Preparation method of activated carbon/metal nitride composite electrode material for supercapacitor

A composite electrode and activated carbon technology, applied in the fields of material science and electrochemical technology science, can solve the problems of low energy density, expensive precious metals, narrow working voltage window, etc., and achieve good comprehensive performance, simple process and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

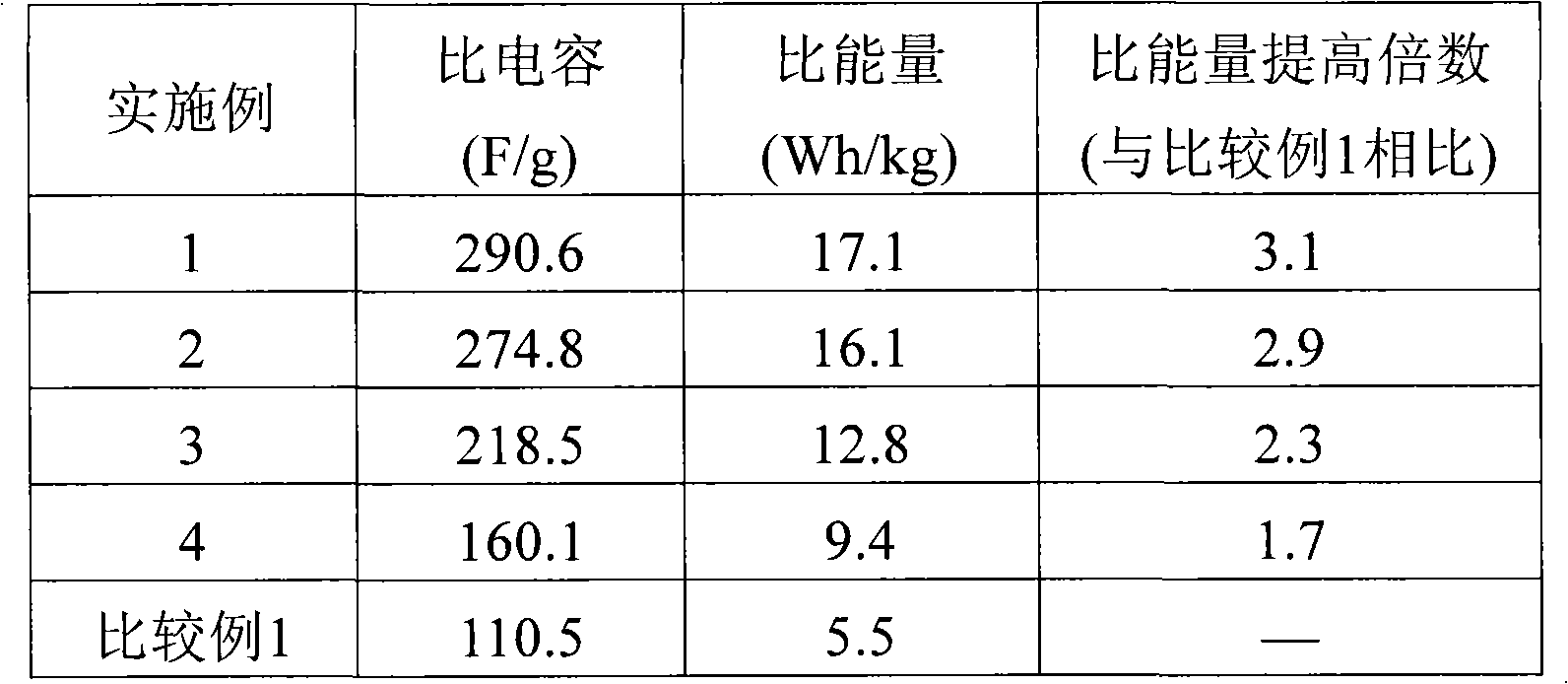

[0025] V at room temperature 2 o 5 Dissolve in deionized water and hydrogen peroxide, prepare 100ml of a solution with a weight concentration of 1wt%, add 1g of activated carbon (commercially available) while stirring, continue stirring for 3h, then oscillate ultrasonically for 24h to form a gel, and dry the sample at 80°C for 24h , the dried sample was placed in a tubular atmosphere furnace, and heated at a rate of 5 °C / min to 600 °C for 5 h in an ammonia atmosphere to obtain an activated carbon electrode material loaded with vanadium nitride. The obtained composite material was mixed with conductive carbon black and PVDF binder in a ratio of 85:10:5, coated on copper foil, punched into pole pieces, and mixed with 1mol / L LiPF 6 / (EC:DMC) is the electrolyte, assembled into a button capacitor, the charge and discharge voltage is 0-3V, and the current density is 0.5A / g. The test results are shown in Table 1.

Embodiment 2

[0027] Butyl titanate (Ti(OC 4 h 9 ) 4 ) was dissolved in absolute ethanol to make a solution with a weight concentration of 1wt%. This solution was added dropwise to a mixed solution of vigorously stirred distilled water and 1g of activated carbon (commercially available), and butyl titanate was hydrolyzed to control titanium dioxide. The molar ratio of butyl acetate to distilled water is 1:150. After the precipitate generated by hydrolysis was filtered, washed twice with distilled water and twice with absolute ethanol, and then dried at 80° C. for 24 h. The sample was placed in a tubular atmosphere furnace and calcined at 5°C / min to 450°C for 4h under the protection of nitrogen, then switched to ammonia gas, heated to 1000°C at 5°C / min, and heat-treated for 5h to obtain titanium nitride-loaded Activated carbon electrode material. The assembly and testing of the button capacitor are the same as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0029] Cr(NO 3 ) 3 9H 2 O was dissolved in absolute ethanol to form a solution with a weight concentration of 1 wt%, and 1 g of activated carbon (commercially available) was added under stirring, and then saturated urea-ethanol solution was added dropwise under stirring to keep the temperature of the solution at about 80 °C , until the final weight ratio of urea nitrate reached 1:9, the mixture was dried at 80°C for 24h, the dried sample was placed in a tubular atmosphere furnace, and the temperature was increased to 5°C / min under an ammonia atmosphere. Heat treatment at 600° C. for 5 h to obtain an activated carbon electrode material loaded with chromium nitride. The assembly and testing of the button capacitor are the same as in Example 1, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com