Groove MOSFET (Metal-Oxide Semiconductor Field Effect Transistor) device and making method thereof

A trench and trench gate technology is applied in the field of trench MOSFET devices and their manufacturing, which can solve problems such as over-etching, and achieve the effects of reducing Rds, reducing Qgd, and avoiding short-circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The invention is explained in more detail below with reference to the accompanying drawings, in which preferred embodiments of the invention are shown. The invention can, however, be embodied in different ways and should not be limited to the embodiments described herein. For example, the description here refers more to N-channel trench MOSFETs, but clearly other devices are possible.

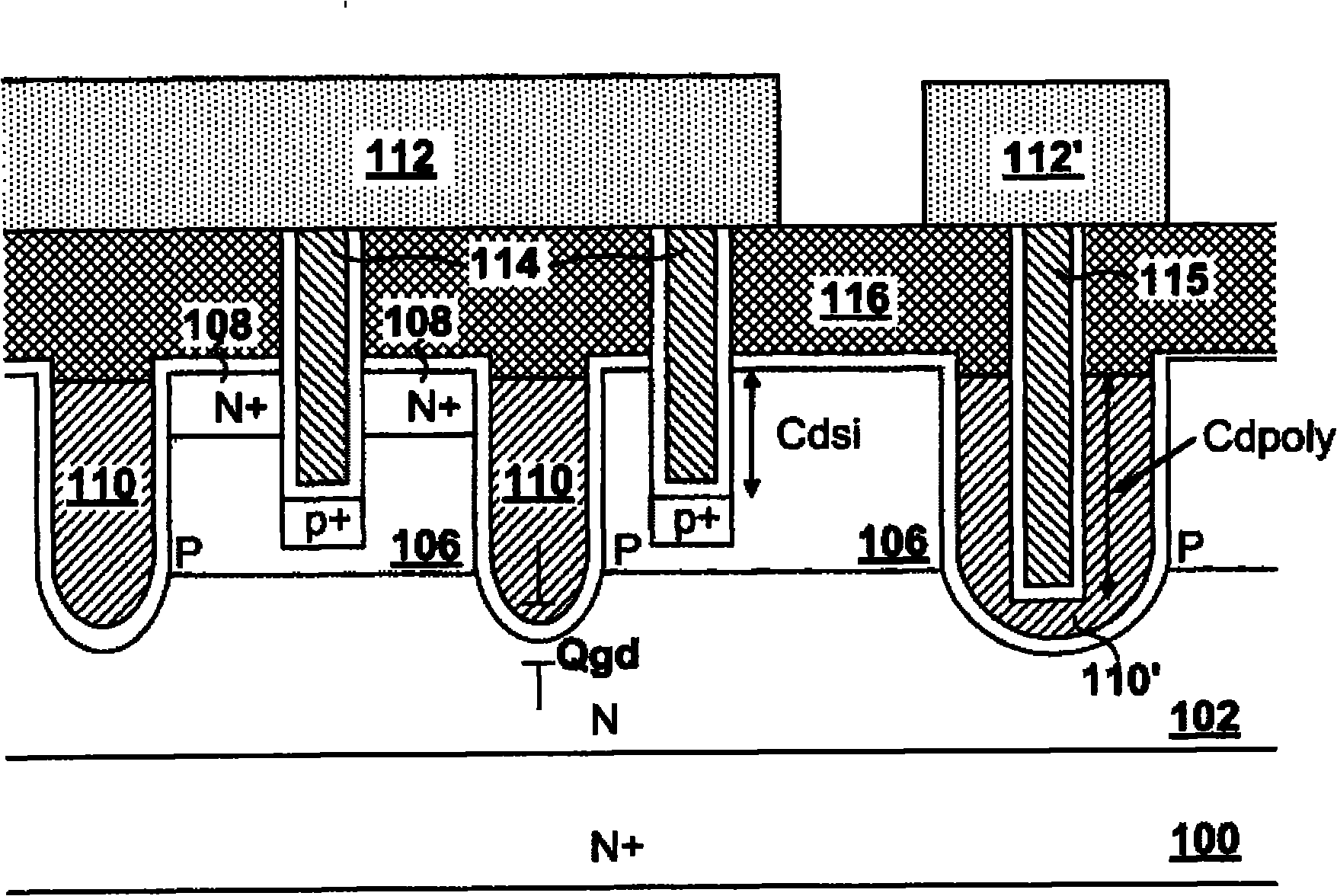

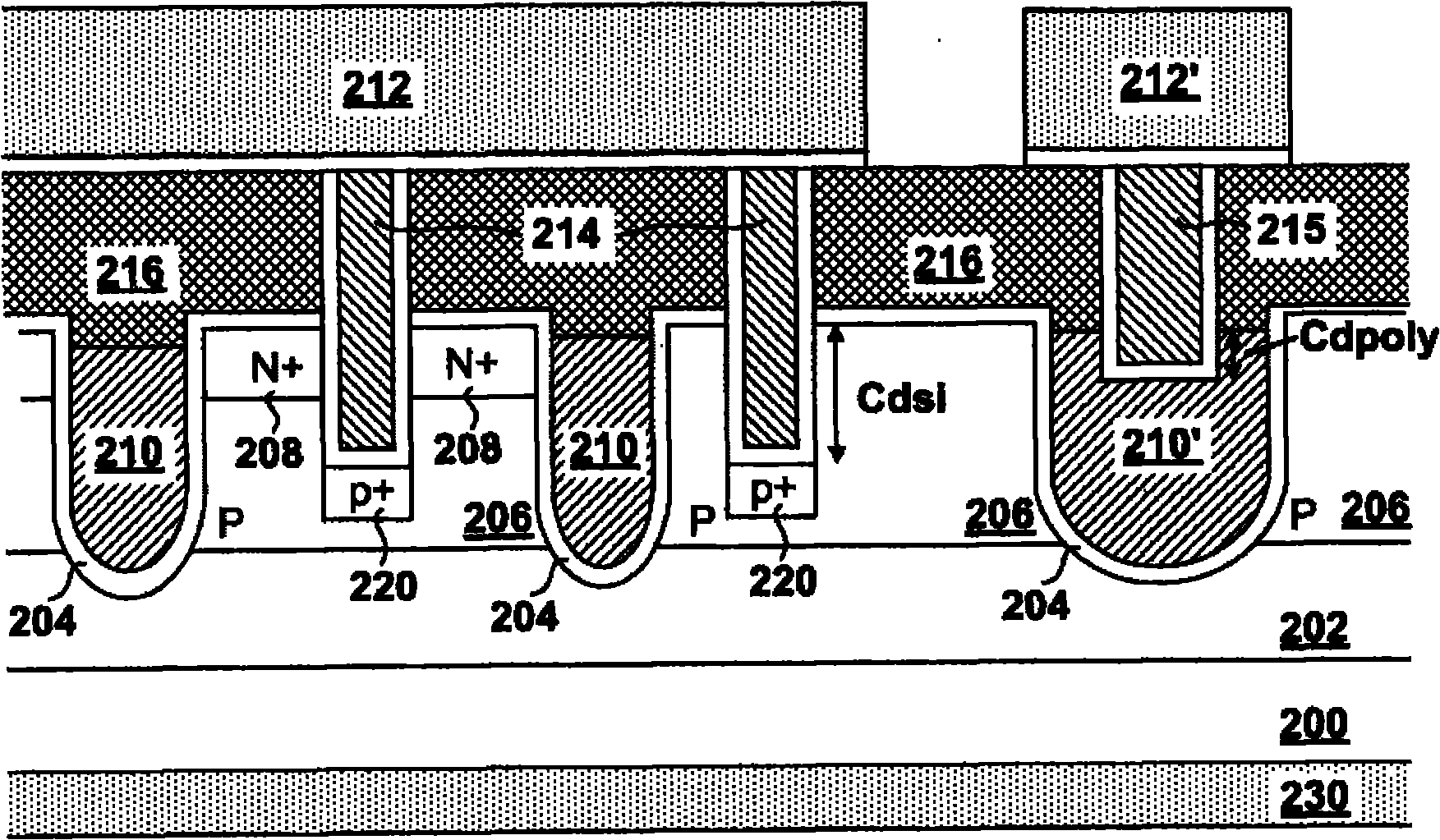

[0056] refer to figure 2 A preferred embodiment of the invention is shown. The N-channel trench MOSFET according to the preferred embodiment is formed on an N+ doped substrate 200, and a drain metal layer 230 is deposited on the lower surface of the substrate. The N-type epitaxial layer 202 is formed on the upper surface of the substrate 200 and has a lower majority carrier concentration than the substrate. In the epitaxial layer 200, a plurality of gate trenches 210 located in the active region and at least one wider gate trench 210' for gate contact are formed, and the trenches in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com