Particle magnesium desulfurizer/particle magnesium alloy desulfurizer based on magnesium, magnesium alloy and waste materials thereof and preparation method

A magnesium alloy and desulfurizer technology, applied in the field of granular magnesium desulfurizer/granular magnesium alloy desulfurizer and preparation, can solve the problems of high production cost, poor fluidity, resource waste, etc., reduce energy consumption costs, promote steel production and Quality, the effect of preventing the penetration of atmospheric moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

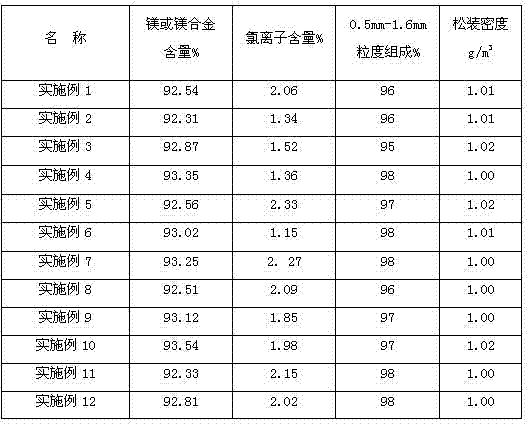

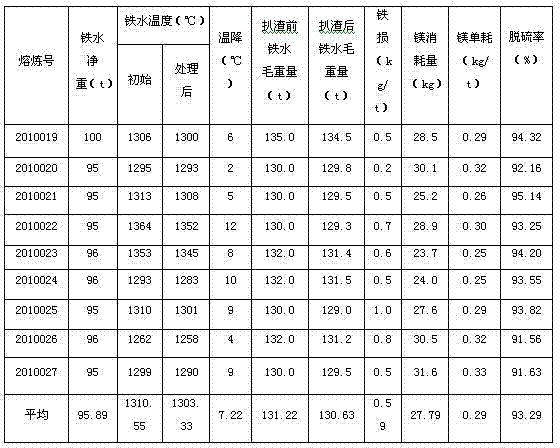

[0059] Combining diagrams and tables

[0060] A. A granular magnesium desulfurizer / granular magnesium alloy desulfurizer based on magnesium, magnesium alloys and waste materials thereof, the composition of which is composed of 93% of magnesium melt or magnesium alloy melt and 7% of salt melt, wherein the salt melt Liquid components and content (weight percentage) are: sodium chloride 50%-65%, potassium chloride 30%-45%, magnesium chloride 2%-5%;

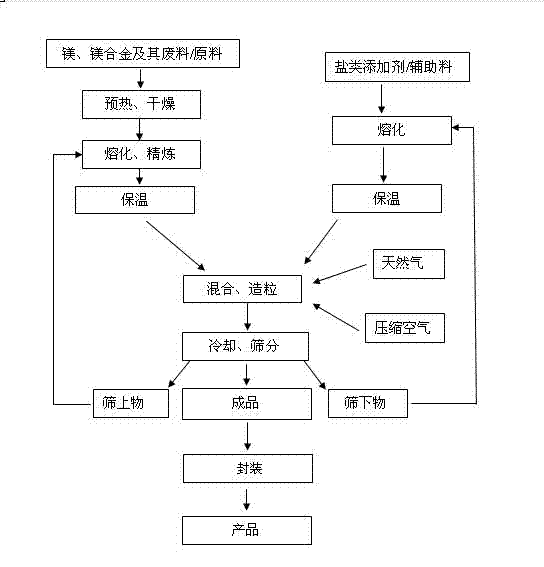

[0061] B, prepare a kind of technique and operation of granular magnesium desulfurizer / granular magnesium alloy desulfurizer based on magnesium, magnesium alloy and waste thereof:

[0062] Ⅰ. Process flow

[0063] Magnesium, magnesium alloy and its scrap / raw material—preheating, drying—melting, refining—insulation and salt additives / auxiliary materials—melting—insulation / remixing, granulation—cooling, screening—finished product—packaging—product;

[0064] Ⅱ. Composition operation steps

[0065] ① Select regular magnesium, magnesiu...

Embodiment 1

[0077] A, a granular magnesium desulfurizer based on magnesium and magnesium waste, its composition is composed of 93% magnesium melt and 7% salt melt, wherein the salt melt components and content (weight percentage) are: chlorine Sodium chloride 50%, potassium chloride 45%, magnesium chloride 5%;

[0078] B, prepare a kind of technique and operation based on the granular magnesium desulfurizer of magnesium, magnesium waste:

[0079] Ⅰ. Process flow

[0080] Magnesium, magnesium waste / raw material—preheating, drying—melting, refining—insulation and salt additives / auxiliary materials—melting—insulation / remixing, granulation—cooling, screening—finished product—packaging—product;

[0081] Ⅱ. Composition operation steps

[0082] ① Choose regular magnesium and magnesium waste as raw materials according to the requirements of the ratio, and salt additives as auxiliary materials, and set aside;

[0083] ②Put the raw materials into the preheating oven to preheat, dry and set aside;...

Embodiment 2

[0094] A, a granular magnesium desulfurizer based on magnesium and magnesium waste, its composition is composed of 93% magnesium melt and 7% salt melt, wherein the salt melt components and content (weight percentage) are: chlorine Sodium chloride 53%, potassium chloride 43%, magnesium chloride 4%;

[0095] B, prepare a kind of technique and operation based on the granular magnesium desulfurizer of magnesium, magnesium waste:

[0096] Ⅰ. Process flow

[0097] Magnesium, magnesium waste / raw material—preheating, drying—melting, refining—insulation and salt additives / auxiliary materials—melting—insulation / remixing, granulation—cooling, screening—finished product—packaging—product;

[0098] Ⅱ. Composition operation steps

[0099] ① Choose regular magnesium and magnesium waste as raw materials according to the requirements of the ratio, and salt additives as auxiliary materials, and set aside;

[0100] ②Put the raw materials into the preheating oven to preheat, dry and set aside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com