Ceramic powder composition and slurry, catalyst and carrier as well as preparation method and application

A technology of ceramic catalyst and ceramic powder, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, molecular sieve catalyst, etc. It can solve the problems of low reaction conversion rate, deactivation phenomenon, and limited range of simultaneous increase of pore size and specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

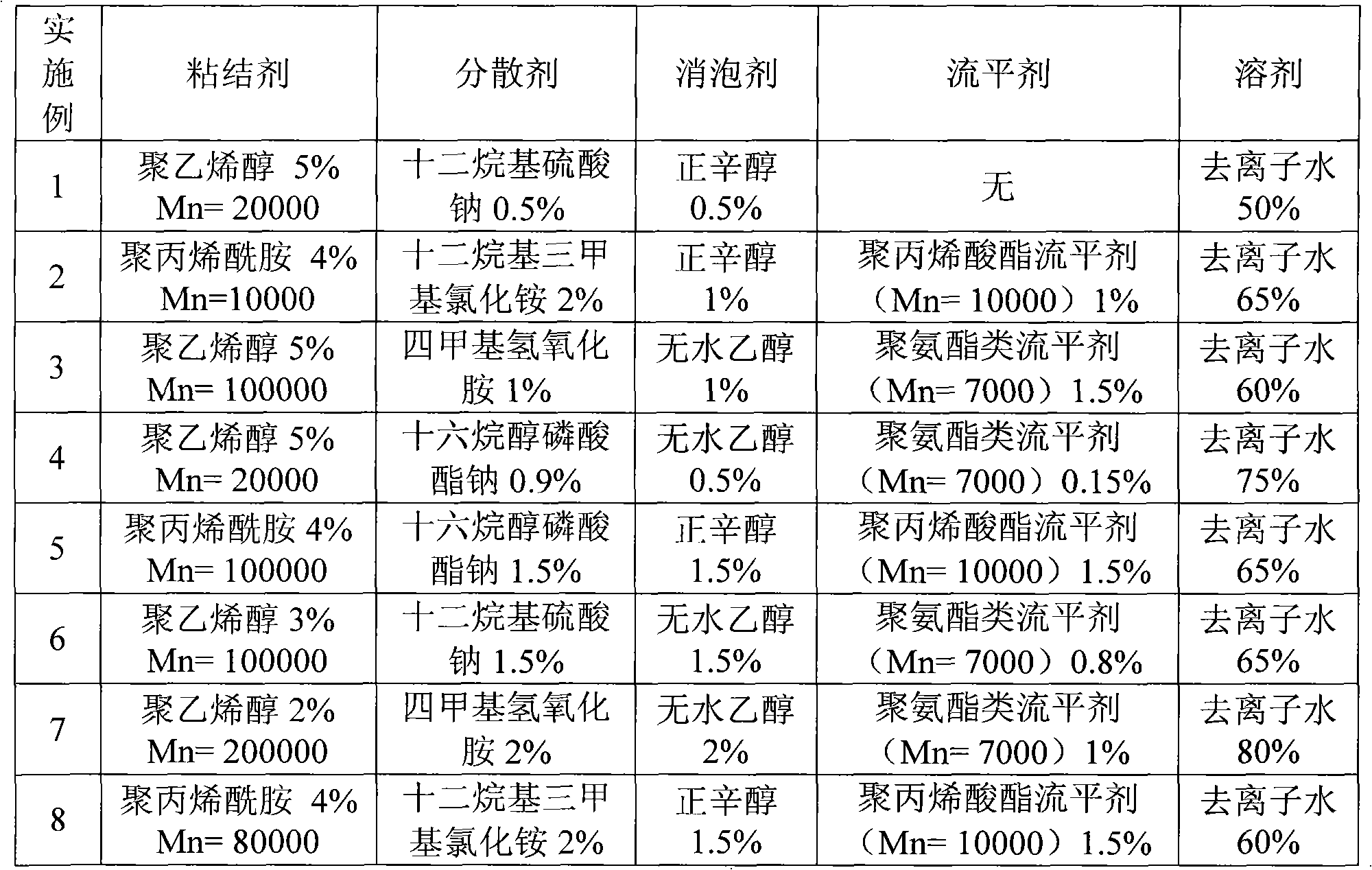

[0062] The preparation method of polyacrylate leveling agent in table 2 is:

[0063] It is prepared by radical polymerization of butyl acrylate and glycidyl methacrylate, and the mass ratio of butyl acrylate to glycidyl methacrylate is 1:1.4. The polymerization initiator is benzoyl peroxide, the dosage of the initiator is 0.015wt%, and the solvent is toluene. The polymerization temperature is 130° C., the polymerization time is 2 hours, and vacuum drying is performed after stopping the reaction.

[0064] The preparation method of polyurethane leveling agent is:

[0065] Mass ratio is 3: 1 toluene diisocyanate and number average molecular weight are 1000 adipic acid-1,4 butanediol polyester diol reaction, catalyzer is dibutyltin dilaurate, catalyst consumption 0.02wt%, reaction temperature is 80°C, the reaction time is 5h, after the reaction, add 3wt% dimethylol propionic acid to extend the chain, dilute with 20% acetone, keep the temperature at 50-60°C, stir for 2h and then ...

Embodiment 1

[0067] (1) Ceramic powder composition

[0068] According to the formulation in Table 1, the ceramic powder composition was obtained after simply mixing each component.

[0069] (2) Ceramic slurry

[0070] After mixing the ceramic powder composition in step (1) with binder, dispersant, defoamer and solvent according to the formula in Table 2, adjust the pH value to 11, stir for 3 hours, and prepare ceramic slurry.

[0071] (3) Ceramic catalyst carrier

[0072] Select 32PPI flexible polyurethane foam, process it into a size of 5×5×5mm, put it in absolute ethanol for 50 minutes of ultrasonic treatment, take it out and dry it at 70°C for 2 hours, and use it as a hard templating agent.

[0073] Sodium dodecylbenzenesulfonate is selected as the soft templating agent, the ceramic slurry is mixed with the soft templating agent, the mixing mass ratio of the ceramic slurry and the soft templating agent is 20:1, and the mixture is uniformly mixed. Put the flexible polyurethane foam in...

Embodiment 2

[0076] (1) Ceramic powder composition

[0077] According to the formulation in Table 1, the ceramic powder composition was obtained after simply mixing each component.

[0078] (2) Ceramic slurry

[0079] According to the formula in Table 2, after mixing the ceramic powder composition in step (1) with binder, dispersant, defoamer, leveling agent and solvent, adjust the pH value to 11, stir for 3 hours, and make a ceramic slurry material.

[0080] (3) Ceramic catalyst carrier

[0081] Sodium dodecylbenzene sulfate is selected as the soft templating agent, the ceramic slurry is mixed with the soft templating agent, the mixing mass ratio of the ceramic slurry and the soft templating agent is 15:1, and the mixture is obtained by mixing evenly.

[0082] 50 μm carbon black was selected as the hard template agent, and the carbon black was placed in absolute ethanol for 30 minutes of ultrasonic treatment, taken out and dried at 70°C for 3 hours before use.

[0083] Mix carbon blac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com