Organic-inorganic complex dispersion, cell culture substratum manufactured by using the dispersion, and manufacturing methods for same

一种无机复合物、制造方法的技术,应用在一般培养方法、细胞培养支持物/涂层、生物化学设备和方法等方向,能够解决无法细胞回收等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0195] [Preparation of Solution (G) Dissolving Photopolymerization Initiator (D) in Solvent (E)]

[0196] 9.8 g of ethanol as a solvent (E) and 0.2 g of 1-hydroxycyclohexyl phenyl ketone "IRGACURE 184" (manufactured by Ciba-Geigy Corporation) as a water-insoluble photopolymerization initiator (D) were uniformly mixed to prepare a solution (G1).

[0197] [Preparation of reaction solution (F) containing monomer (a), water-swellable clay mineral (B), water-insoluble photopolymerization initiator (D), and aqueous medium (W)]

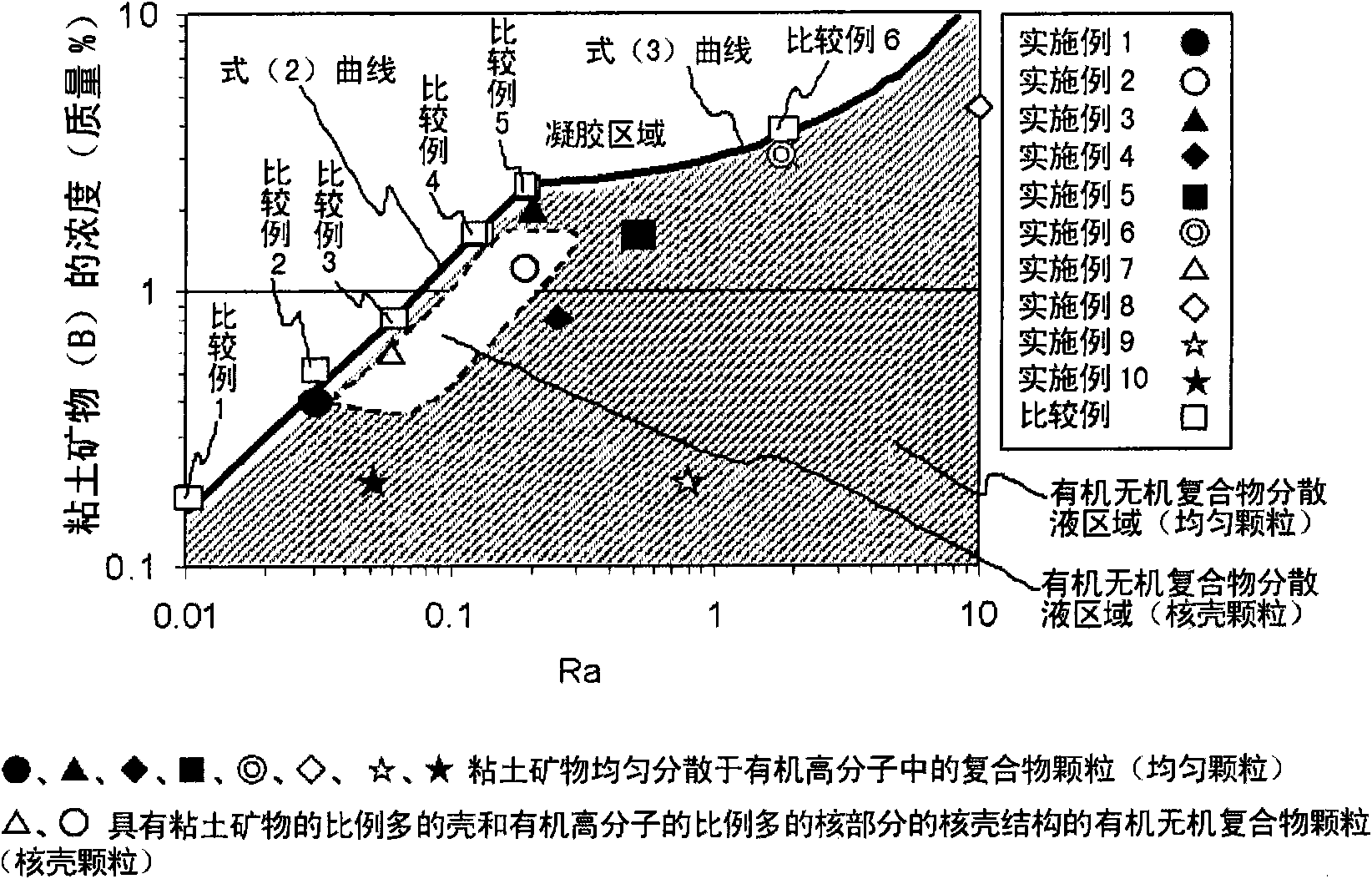

[0198] 1.3 g of 2-methoxyethyl acrylate (manufactured by Toagosei Co., Ltd.) as the monomer (a), and Laponite XLG (manufactured by Rockwood Addtitives Ltd.) as the clay mineral (B), a water-swellable synthetic hector Stone) 0.04 g, 25 μl of a solution (G1) as a water-insoluble photopolymerization initiator (D), and 10 g of water as an aqueous medium (W) were uniformly mixed to prepare a reaction liquid (F1).

