Electrophoretic chip for optical detection and electrophoretic device thereof

An electrophoretic chip and optical detection technology, which is applied in the direction of fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of complexity and difficulty in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

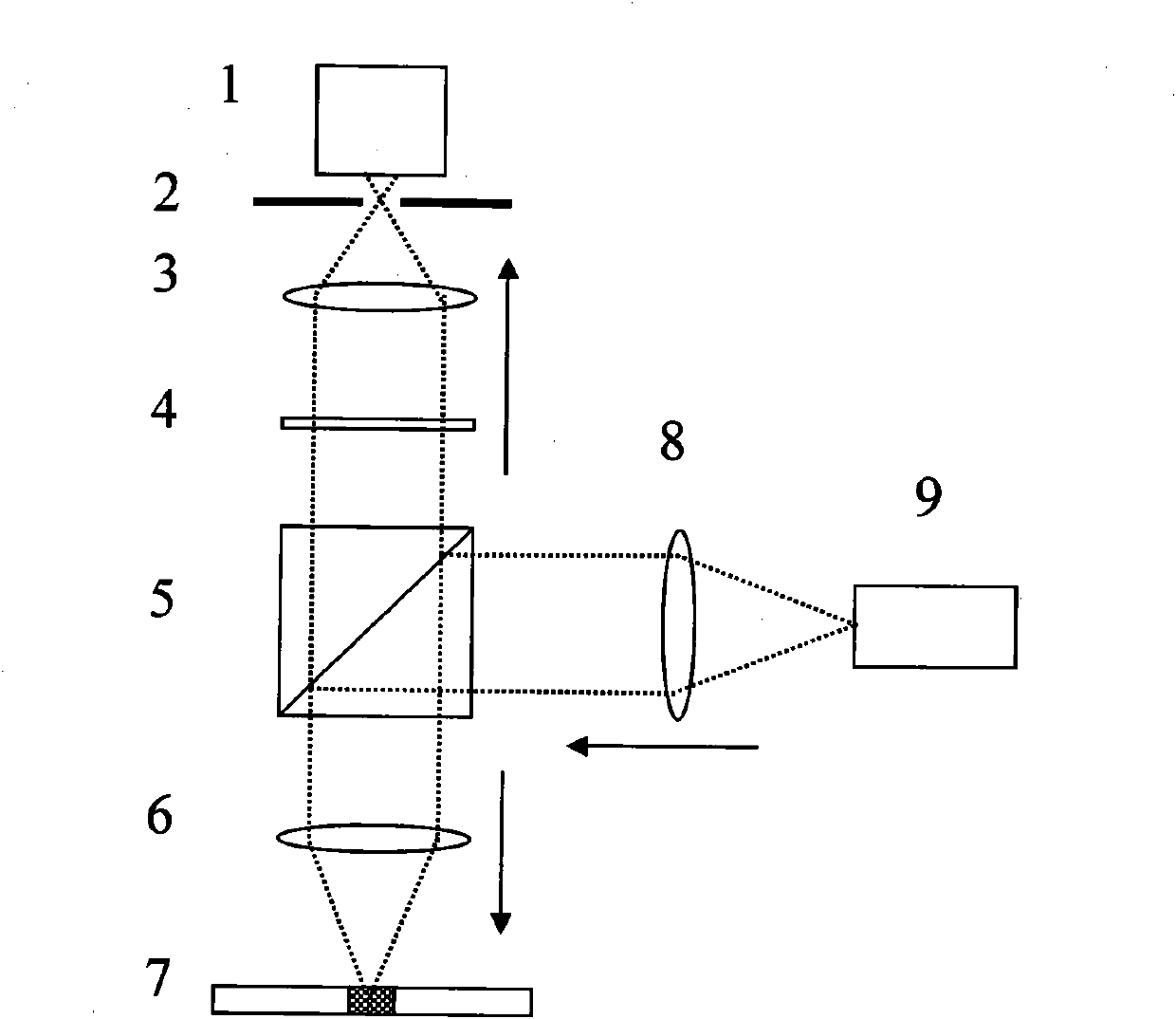

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

[0018] The use of organic polymers as substrate materials for electrophoretic chips requires the materials to have certain mechanical properties and chemical inertness. In order to meet the needs of optical detection, the material should have good optical transparency in the visible (and near-infrared) band. Common materials meeting the above requirements are polymethyl methacrylate (PMMA) and polydimethylsiloxane (PDMS). Electrophoretic chips can be fabricated by injection molding, impression molding, and casting.

