Method for manufacturing self-alignment metal interconnection wire

A technology of metal interconnection lines and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of small minimum distances between metal interconnection lines and gate conductive layers and gate layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

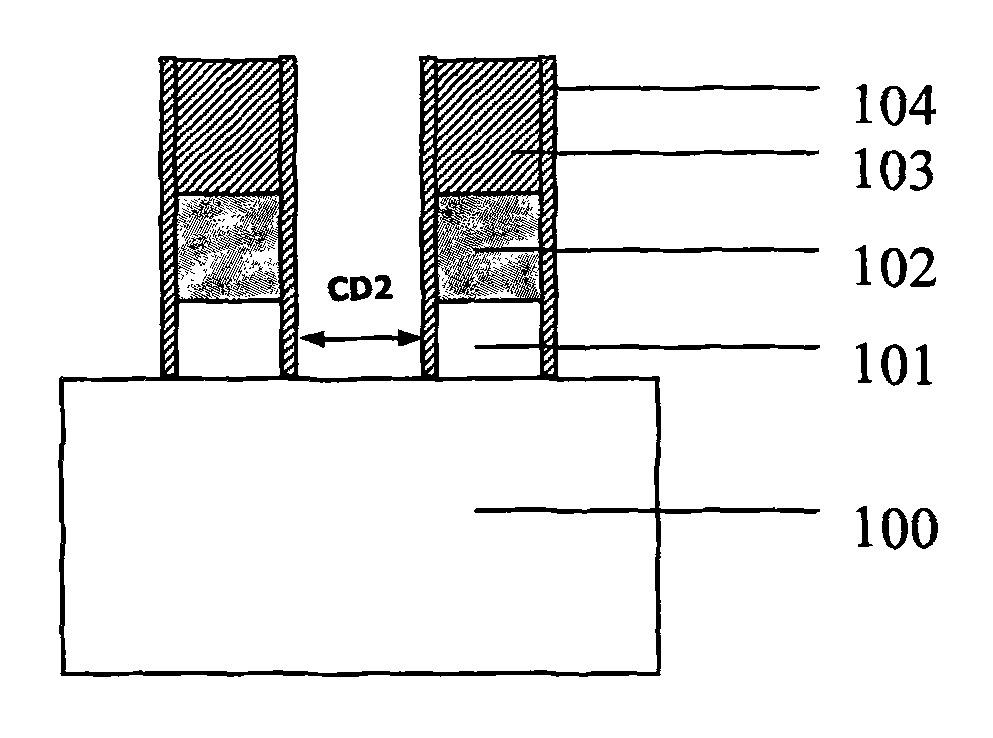

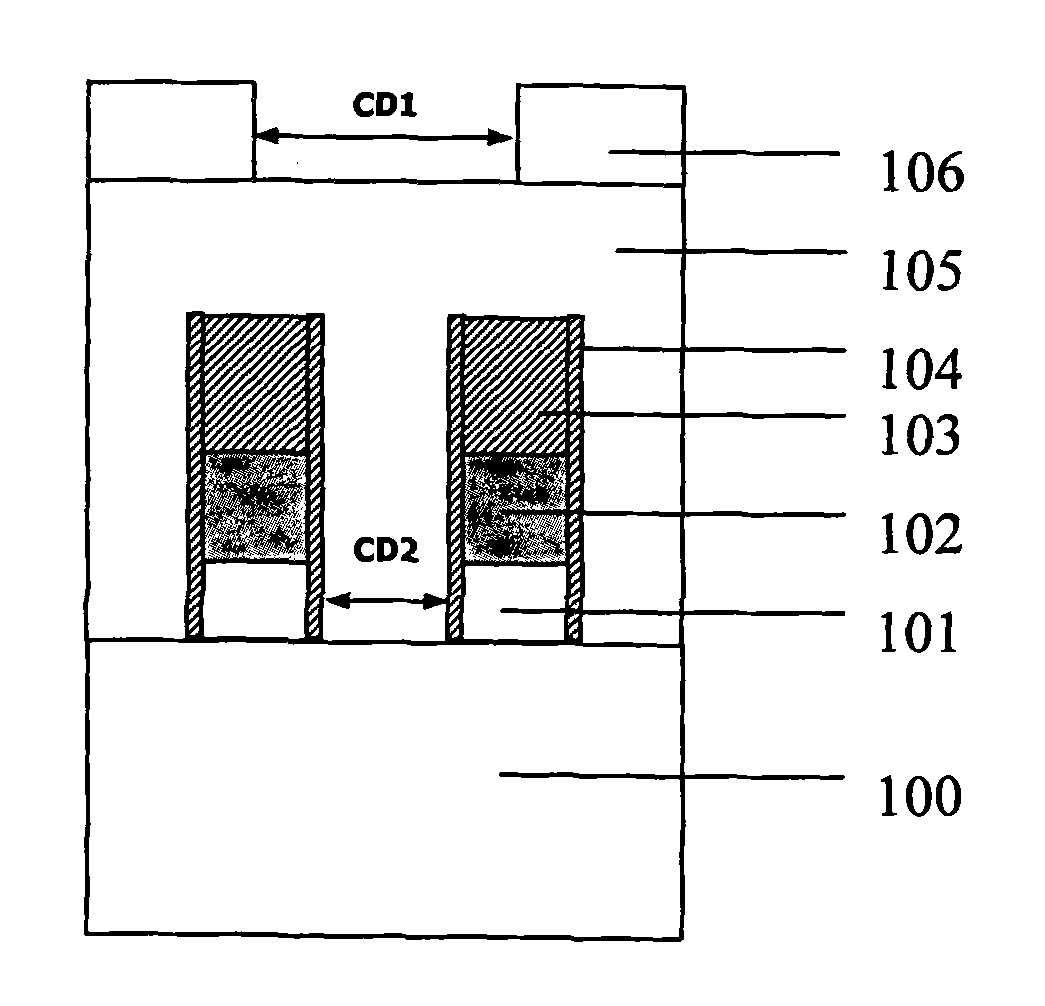

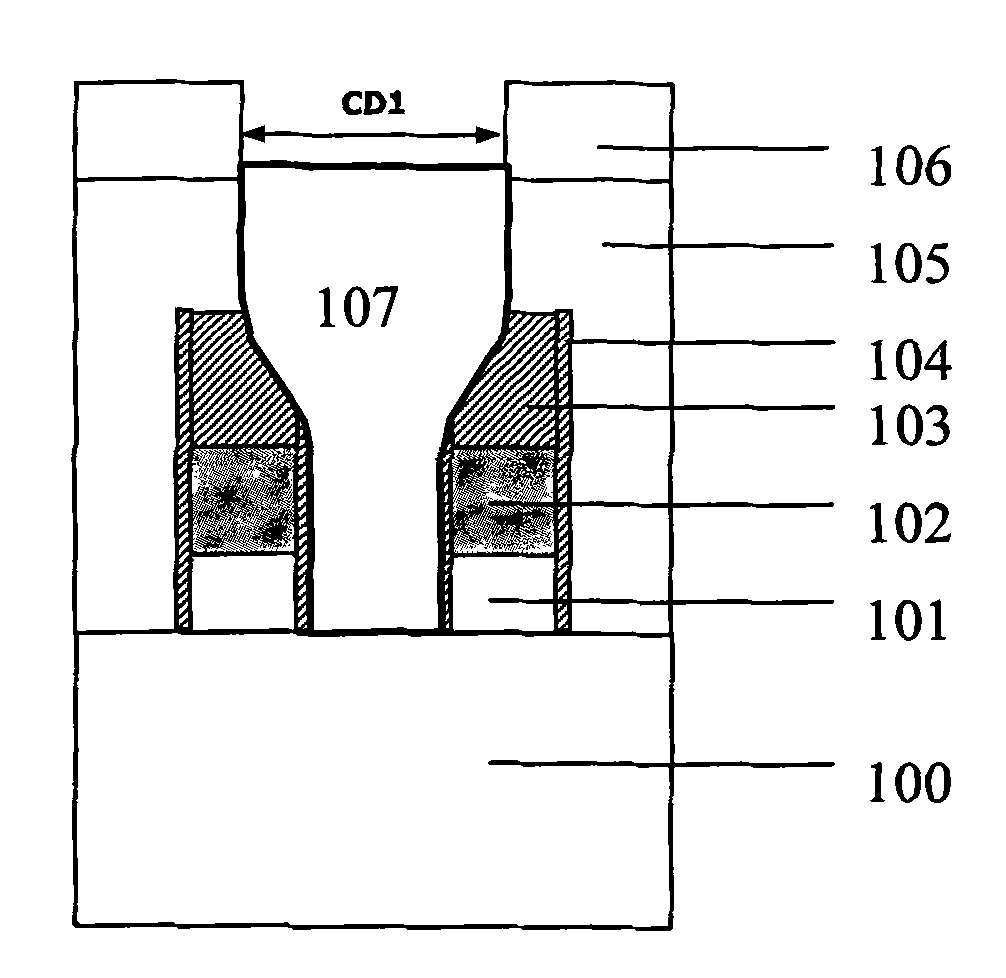

[0030] The method for manufacturing the self-aligned metal interconnection in this embodiment firstly provides a semiconductor substrate with more than one gate structure, and the gate structure consists of a gate layer, a gate conductive layer and a first hard mask sequentially located on the semiconductor substrate. Layer composition, and then form a first photoresist layer with a surface height higher than the gate structure on the semiconductor substrate and the gate structure; then plasma etch the first photoresist layer to expose the first mask layer and a part of the gate conductive layer; etching the exposed part of the gate conductive layer to cause a recess; removing the first photoresist layer; forming sidewalls on both sides of the gate structure; through the above process, the first mask layer and the gate conductive layer, the spacer will fill the recess produced by etching the gate conductive layer, therefore, the thickness of the sidewall at the interface positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com