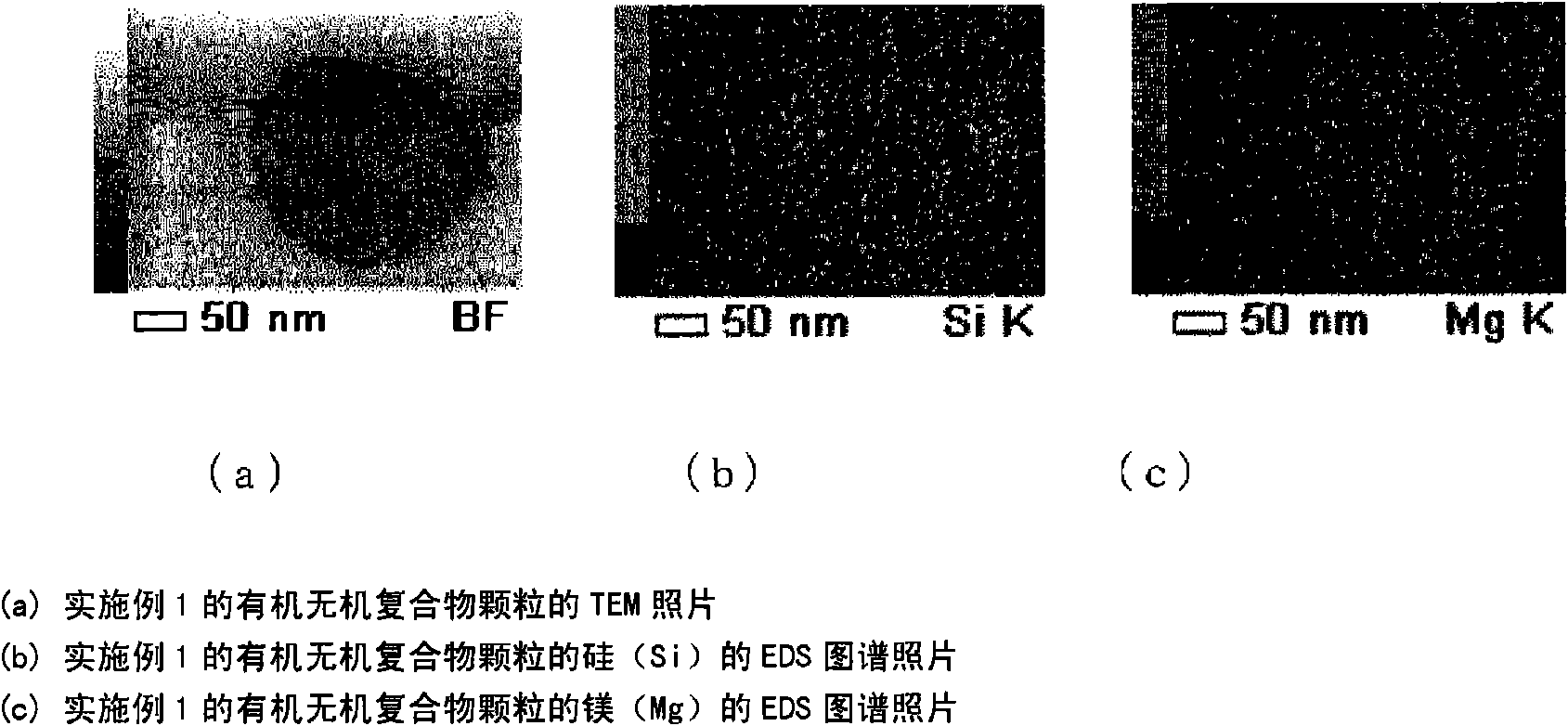

[0199] [Preparation of organic-inorganic compo...

Embodiment 2

[0206] [Preparation of reaction solution (F) containing monomer (a), water-swellable clay mineral (B), water-insoluble photopolymerization initiator (D), and aqueous medium (W)]

[0207] 0.64 g of 2-methoxyethyl acrylate (manufactured by Toagosei Co., Ltd.) as the monomer (a), 0.12 g of Laponite XLG (manufactured by Rockwood Addtitives Ltd.) as the clay mineral (B), and 0.12 g as the water-insoluble 25 μl of a solution (G1) of a photopolymerization initiator (D) and 10 g of water as an aqueous medium (W) were uniformly mixed to prepare a reaction solution (F2).

