Method for preparing tissue engineering frame

A technology for tissue engineering scaffolds and degradable polymers, applied in medical science, prostheses, etc., can solve problems affecting the formation and repair of new tissues, destroying the biological activity of cells and tissues, and the inflammatory response of surrounding tissues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

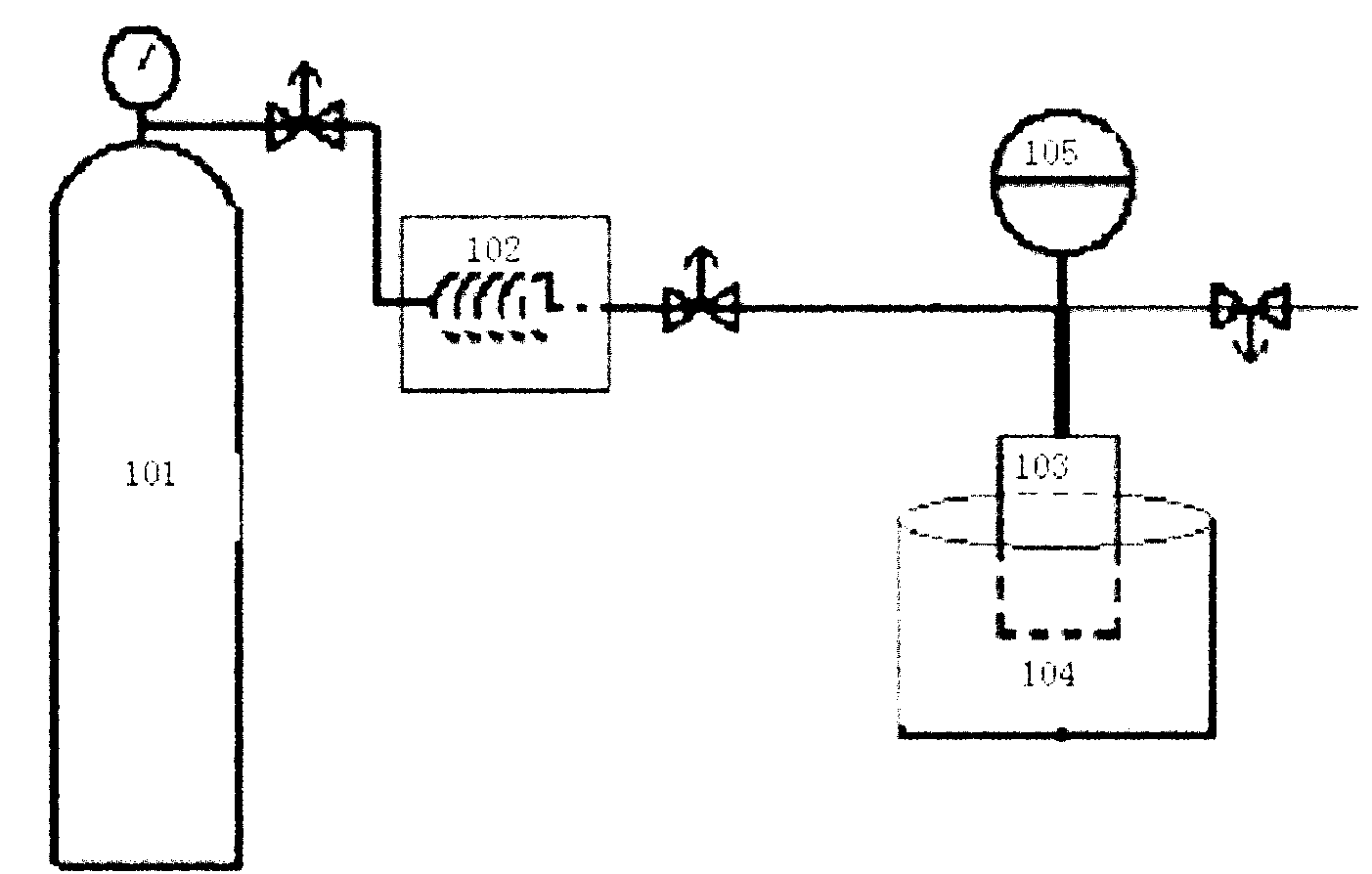

[0034] The embodiment of the present invention discloses a preparation method of a tissue engineering scaffold, comprising:

[0035] Step a) spinning the degradable polymer to obtain degradable polymer fibers;

[0036] Step b) putting the degradable polymer fiber into the tissue engineering scaffold mold, and then putting the tissue engineering scaffold mold equipped with the degradable polymer fiber into supercritical CO with a pressure of 7.38MPa-50MPa 2 Medium treatment, control the treatment temperature at 30-350°C, and then depressurize and discharge CO 2 , removing the tissue engineering scaffold mold to obtain the tissue engineering scaffold.

[0037] The degradable polymers include polylactic acid, polylactic acid derivatives, polylactide glycolide, polylactide glycolide derivatives, polylactic acid and inorganic particle composites, polycaprolactone , polycaprolactone derivatives, polycarbonate and polycarbonate derivatives, when the degradable polymer is several of...

