Method for preparing diethylene glycol dibenzoate plasticizer

A polyol benzoate and polyol technology, applied in the field of rubber additives, can solve the problems of slow reaction temperature, high raw material price, poor compatibility and durability, etc., and achieve good compatibility and durability , Shorten the reaction time, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

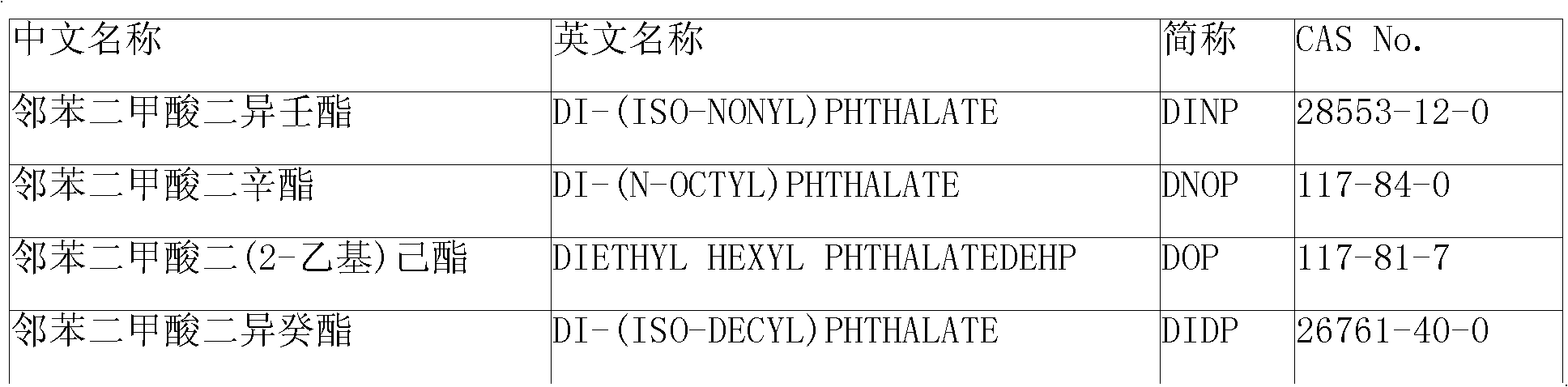

Problems solved by technology

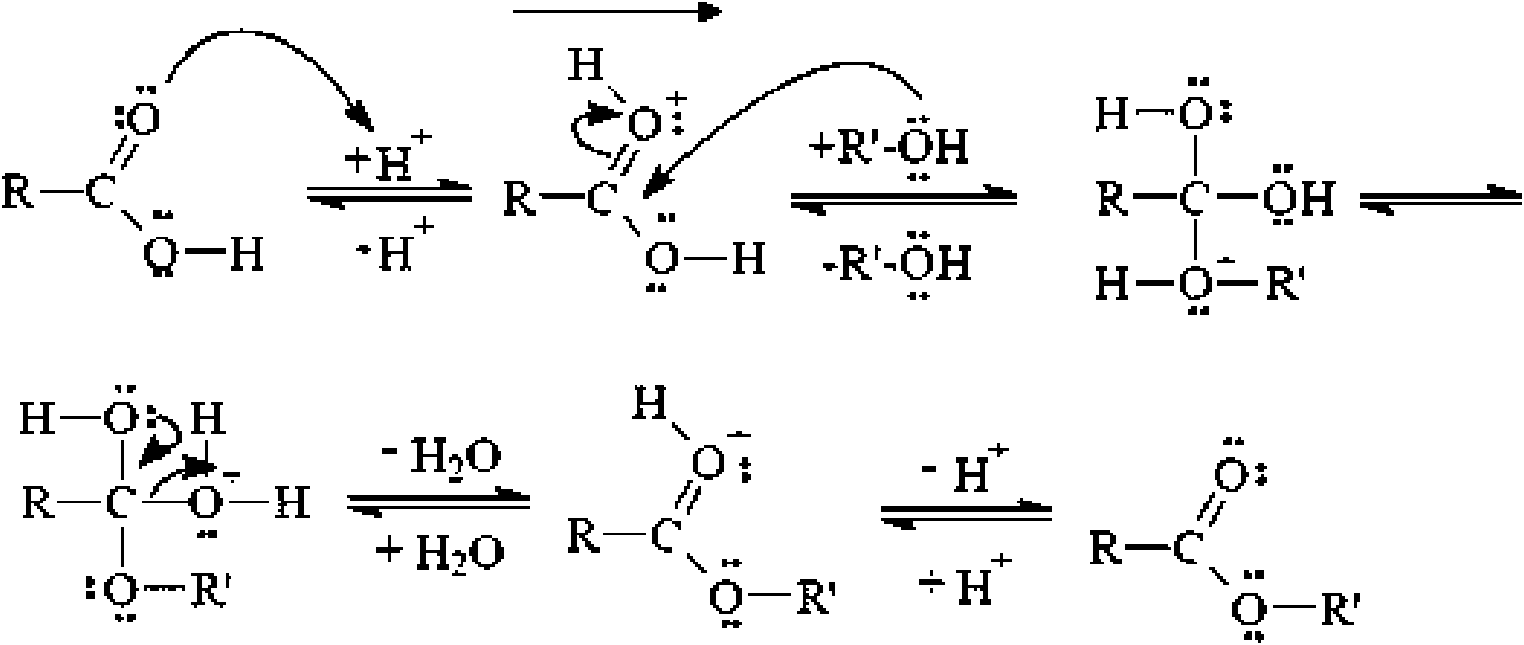

Method used

Image

Examples

Embodiment 1

[0098] Add 0.55mol of diethylene glycol, 0.45mol of dipropylene glycol, and 0.02mol of glycerol into a reactor with a reflux condensation water separator, and stir evenly; add 0.05mol of sulfuric acid as a catalyst, and 40ml of petroleum ether as a water-carrying agent; add 2.06 mol benzoic acid; heat under stirring, adjust the temperature to 90-110°C for 7 hours, separate the water produced by the reaction, and make the reaction complete; when the temperature drops to 70-80°C, add sodium carbonate to remove the acidic catalyst; vacuum separation Recovery of water and water-carrying agents; filtration, that is.

[0099] In this example, the product conversion rate was 96.5%.

Embodiment 2

