Miniature bonding permanent magnet and production method thereof

A bonded permanent magnet, miniature technology, applied in permanent magnets, inductance/transformer/magnet manufacturing, electrical components, etc. Magnet dimensional accuracy and other issues, to achieve the effect of size reduction, easy demolding, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

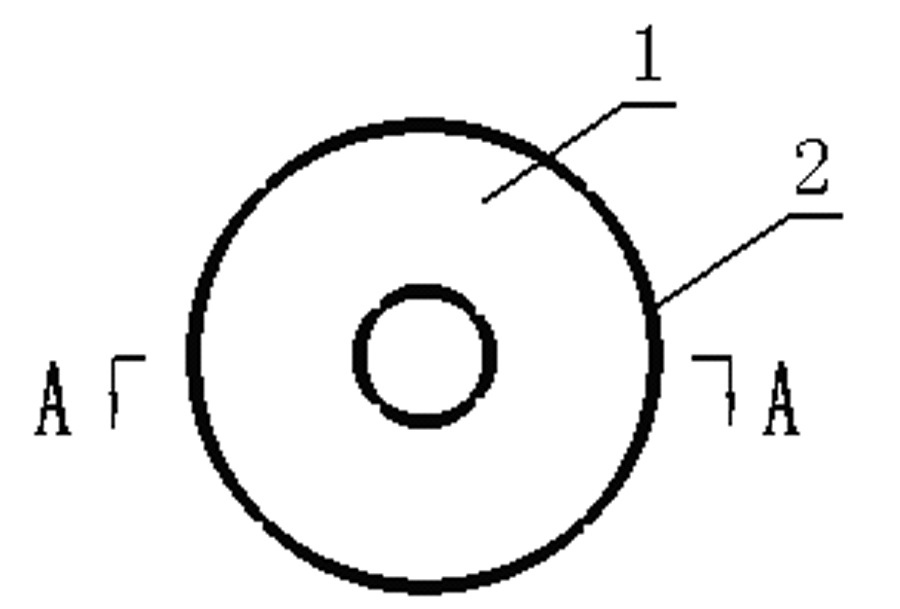

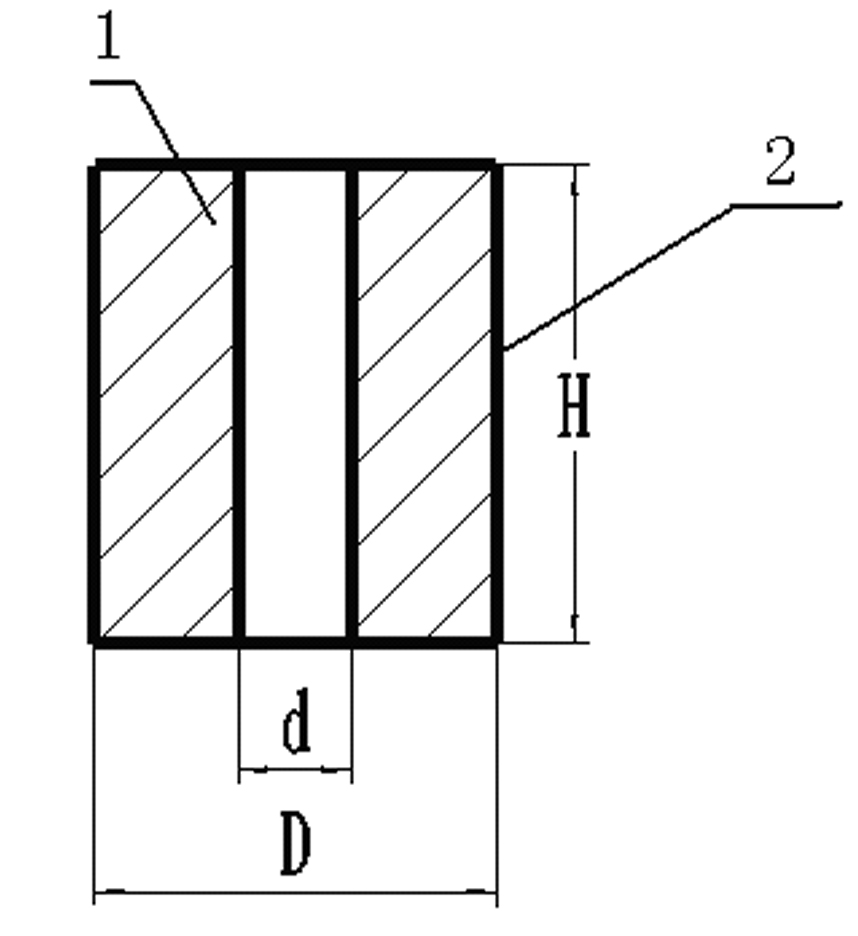

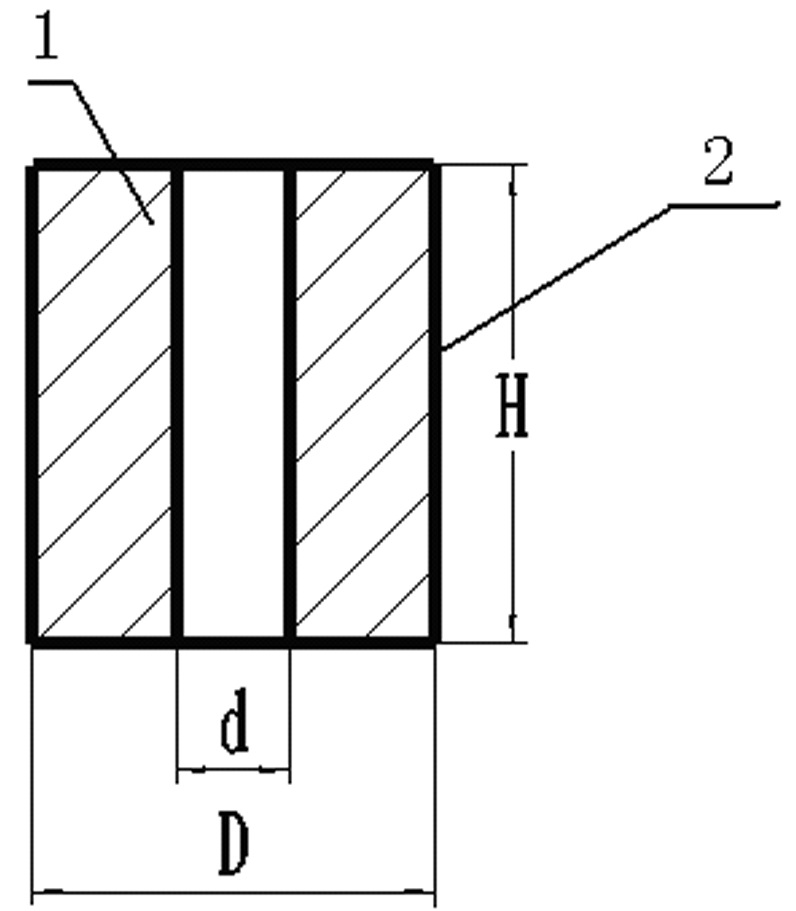

[0020] Example 1: Magnet for digital camera shutter motor

[0021] With reference to accompanying drawing: the shape that the magnet requirement of the digital camera shutter motor of the present embodiment is cylindrical, it is made of cylindrical magnet compact 1 and the anticorrosion coating 2 on the outside of magnet compact, and cylindrical hollow tube The inner diameter d of the cylinder is Φ0.4mm, the outer diameter D of the cylinder is Φ2.1mm, the height H is 2.5mm, and the maximum magnetic energy product (BH)max is 192~200kJ / m 3 .

[0022] The raw material of the magnetic powder is MQA-38-14 anisotropic NdFeB magnetic powder, the binder is CYD-010 epoxy resin, the antioxidant is phenolic 1010 antioxidant, and the lubricant is molybdenum disulfide.

[0023] The preparation method is:

[0024] (1) According to the ingredients of magnetic powder 97.4wt%, binder 2.1wt%, antioxidant 0.2wt%, lubricant 0.3wt%, and mix the above four components evenly;

[0025] (2) Put the...

Embodiment 2

[0031] Example 2: Magnet for automatic zoom motor of digital video camera

[0032] The raw material of the magnetic powder is MQP-B+ isotropic NdFeB magnetic powder, the binder is 2402# phenolic resin, the antioxidant is dilauryl thiodipropionate, and the lubricant is zinc stearate.

[0033] The preparation method is:

[0034] (1) According to the ingredients of magnetic powder 96.8wt%, binder 2.4wt%, antioxidant 0.6wt%, lubricant 0.2wt%, and mix the above four components evenly;

[0035] (2) Put the mixture into the mold of the cylindrical magnet compact. The mold in this embodiment is a cemented carbide mold. The specifications of the selected mold are to control the outer diameter D of the green compact to Φ3.5mm, and the inner diameter d is Φ0.9mm, height H is 6.2mm, molded under the pressure of 1000MPa to make green compact 1, the precision of the forming mold is ≤0.1μm, the positioning accuracy of the mold is ≤0.2μm, and the vibration frequency of the mandrel when filli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com