[0208] [Preparation of organic-inorganic composite dispersion]

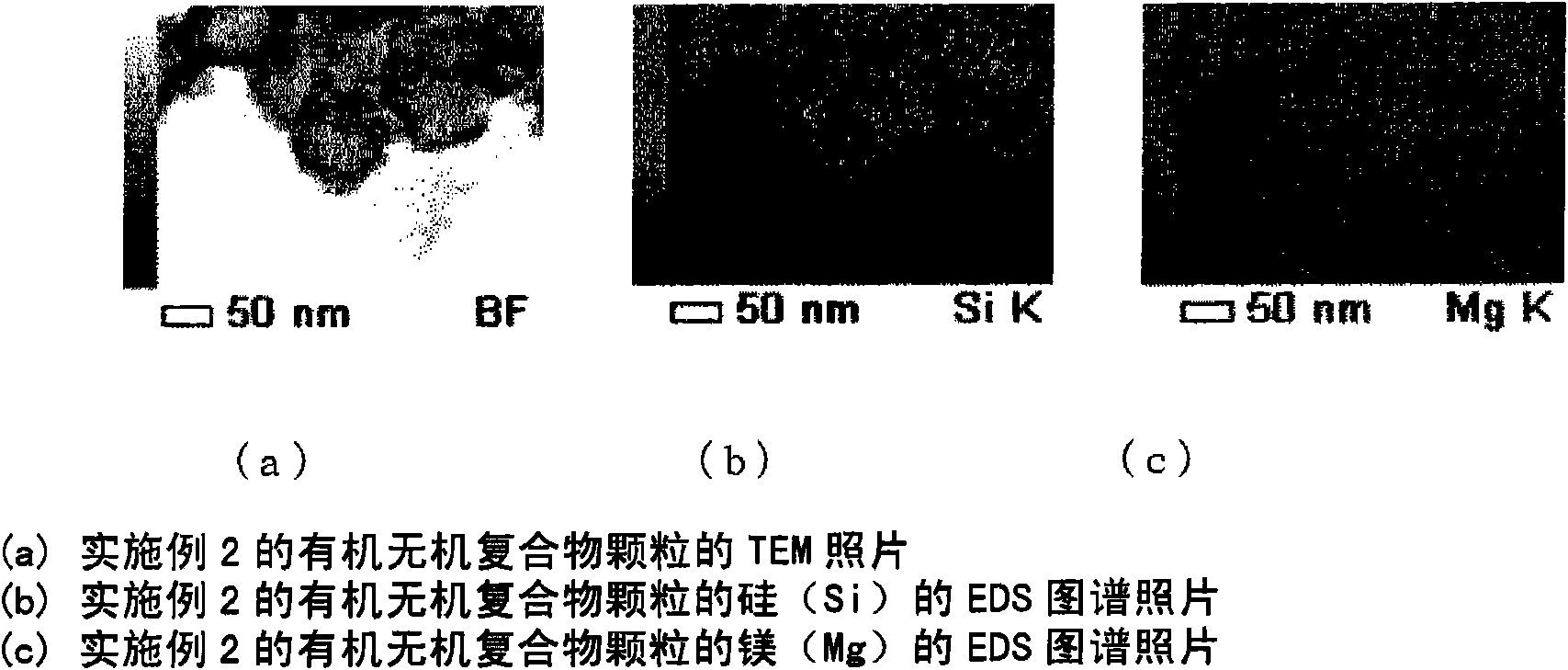

[0209] While stirring the above reaction solution (F2) with a magnetic stirrer, the intensity of ultraviolet light at 365nm for 180 seconds was 40mW / cm 2 Ultraviolet rays are used to prepare a slightly opalescent organic-inorganic composite dispersion (MNC1.5M0.5).

[0210] The particle size distribution of the organic-inorganic composite dispersion (M...

Embodiment 3

[0214] [Preparation of reaction solution (F) containing monomer (a), water-swellable clay mineral (B), water-insoluble photopolymerization initiator (D), and aqueous medium (W)]

[0215] 1.0 g of 2-methoxyethyl acrylate (manufactured by Toagosei Co., Ltd.) as the monomer (a), 0.2 g of Laponite XL G (manufactured by Rockwood Addtitives Ltd.) as the clay mineral (B), and 0.2 g as the non-water-soluble 25 μl of the solution (G1) of the photopolymerization initiator (D) and 10 g of water as the aqueous medium (W) were uniformly mixed to prepare a reaction solution (F3).

[0216] [Preparation of organic-inorganic composite dispersion]

[0217] While stirring the above reaction solution (F3) with a magnetic stirrer, the intensity of ultraviolet light at 365nm for 180 seconds was 40mW / cm 2 Ultraviolet rays are used to prepare a slightly opalescent organic-inorganic composite dispersion (MNC2.5M0.8).

[0218] The particle size distribution of the organic-inorganic composite dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com