[0101] Add 0.5mol diethylene glycol, 0.5mol dipropylene glycol, and 0.15mol glycerol into a reactor with a reflux condensation water separator and stir evenly; add 0.04mol p-toluenesulfonic acid as a catalyst, and 50ml heptane as a water-carrying agent; Add 2.45mol benzoic acid; heat under stirring, adjust the temperature to 100-120°C and keep it warm for 6 hours, separate the water produced by the reaction to complete the reaction; when the temperature drops to 70-80°C, add sodium hydroxide to remove the acidic catalyst ; Vacuum separation and recovery of water and water-carrying agents; filtration, that is.

[0102] In this example, the product conversion rate was 97.2%.

Embodiment 3

[0104] Add 0.45mol of diethylene glycol, 0.55mol of dipropylene glycol, and 0.2mol of glycerol into a reactor with a reflux condensation water separator and stir well; add 0.03mol of phosphoric acid and 0.02mol of phosphotungstic acid as a catalyst, and 52ml of n-hexane as a belt Water agent; add 2.6mol benzoic acid; heat under stirring, adjust the temperature to 110-130°C for 9 hours, separate the water produced by the reaction, and make the reaction complete; when the temperature drops to 70-80°C, add calcium hydroxide Remove the acidic catalyst; vacuum separation and recovery of water and water-carrying agent; filter, that is.

[0105] In this example, the product conversion rate was 97.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com