Air foam slug flow driving process for oil recovery of oil field

An air-foaming and oil-displacing technology, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of poor water injection effect, low oil displacement efficiency, and difficult water injection capacity, etc., so as to improve the sweep efficiency and improve the Oil displacement efficiency, effect of reducing sewage volume and water treatment intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

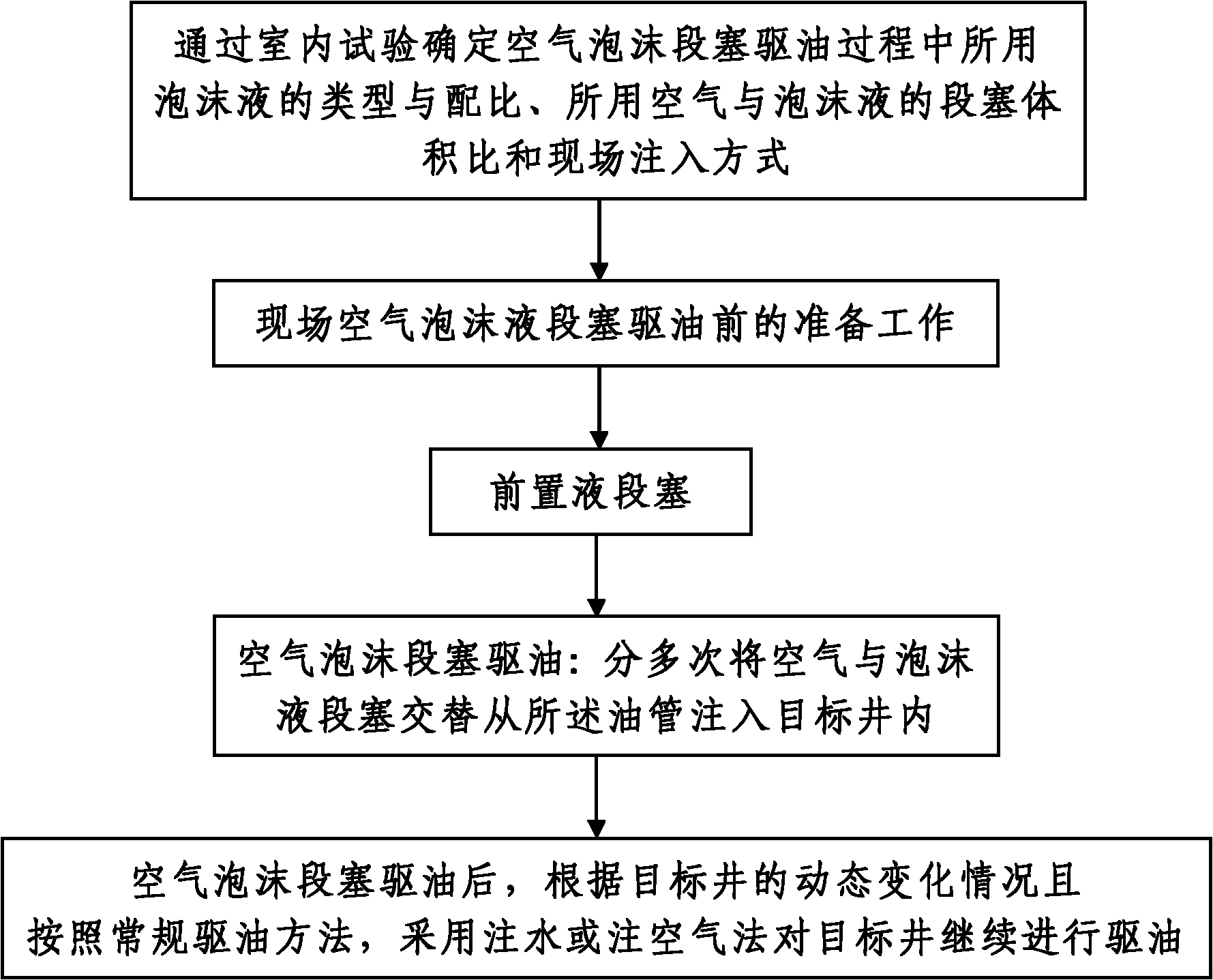

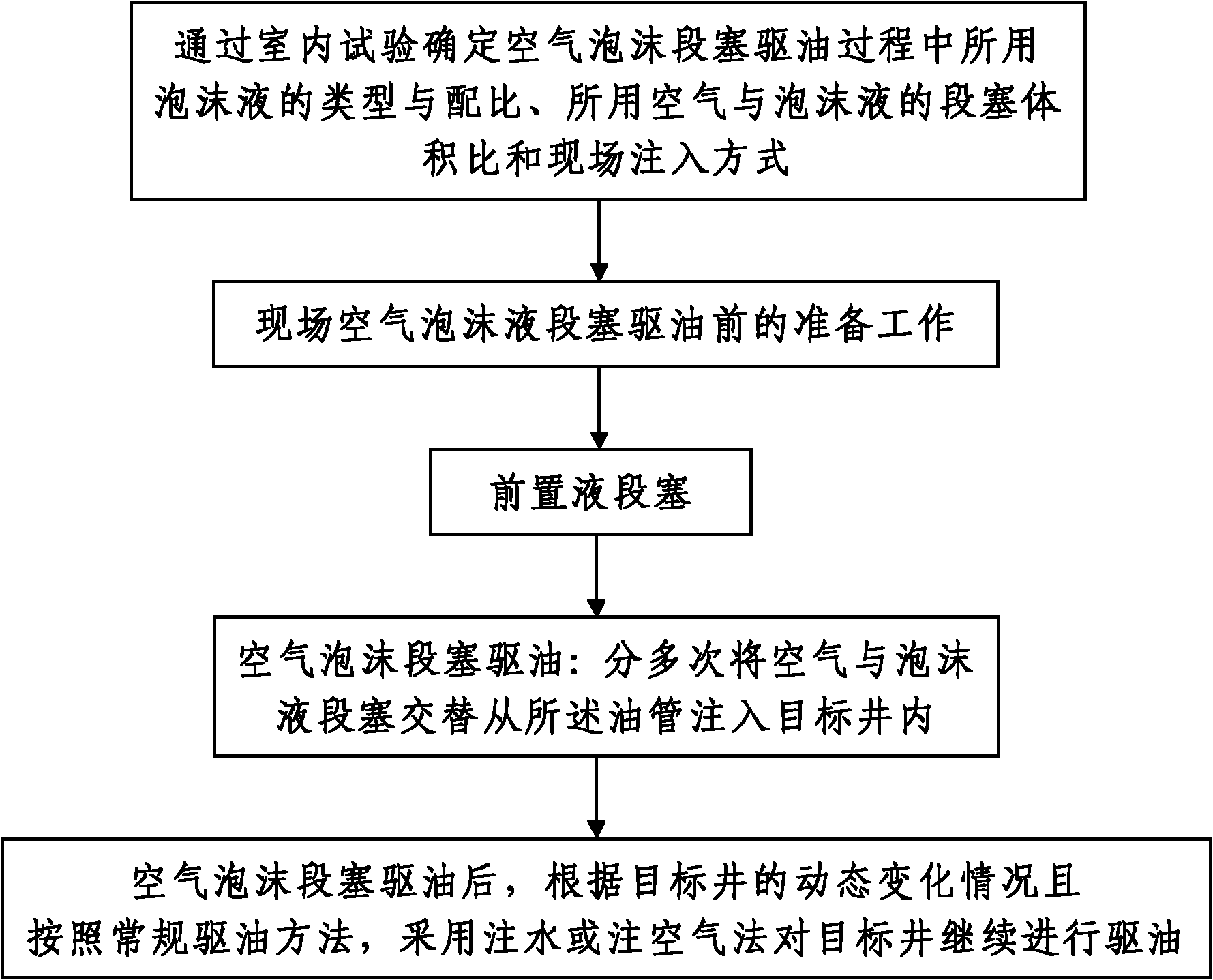

[0049] like figure 1 Shown a kind of air foam slug flooding technology for oil field oil recovery, comprises the following steps:

[0050] Step 1. Determine the type and proportion of foam liquid used in the process of air foam slug flooding, the slug volume ratio of air to foam liquid used in the process of air foam slug flooding, and the field injection method through laboratory tests. The indoor test The determination process is as follows:

[0051] 101. Determine the type and proportion of foam liquid used in air foam slug flooding, and the determination process includes the following steps:

[0052] 1011. According to the conventional foam flooding method, judge and collect various surfactants suitable for foam flooding of the target well.

[0053] 1012. Perform a foaming test on the various surfactants collected in step 1011 according to the conventional foaming test method, so as to test the foaming ability of each surfactant, that is, the foaming height, and record t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com