Extracting and processing technique of carrageen

A processing technology, carrageenan technology, applied in the field of extraction and processing technology, can solve the problems of low transparency and purity of extracted colloid, incomplete dissolution of colloid, slow gelation of carrageenan, etc., to achieve excellent transparency and purity, and inhibit Effects of microbial growth and water content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

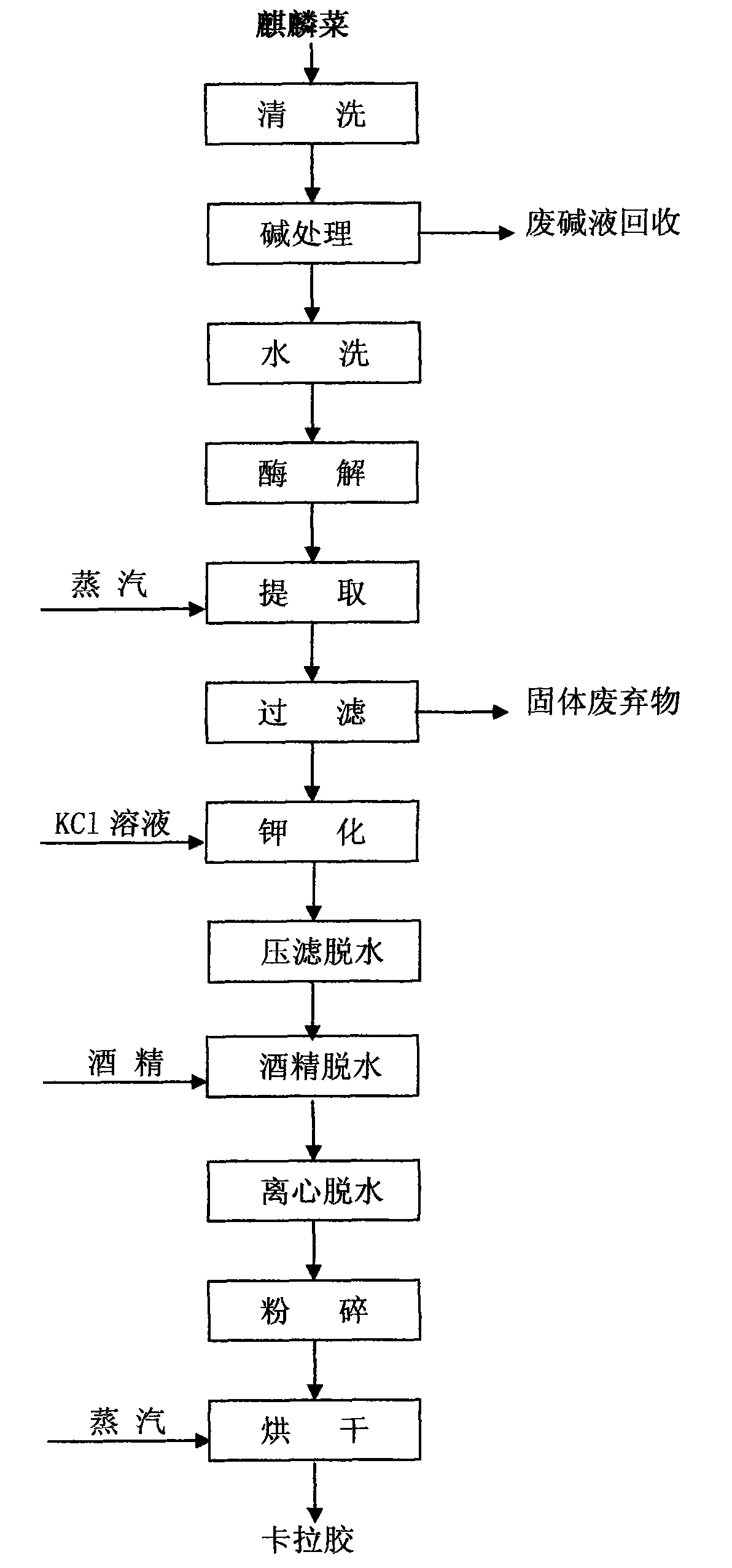

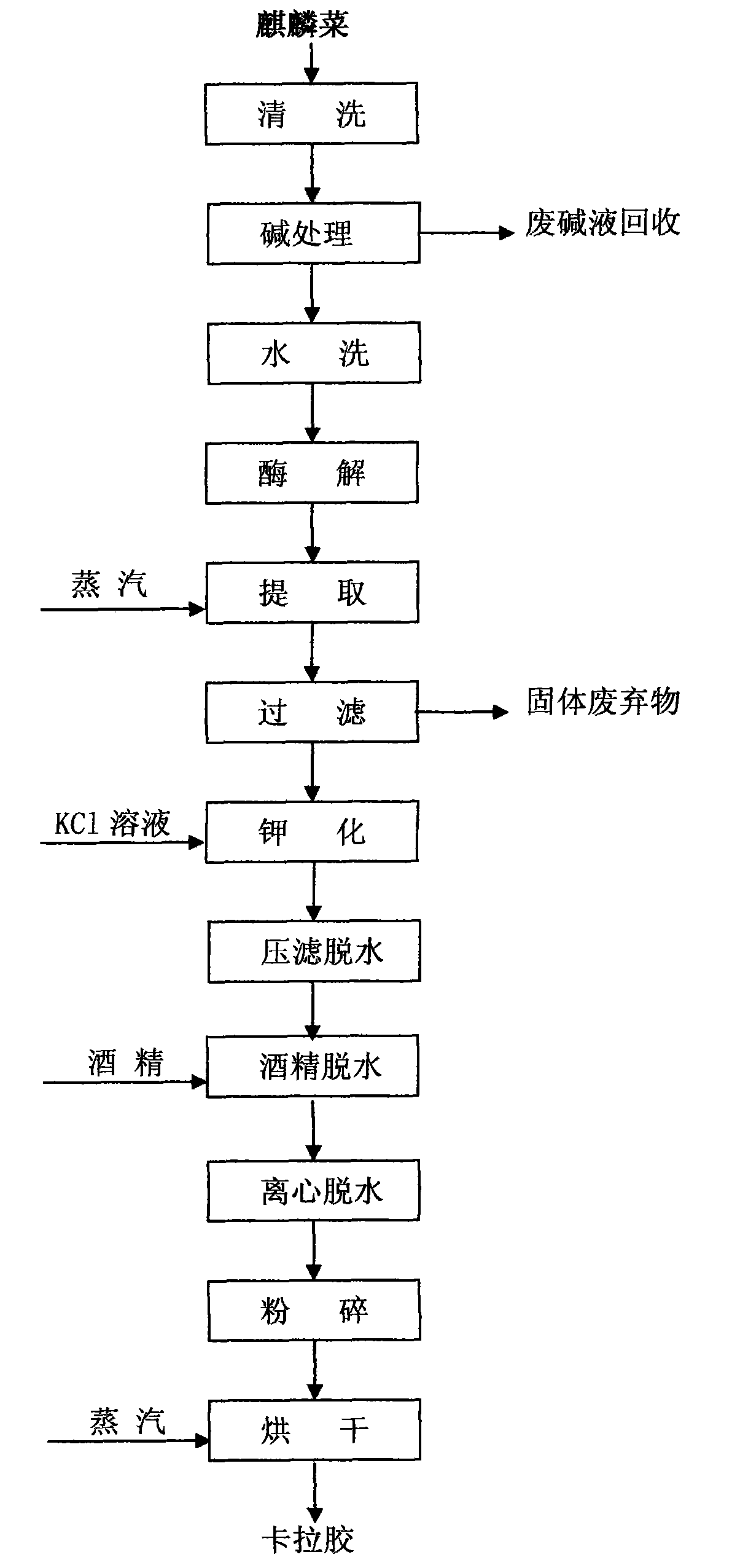

Image

Examples

specific Embodiment 1

[0023] A kind of extraction and processing technology of carrageenan, comprises the steps:

[0024] (1) Cleaning: Soak Eucheuma in 10 times the amount of water and clean it for 3 hours;

[0025] (2) Alkali treatment: Alkali treatment of Eucheuma after cleaning with 8% sodium hydroxide and 5% potassium chloride mixture at 50°C for 15 hours;

[0026] (3) Washing: rinse and soak the Eucheuma after the alkali treatment with water until the pH value is neutral, and adjust the pH value to weak acidity with a concentration of 0.3% hydrochloric acid solution;

[0027] (4) Enzymolysis: soak the washed Eucheuma in hot water, adjust the temperature to 40°C, add 1.0% cellulase, and enzymolyze at 45°C for 1 hour; Enzyme 10 minutes;

[0028] (5) Extraction: boil the enzymatically hydrolyzed Eucheuma gelatin in hot water at 90°C for 1 hour, and keep stirring during the boiling process;

[0029] (6) Filtration: filter the boiled coarse glue solution while hot with a microporous plate-and-f...

specific Embodiment 2

[0036] A kind of extraction and processing technology of carrageenan, comprises the steps:

[0037] (1) Cleaning: Soak Eucheuma in 25 times of water and clean it for 8 hours;