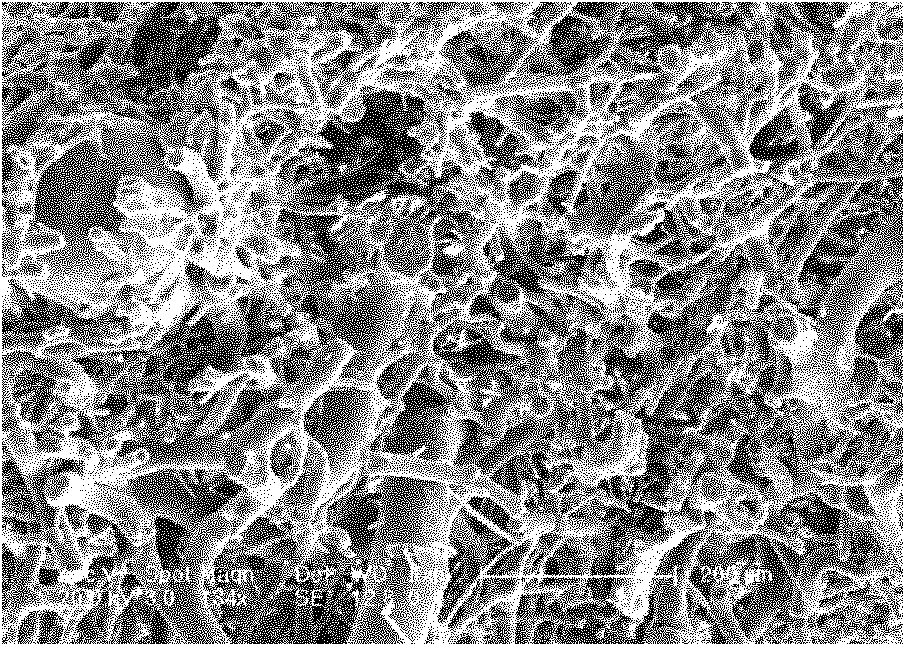

Embodiment 1

[0049] Polylactic acid (PLA) is spun by a melt spinning method to obtain polylactic acid fibers;

[0050] Put the polylactic acid fiber into the hollow tubular mold of the tissue engineering support, then put the hollow tubular mold of the tissue engineering support into the high-pressure reaction kettle 103, put the reaction kettle 103 into the oil bath, and adjust the temperature to a constant temperature of 55 ℃;

[0051] Open the gas valve of the carbon dioxide steel cylinder 101, open the inlet valve of the critical fluid pump 102 and the reactor 103, close the vent valve of the reactor 103, and pass into the supercritical CO in the reactor. 2 , and repeated ventilation 3 times, adjust the supercritical fluid pump output CO 2 Keep the pressure constant to 20MPa, keep the reactor at a constant temperature of 55°C, and keep the constant pressure at 20MPa for 1 hour;

[0052] After the treatment is completed, the CO is decompressed and discharged 2 , the control time is 1...

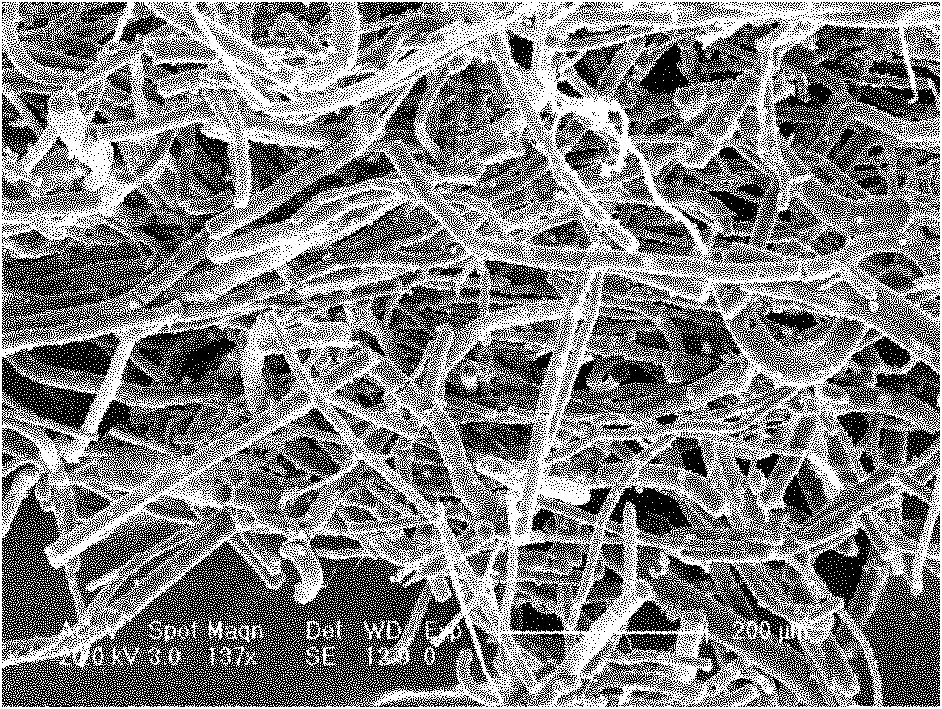

Embodiment 2

[0055] Spinning polylactide glycolide (10% HA / PGLA) grafted with 10% hydroxyapatite by melt spinning;

[0056] Put the product obtained by spinning into the hollow tubular mold of the tissue engineering support, then put the hollow tubular mold of the tissue engineering support into the high-pressure reaction kettle 103, put the reaction kettle 103 into the oil bath, adjust the temperature and constant temperature to 50°C;

[0057] Open the gas valve of the carbon dioxide steel cylinder 101, open the inlet valve of the critical fluid pump 102 and the reactor 103, close the vent valve of the reactor 103, and pass into the supercritical CO in the reactor. 2 , and repeated ventilation 4 times, adjust the supercritical fluid pump output CO 2 Keep the pressure constant to 20MPa, keep the reactor at a constant temperature of 50°C, and keep the constant pressure at 20MPa for 1 hour;

[0058] After the treatment is completed, the CO is decompressed and discharged 2 , the control ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com