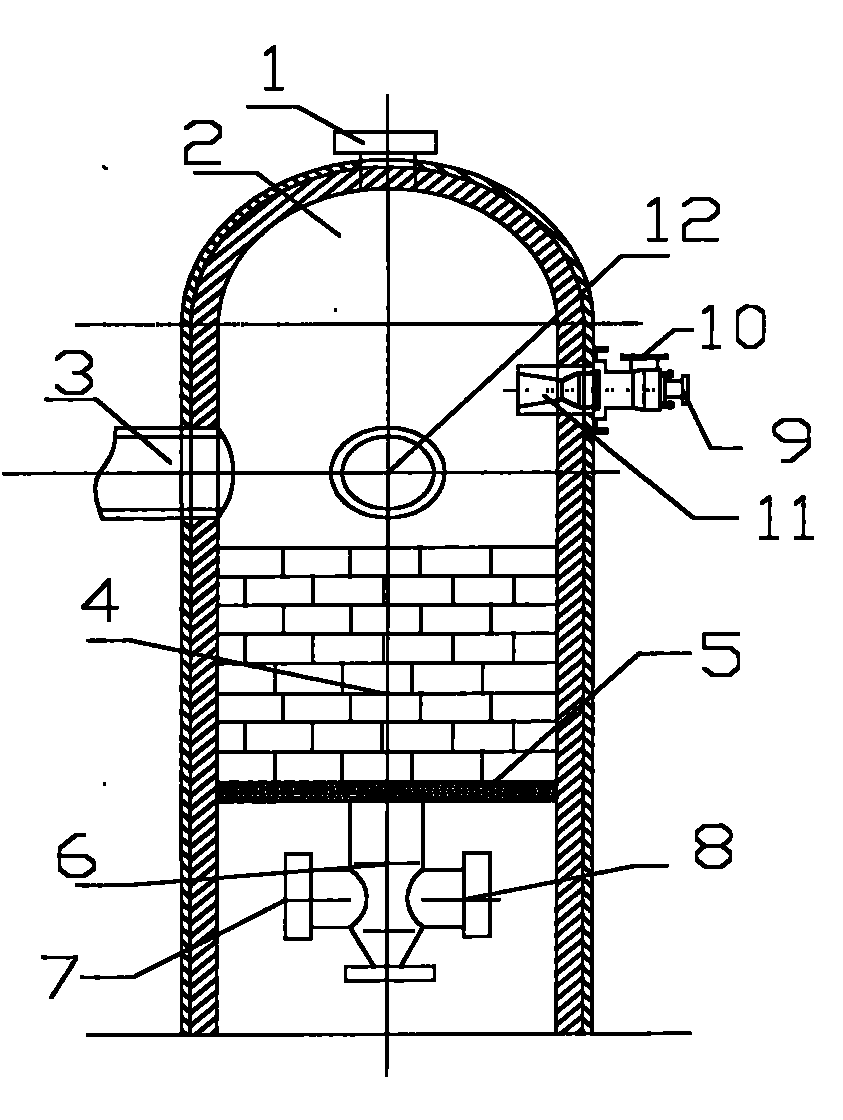

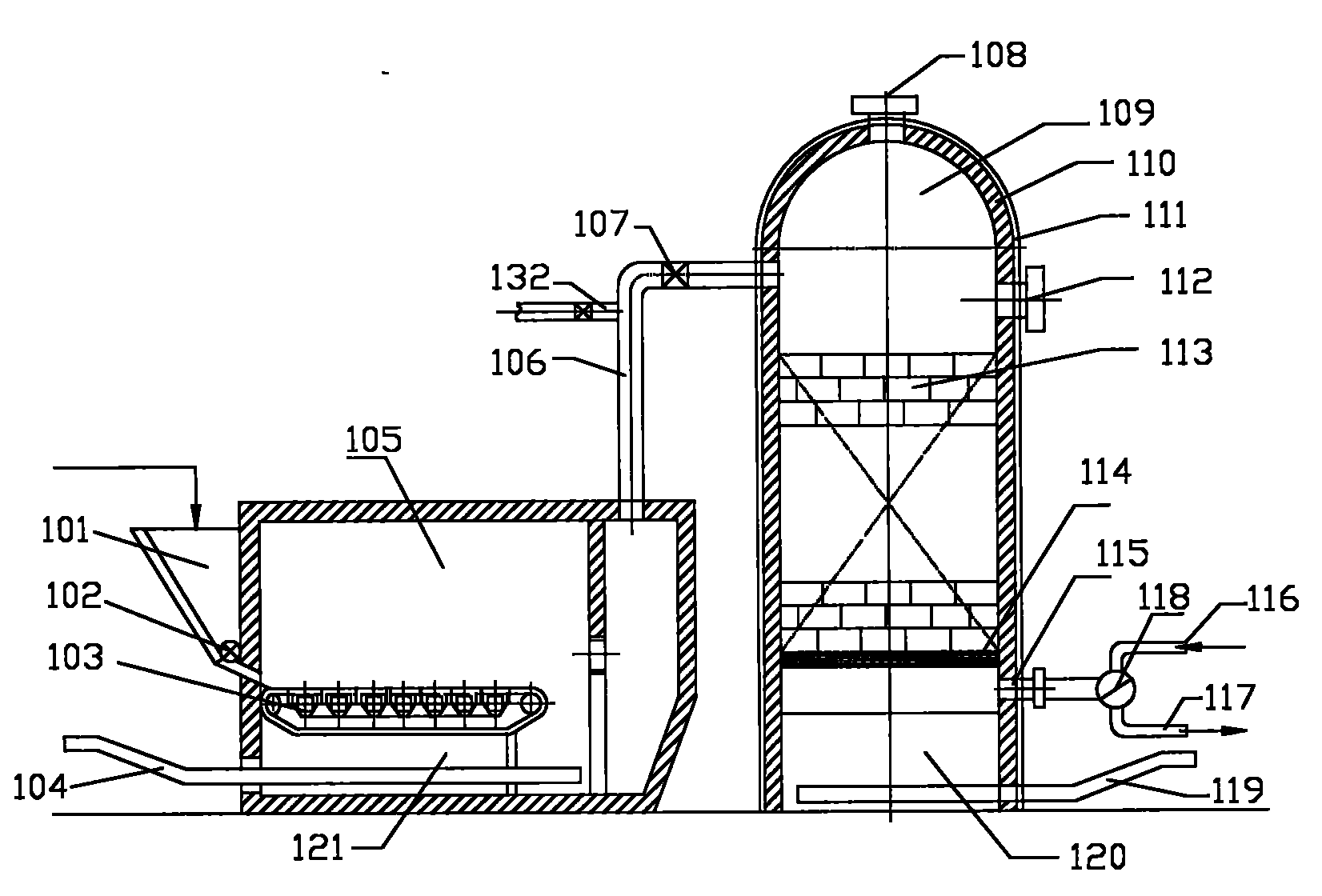

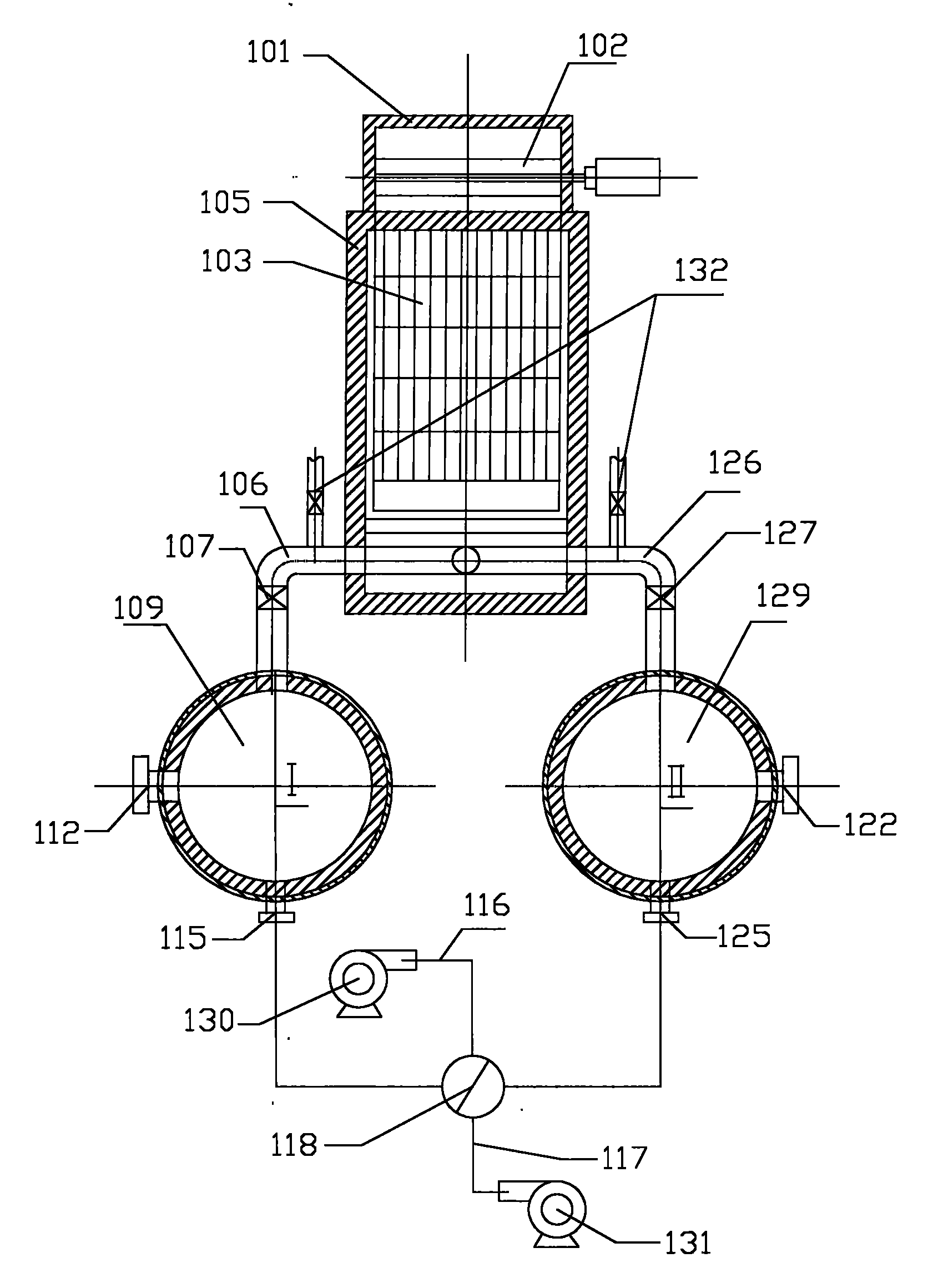

[0020] The working principle and structure of the external combustion type regenerative heating furnace of the present invention are as follows: figure 2 As shown, the structural characteristics of the external combustion regenerative heating furnace can be seen from the figure. The external combustion type regenerative heating furnace 109 is an upright cylinder with a hemispherical top. The inner wall is made of refractory bricks 110, the outside is covered with steel plates 111, and the furnace cavity is filled with checker bricks 113. During production and operation, coal is fed from the hopper 101 arranged above the front side of the dry gas furnace 105, and fed to the chain grate 103 through the feeder 102, and the coal burns on the chain grate to generate high-temperature flue gas, reaching 1100 °C As mentioned above, the high-temperature flue gas is drawn from the upper rear of the dry gas furnace 105 through the discharge pipe 106, and the low-temperature flue gas mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com