[0038] (2) Alkali treatment: Alkali treatment of the washed Eucheuma with 8% sodium hydroxide and 7% potassium chloride mixture at 50° C. for 10-24 hours;

[0039] (3) Washing: rinse and soak the Eucheuma after the alkali treatment with water until the pH value is neutral, and adjust the pH value to weak acidity with a concentration of 0.3% hydrochloric acid solution;

[0040] (4) Enzymolysis: soak the washed Eucheuma in hot water, adjust the temperature to 60°C, add 1.0% cellulase, and enzymolyze at 50°C for 1 hour; Enzyme 10 minutes;

[0041] (5) Extraction: boil the enzymatically hydrolyzed Eucheuma gelatin in hot water at 90°C for 1 hour, and keep stirring during the boiling process;

[0042] (6) Filtration: filter the boiled coarse glue solution while hot with a microporous plate-and-frame filte...

specific Embodiment 3

[0049] A kind of extraction and processing technology of carrageenan, comprises the steps:

[0050] (1) Cleaning: Soak Eucheuma in 18 times of water and clean it for 5 hours;

[0051] (2) Alkali treatment: Alkali treatment of the washed Eucheuma baicalensis with 7% sodium hydroxide and 6% potassium chloride mixture at 50° C. for 10-24 hours;

[0052] (3) Washing: Rinse and soak the Eucheuma after the alkali treatment with water until the pH value is neutral, and adjust the pH value to weak acidity with a concentration of 0.2% hydrochloric acid solution;

[0053](4) Enzymolysis: soak the washed Eucheuma in hot water, adjust the temperature to 45°C, add 0.8% cellulase, and enzymolyze at 48°C for 1 hour; Enzyme 10 minutes;

[0054] (5) Extraction: boil the enzymatically hydrolyzed Eucheuma gelatin in 80°C hot water for 1 hour, and keep stirring during the boiling process;

[0055] (6) Filtration: filter the boiled coarse glue while it is hot, and the glue content in the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com