Preparation method of photoassisted sol-gel of yttrium doped zinc oxide transparent conductive film

A technology of transparent conductive film and zinc oxide is applied in the field of preparation of photoprosol-gel to achieve the effects of being suitable for mass production, low production cost and improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

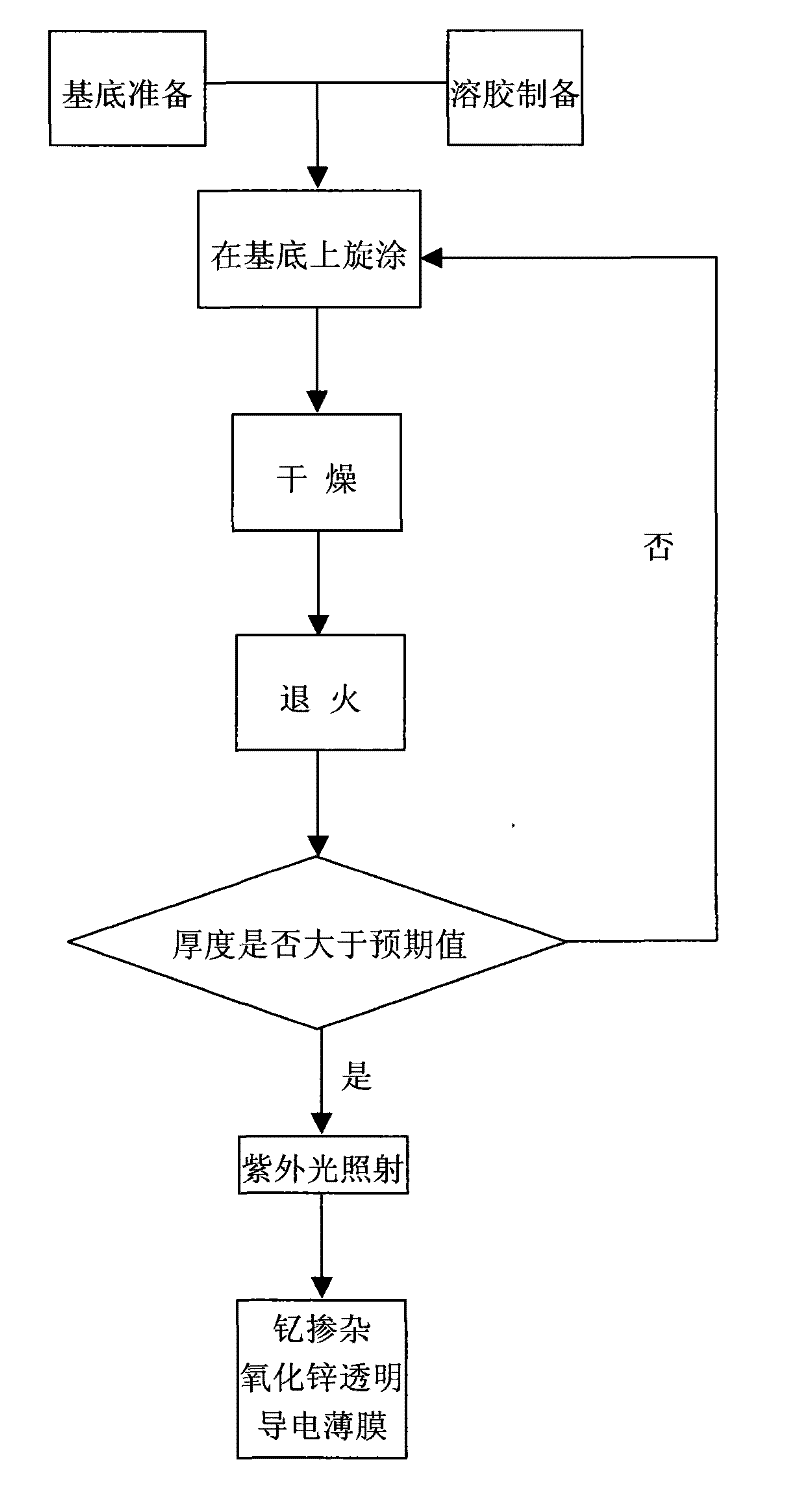

[0022] See figure 1 .

[0023] (1) Preparation of sol: Weigh 2.2g of zinc acetate in a 50mL Erlenmeyer flask, add 19.4mL of ethylene glycol monomethyl ether and 0.6mL of ethanolamine, stir and heat in a water bath at 70°C for 1 hour, and transfer to the Erlenmeyer flask Add 0.1149g yttrium nitrate (doping amount 3.0%) in, continue to heat and stir for 2 hours, obtain transparent and clear sol, it is standby after being cooled to room temperature;

[0024] (2) Cleaning of the glass substrate: wash the ordinary glass with detergent, 3mol / L H 2 SO 4 Solution, 1mol / L NaOH solution, deionized water, acetone, absolute ethanol ultrasonic cleaning;

[0025] (3) Preparation of thin film: apply the sol obtained in step (1) to the glass substrate cleaned by step (2) by spin coating; then dry the glass substrate coated with sol on a heating plate at 80°C After 10 minutes, place it in a muffle furnace at 450°C for 2 minutes and repeat the above sol coating, drying and annealing ten tim...

Embodiment 2

[0033] (1) Preparation of sol: Weigh 2.2g of zinc acetate in a 50mL Erlenmeyer flask, add 19.4mL of ethylene glycol monomethyl ether and 0.6mL of ethanolamine, stir and heat in a water bath at 70°C for 1 hour, and transfer to the Erlenmeyer flask Add 0.0192g yttrium nitrate (doping amount 0.5%) to , continue heating and stirring for 2 hours to obtain a transparent and clear sol, which is cooled to room temperature for subsequent use;

[0034] (2) Cleaning of the glass substrate: wash the ordinary glass with detergent, 3mol / L H 2 SO 4 Solution, 1mol / L NaOH solution, deionized water, acetone, absolute ethanol ultrasonic cleaning;

[0035] (3) Preparation of thin film: apply the sol obtained in step (1) to the glass substrate cleaned by step (2) by spin coating; then dry the glass substrate coated with sol on a heating plate at 80°C After 10 minutes, place it in a muffle furnace at 450°C for 2 minutes and repeat the above sol coating, drying and annealing ten times to obtain a ...

Embodiment 3

[0043] (1) Preparation of sol: Weigh 2.2g of zinc acetate in a 50mL Erlenmeyer flask, add 19.4mL of ethylene glycol monomethyl ether and 0.6mL of ethanolamine, stir and heat in a water bath at 70°C for 1 hour, and transfer to the Erlenmeyer flask Add 0.1915g yttrium nitrate (doping amount 5.0%) in, continue heating and stirring for 2 hours, obtain transparent and clear sol, after cooling to room temperature, set aside;

[0044] (2) Cleaning of the glass substrate: wash the ordinary glass with detergent, 3mol / L H 2 SO 4 Solution, 1mol / L NaOH solution, deionized water, acetone, absolute ethanol ultrasonic cleaning;

[0045] (3) Preparation of thin film: apply the sol obtained in step (1) to the glass substrate cleaned by step (2) by spin coating; then dry the glass substrate coated with sol on a heating plate at 80°C After 10 minutes, place it in a muffle furnace at 450°C for 2 minutes and repeat the above sol coating, drying and annealing ten times to obtain a film with a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com