Method for synthesizing methyl isopropyl ketone

A kind of technology of methyl isopropyl ketone and synthesis method, applied in the field of synthesis of methyl isopropyl ketone, can solve the problems of low conversion rate of raw materials, large pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

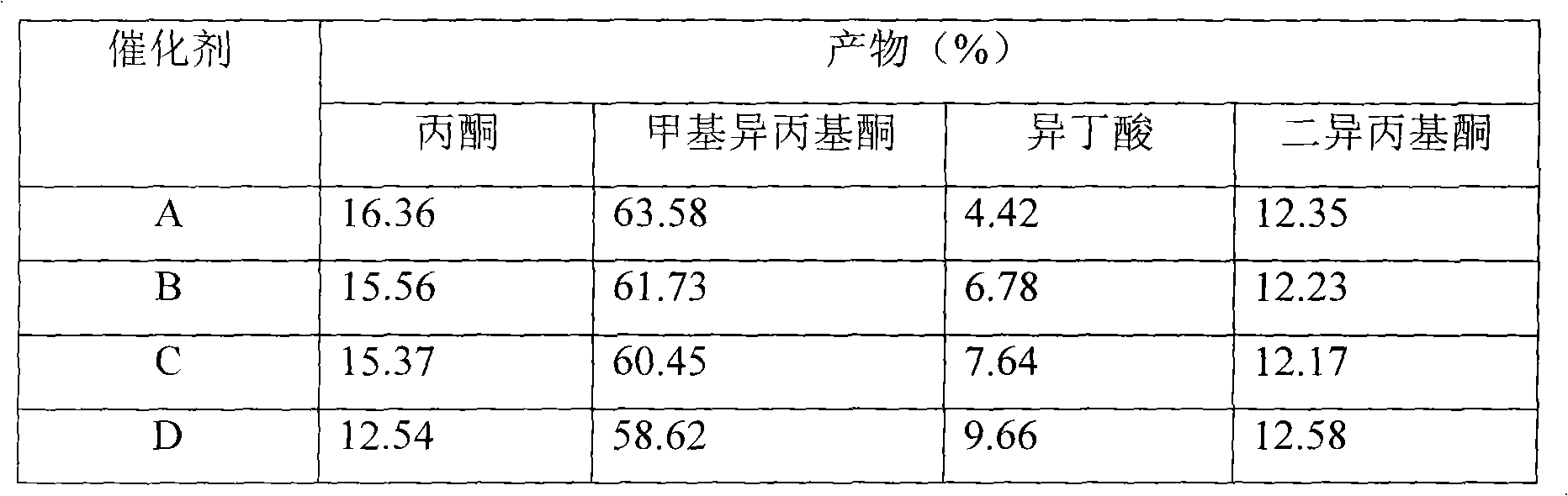

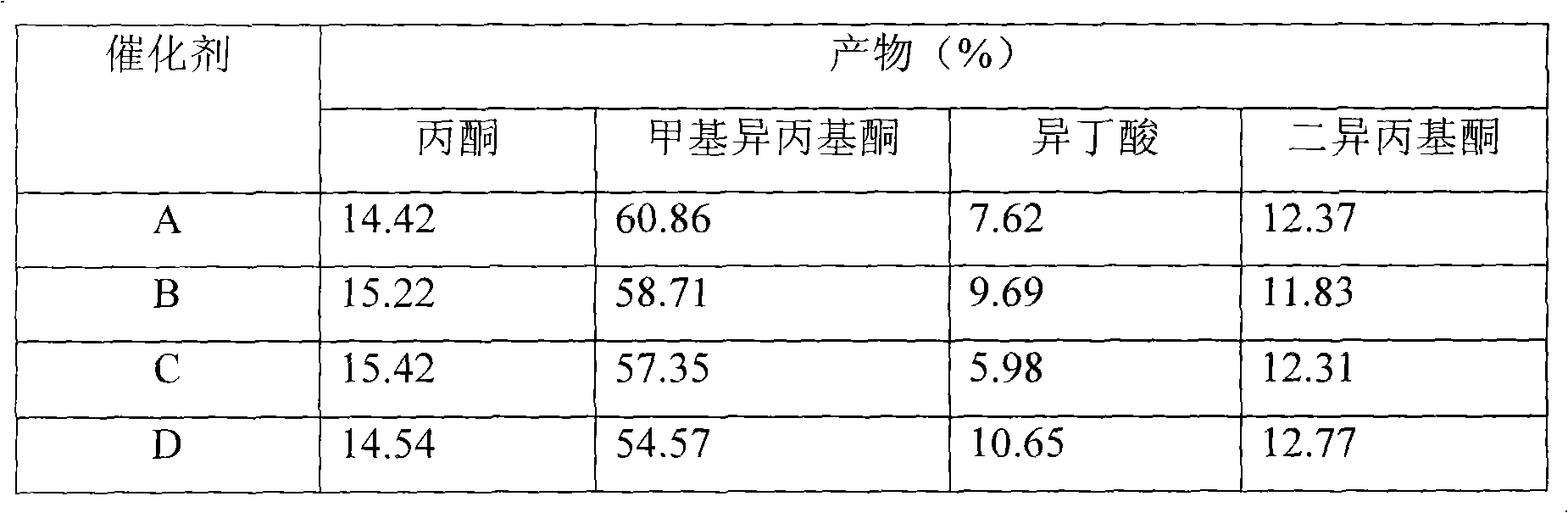

Embodiment 1

[0010] Weigh 22.69 grams of lanthanum nitrate solid and place it in a beaker, add 15 ml of distilled water to dissolve it, then weigh 42 grams of titanium-aluminum composite carrier and add it to the above solution, soak at room temperature for 6 hours, dry in an oven at 120 °C for 4 hours, and finally Catalyst A was obtained by calcining in a muffle furnace at 550°C for 5 hours.

Embodiment 2

[0012] Weigh 15.56 grams of lanthanum nitrate solid and place it in a beaker, add 15 ml of distilled water to dissolve it, then weigh 42 grams of titanium-aluminum composite carrier and add it to the above solution, soak for 6 hours at room temperature, dry in an oven at 120 °C for 4 hours, and finally Catalyst B was obtained by calcining in a muffle furnace at 550°C for 5 hours.

Embodiment 3

[0014] Weigh 22.69 grams of lanthanum nitrate solid and place it in a beaker, add 32 ml of distilled water to dissolve it, then weigh 42 grams of alumina carrier and add it to the above solution, soak it at room temperature for 6 hours, dry it in an oven at 120 ° C for 4 hours, and finally 550 ℃ in a muffle furnace for 5 hours to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com