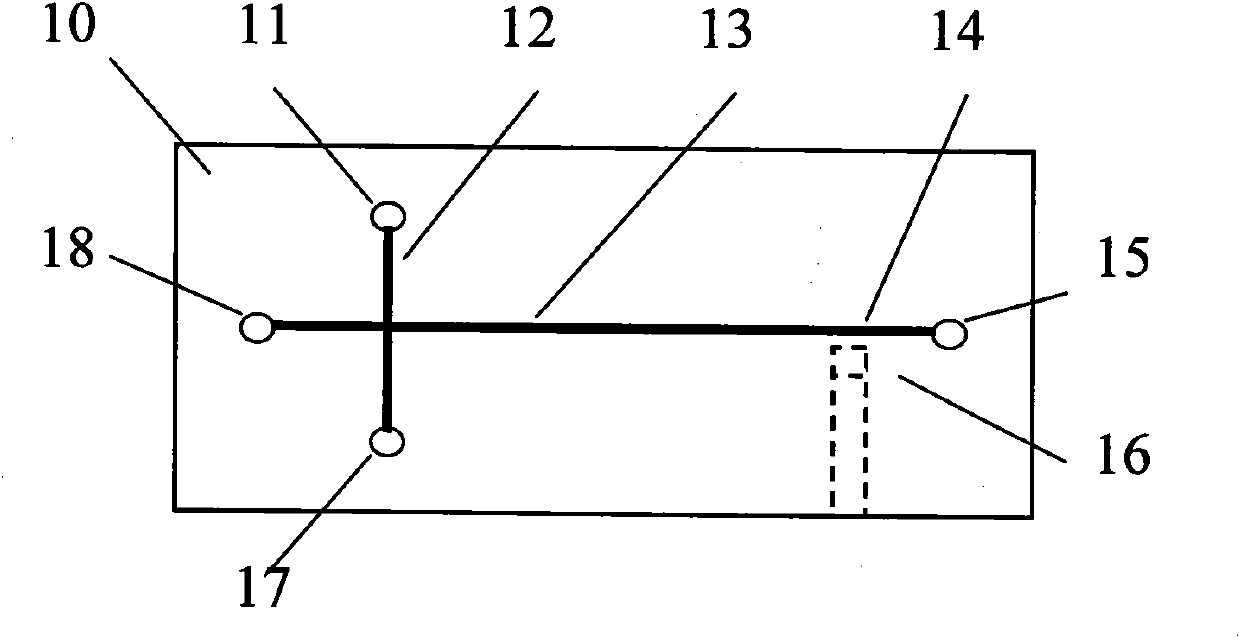

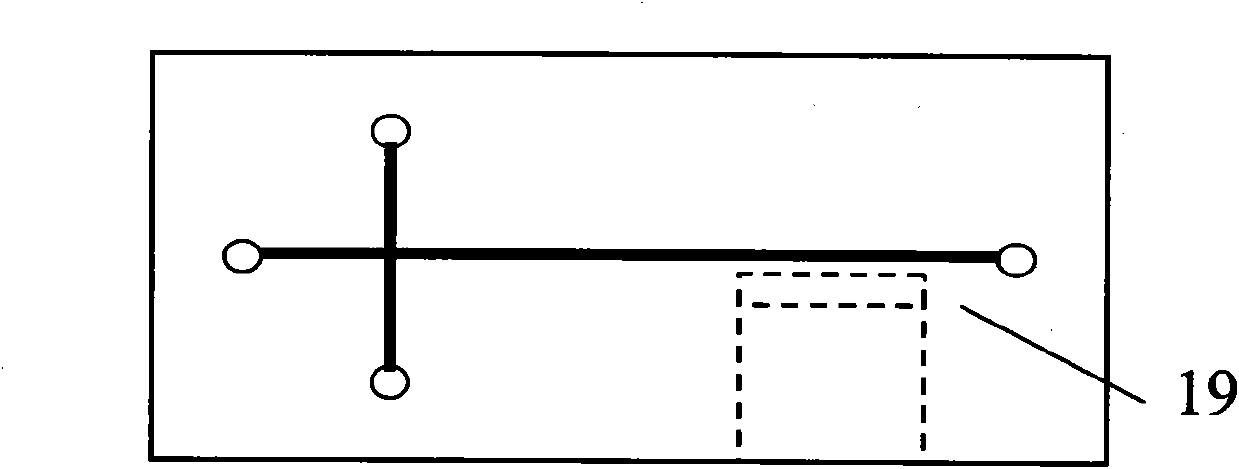

[0019] The separation microstructure on the electrophoresis chip is the same as that of the general electrophoresis chip, such as Figure 2 and Figure 3 top view. The separation microstructure mainly includes the separation channel 13 and intersects with it (including cross structure or double T structure, etc., Figure 2 and Figure 3 Shown are the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com