Double-sided printed circuit board (PCB) with elements and mutual conductance method thereof

A double-sided, component technology, applied in the field of interconnection and conduction, can solve the problems of consuming large phenolic tree branch cover boards and wood fiber bottom boards, cannot produce boards larger than 762mm, and cannot meet the needs of technological development, etc., to achieve the quality of circuit boards Reliable, reduce chemical wastewater discharge, reduce the effect of chemical treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in more detail below by taking a double-sided flexible printed circuit board as a specific embodiment. It should be understood by those skilled in the art that these embodiments are only some specific examples of the present invention, without any limitation on the present invention and its protection scope. For example, although the embodiments are described below in conjunction with copper foil, the material of the wiring layer not only includes pure copper, but also other copper alloys or other metals or alloys.

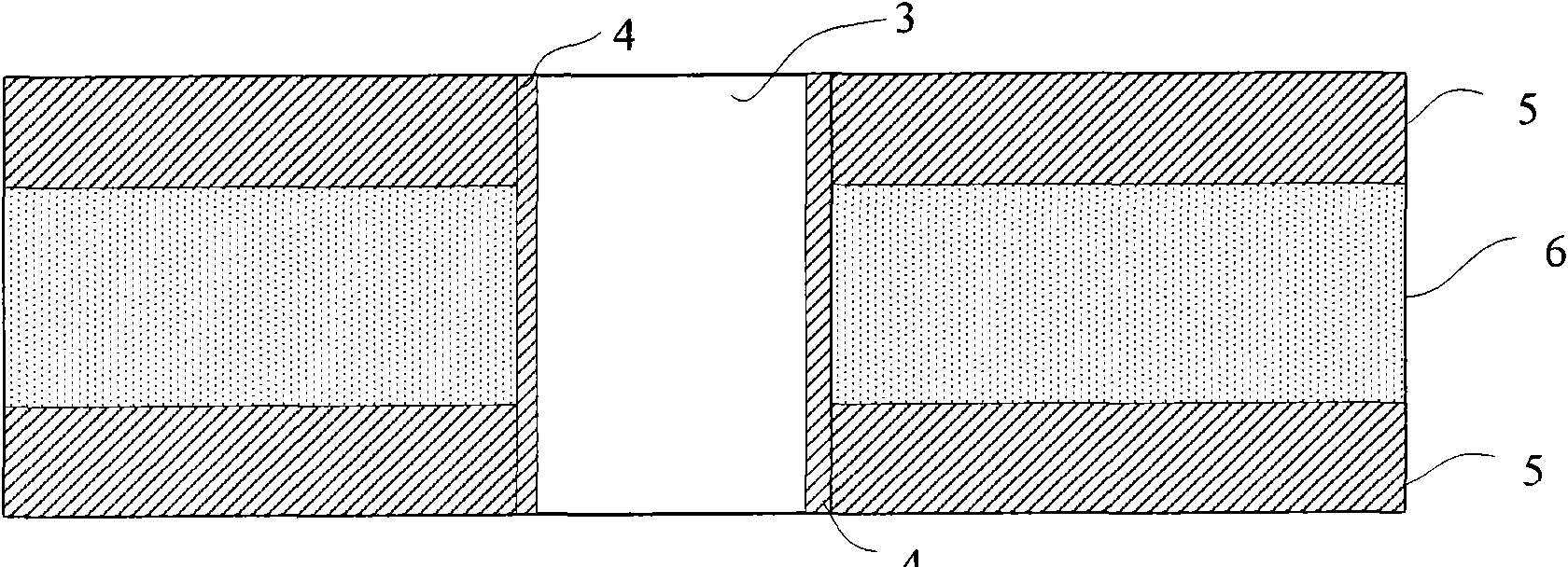

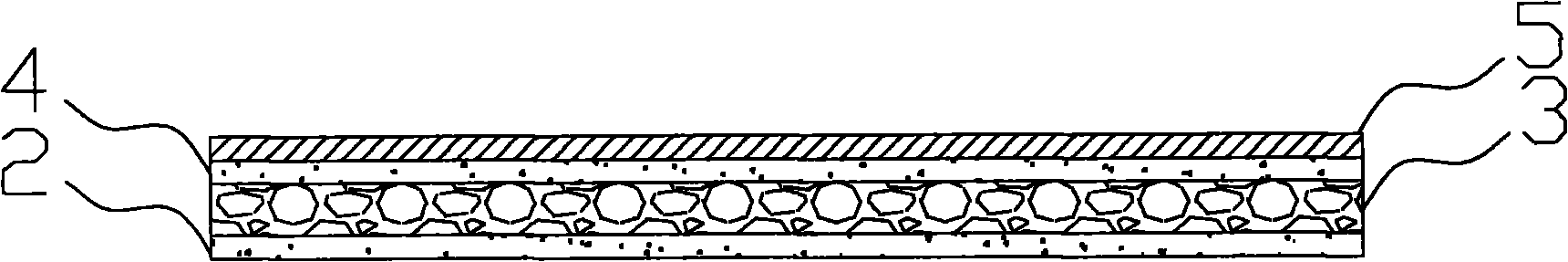

[0060] 1. Production of substrate

[0061] will be like figure 2 The shown rolled copper foil 5 thickness is preferably 12.5-35 microns, the thickness of the adhesive 4 is preferably 12.5-25 microns, and the thickness of the insulating film 3 is preferably 12.5-25 microns. On the film laminating machine, at 120-150 ° C, the pressure is 5-8kg / cm2 and the speed is 0.8-1.0m / min, and the thermosetting adhesive film 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com